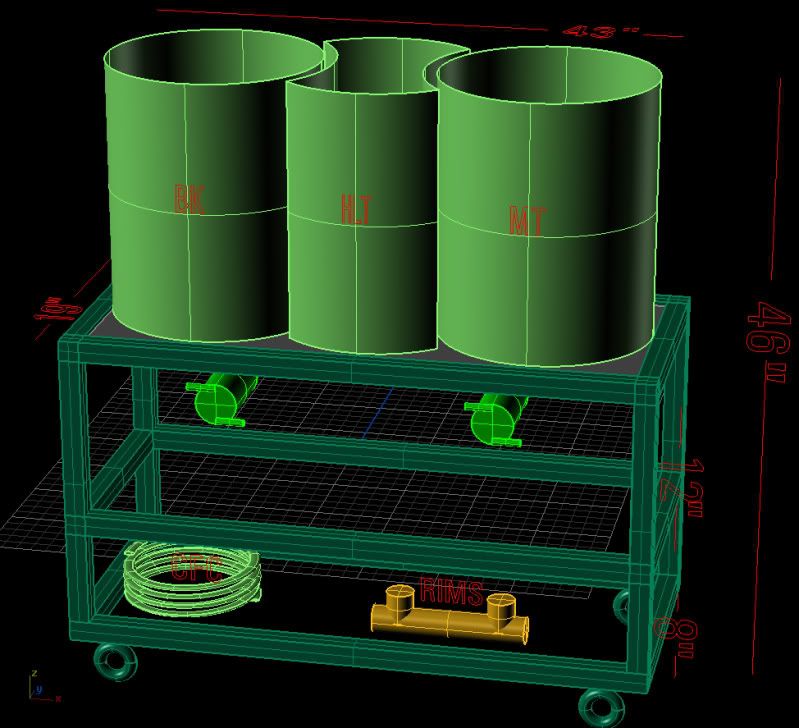

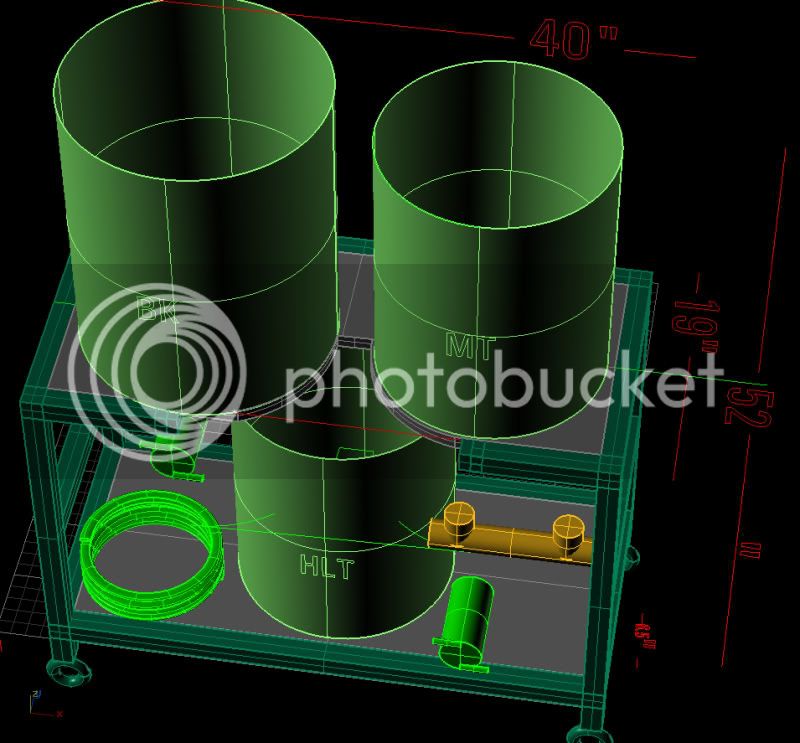

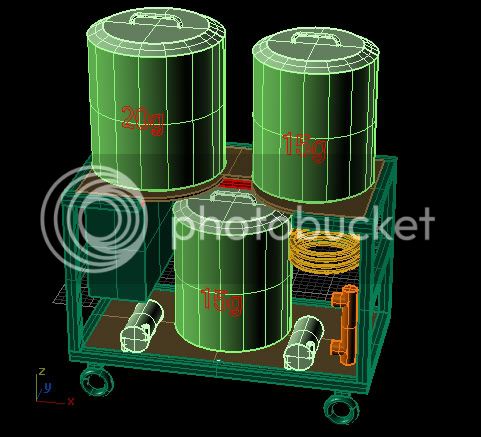

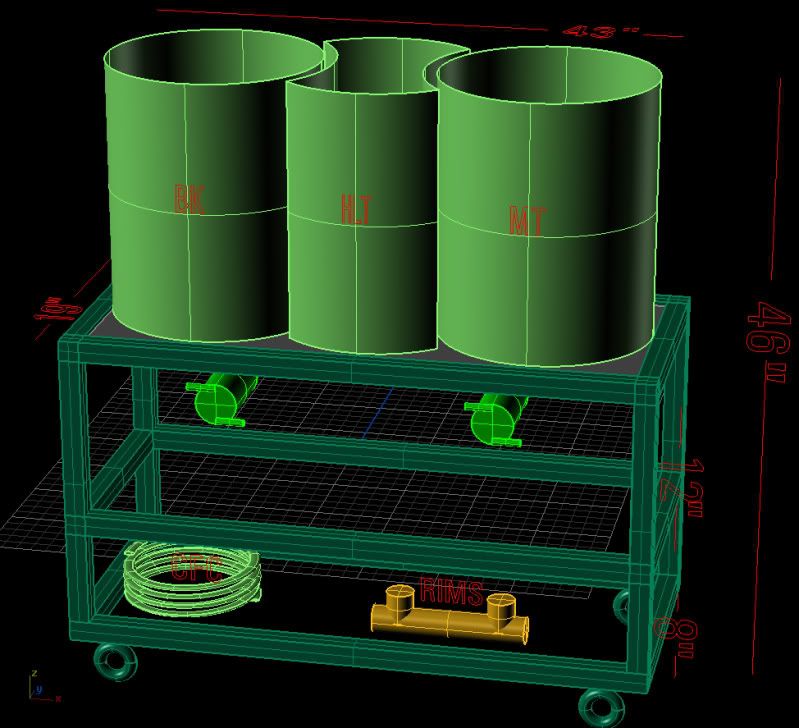

This is the design that I've decided to go with.

Two 15 gal blichmann kettles (that I already have)

A custom concave HLT that is being built by a friend. It shaves off 9 inches from the rig, and just looks cool too.

The same guy thats building my kettle will also build the Stainless stand.

It will be all electric.

I may want to add automation later, but for now, I want it set up as simple as possible . ( many questions to follow)

Two 15 gal blichmann kettles (that I already have)

A custom concave HLT that is being built by a friend. It shaves off 9 inches from the rig, and just looks cool too.

The same guy thats building my kettle will also build the Stainless stand.

It will be all electric.

I may want to add automation later, but for now, I want it set up as simple as possible . ( many questions to follow)