sounds like you already have a pretty solid system if your beer is turning out that good!

Thanks - I was kinda thinking that too, but I'm always open to suggestions.

It's a myth. Only heat releases tannins.

Unless you are squeezing hard enough to make diamonds, you'll be fine.

HAHA! The only thing I'll add is FILTER what you squeeze out. Squeezing the grains kinda negates the whole "grain bed as a filter" strategy, so you need to run it through a pretty fine strainer (like a clean grain/paint strainer bag) just to catch what gets out. As you squeeze the bag it'll stretch and let the dust and "flour" escape. That's why I put my strainer inside a bag and pour everything through it even twice to get as much as that stuff out as I can, because what DOES get into the boil can release tannins, and you want to minimize that.

Seriously - I bought 2 large and 2 small paint strainer bags from Home Depot. Cost less than $7 total if I recall. Go get 'em!

That's great to know,thanks! Now another question,any one set up a one gallon profile in the new mobile version of beersmith?

As a matter of fact, yes.

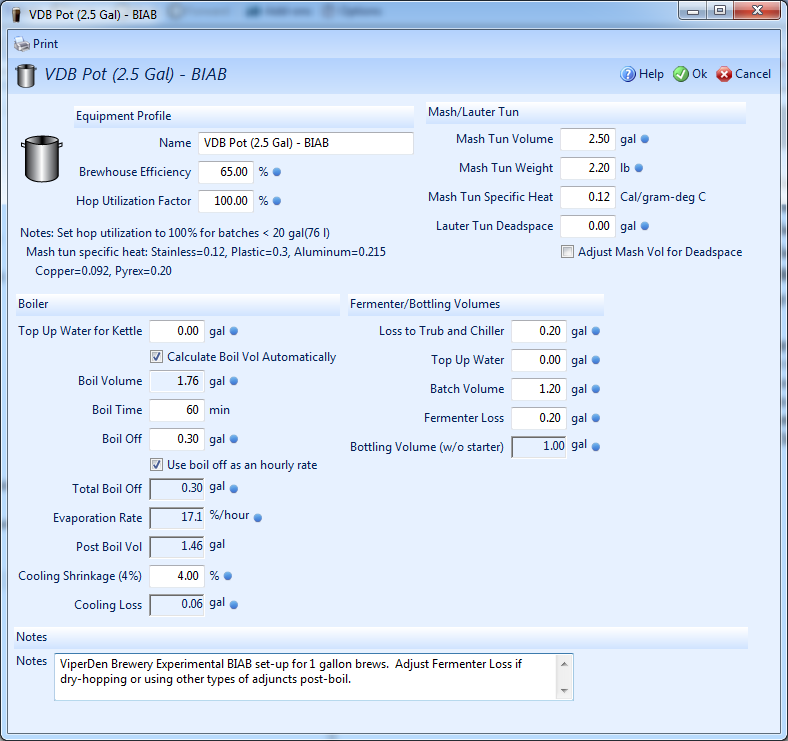

"VBD Pot (2.5 Gal) BIAB" (That's ViperDen Brewery)

Mash Tun Volume 2.5 (I'll make this three when I get a larger pot this weekend)

Weight (Anyone know what use this is?!) 2.2 lb

Specific Heat .12 (Stainless - be sure to adjust if you use an aluminum or other pot. Obviously we're not using plastic.)

Deadspace is zero because we're mashing in the boil pot.

Top up is zero, boil time adjusts of course, boil off I'm still tweaking but I think I'm in the vicinity of .3 to .35 gallons an hour. Loss to Trub and Chiller is .2, top up is 0, batch volume adjusts of course, but I use 1.2, and fermenter loss is .2. You should always consider adjusting the fermenter loss if you're dry-hopping or adding things like cocoa powder, fruit, etc - anything that will soak up beer or simply be impossible to suck out around (leaf hops REALLY burn up some volume...) I've also read that coconut is very absorbant.

Hope this helps. And if it doesn't, here's a screen shot 'cause I'm just that nice...

And of course if anyone has some adjustments to recommend, I'm all ears (er... eyes...)