Whats up everyone,

I am in the middle of my Countertop Brutus build and tested out the HLT hooked up to the control panel for the first time. I have run into a couple bumps that I am hoping to get help with. My dad and I wired up the control box with the PID, SSR and 2 outlets for the pump and the HLT. We ran the hot into the box and jumped to everything that needed power with the use of wire nuts. we also used another jumper that had the 2 SSR wires and a hot wire, then hooked it to the HLT outlet. Everything is grounded no problem and the neutral wires seem to be in the right place. When I did my test run, the PID turned on and the probe was holding the proper temp within 2 degrees (I verified with a thermometer). My issue is that the SSR never seemed to open and close. The OUT light on the PID did not light up. When I ran the autotune, the element seemed to heat up as if I plugged it directly into an outlet. I set the autotune for 150 degrees, and when it hit 198 degrees I shut it off figuring that something was wrong. Everything seems to be working great except for the heat to the element not being controlled. I plugged a light into the kettle outlet and it never turned on and off.....just stayed constant which tells me that the SSR may not be working properly. I know if anyone can help me get this thing up and running (safely) it will be you guys. Thanks!

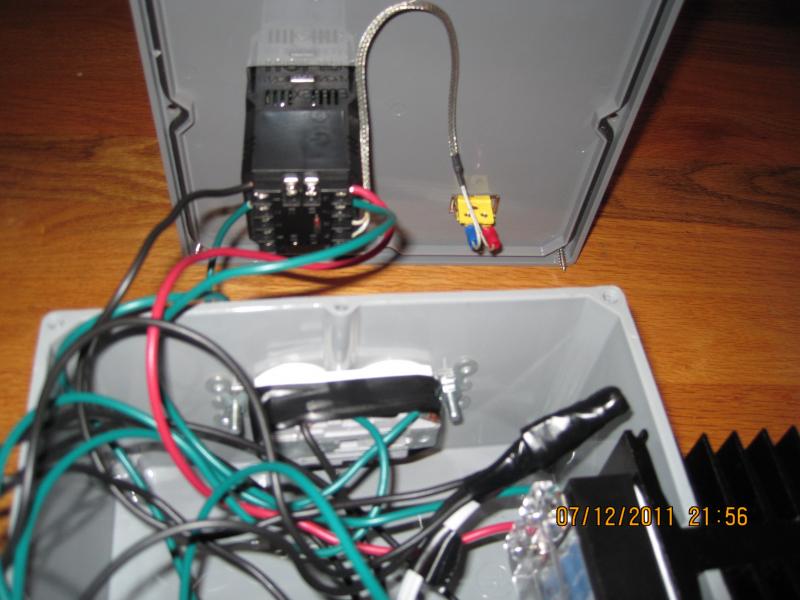

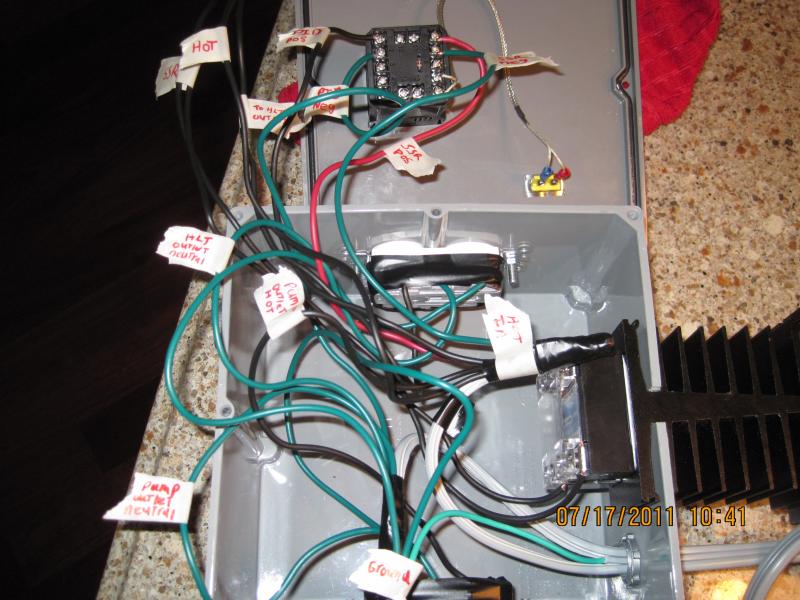

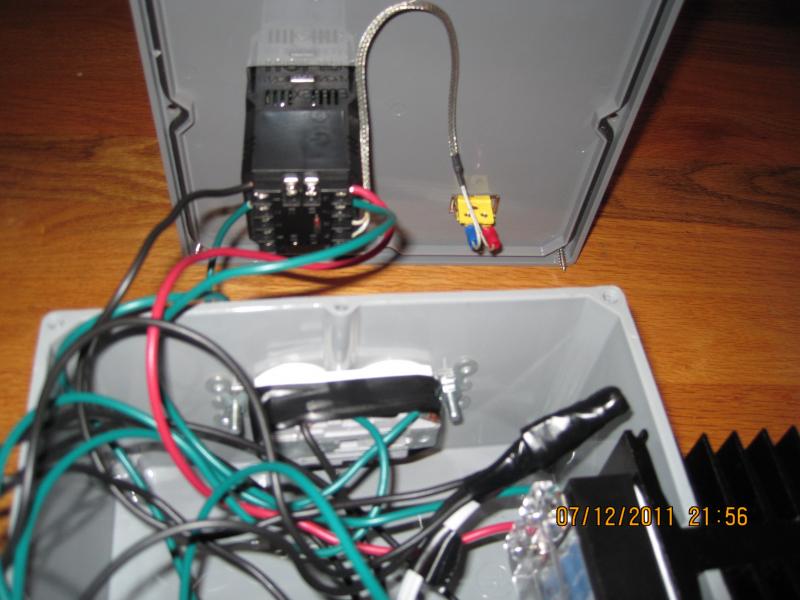

P.S I tried to attach a couple of pictures (hopefully it works lol). The black wires are hot and the SSR wires, and the green wires are neutral and ground.

I am in the middle of my Countertop Brutus build and tested out the HLT hooked up to the control panel for the first time. I have run into a couple bumps that I am hoping to get help with. My dad and I wired up the control box with the PID, SSR and 2 outlets for the pump and the HLT. We ran the hot into the box and jumped to everything that needed power with the use of wire nuts. we also used another jumper that had the 2 SSR wires and a hot wire, then hooked it to the HLT outlet. Everything is grounded no problem and the neutral wires seem to be in the right place. When I did my test run, the PID turned on and the probe was holding the proper temp within 2 degrees (I verified with a thermometer). My issue is that the SSR never seemed to open and close. The OUT light on the PID did not light up. When I ran the autotune, the element seemed to heat up as if I plugged it directly into an outlet. I set the autotune for 150 degrees, and when it hit 198 degrees I shut it off figuring that something was wrong. Everything seems to be working great except for the heat to the element not being controlled. I plugged a light into the kettle outlet and it never turned on and off.....just stayed constant which tells me that the SSR may not be working properly. I know if anyone can help me get this thing up and running (safely) it will be you guys. Thanks!

P.S I tried to attach a couple of pictures (hopefully it works lol). The black wires are hot and the SSR wires, and the green wires are neutral and ground.