I've been brewing all grain now for a couple months and i LOVE using my coleman xtreme and batch sparge method. I would like to recirculate my mash and thought of this design that would make use of my current setup. My only question is, would this work?

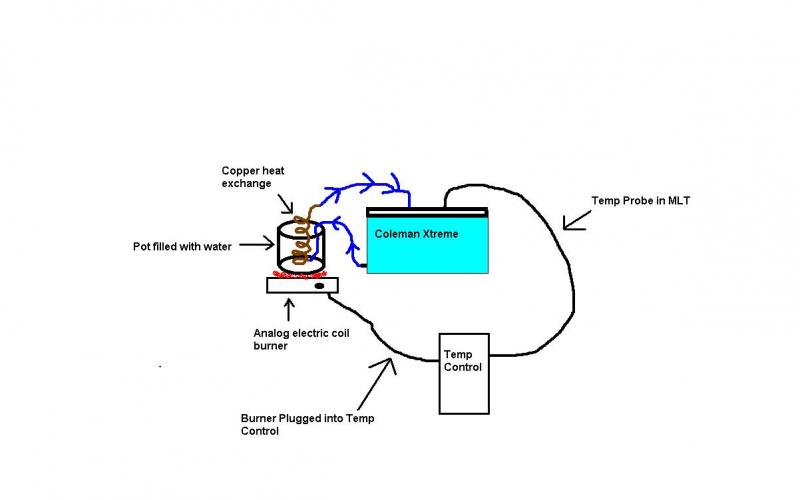

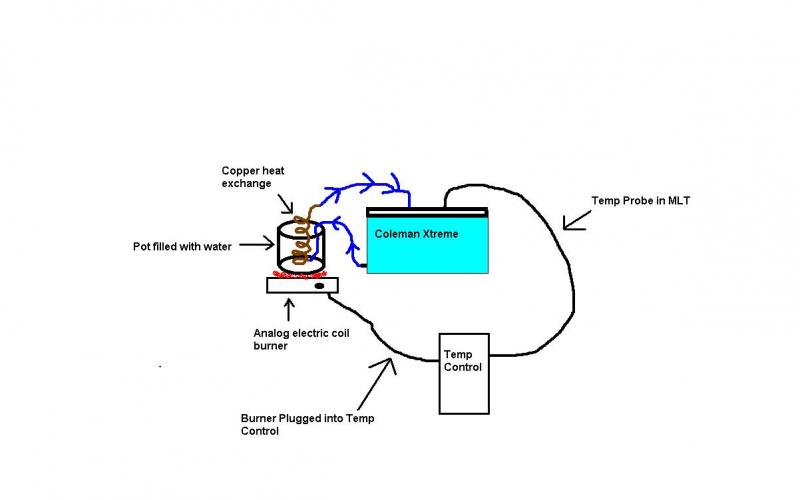

Basically the idea is to pump the mash through a copper heat exchange that is submerged into a pot filled with water. the pot sits on top of a standard electric burner that is plugged into a temp controller with the temp probe inside the MLT. I have created a fantastic (not really) illustration. My concern is that this setup wouldn't regulate heat well enough but i'm honestly not sure. I would have to build some type of adjustable arm to distribute the wort evenly back into the MLT but aside from that i'm assuming this is a fairly simple turnkey setup.

Thanks in advance for anyone who replies, I know i came to the right place!

Basically the idea is to pump the mash through a copper heat exchange that is submerged into a pot filled with water. the pot sits on top of a standard electric burner that is plugged into a temp controller with the temp probe inside the MLT. I have created a fantastic (not really) illustration. My concern is that this setup wouldn't regulate heat well enough but i'm honestly not sure. I would have to build some type of adjustable arm to distribute the wort evenly back into the MLT but aside from that i'm assuming this is a fairly simple turnkey setup.

Thanks in advance for anyone who replies, I know i came to the right place!