I've been browsing this forum for awhile soaking up many great ideas and this is my first post. I want to thank P-J for his schematics. They were very helpful.

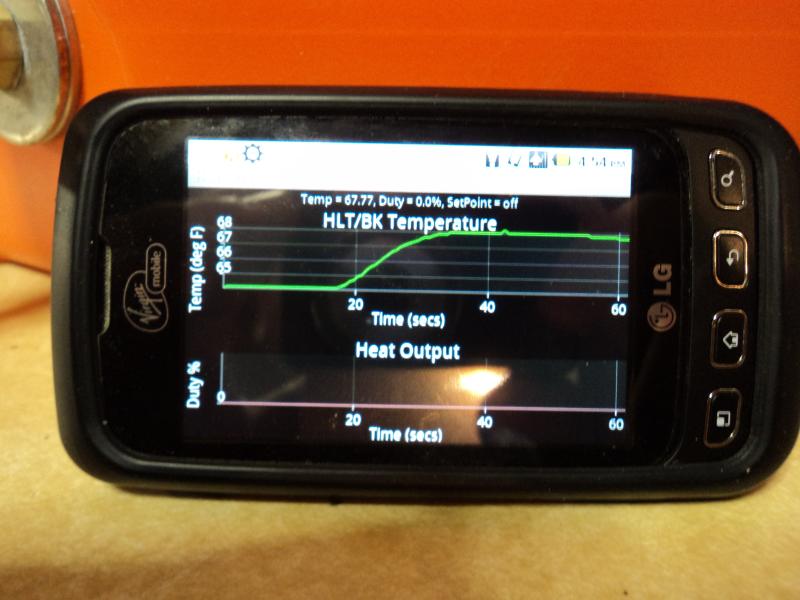

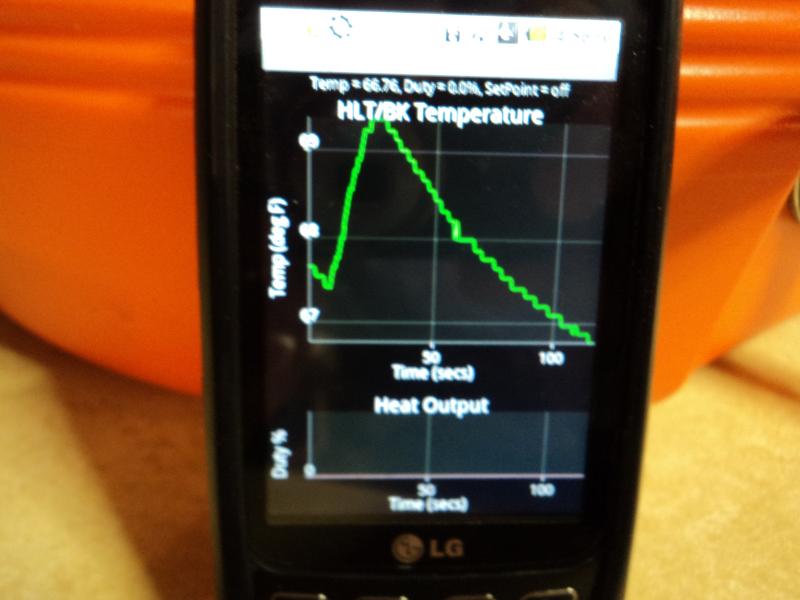

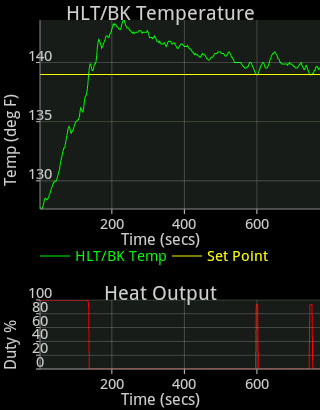

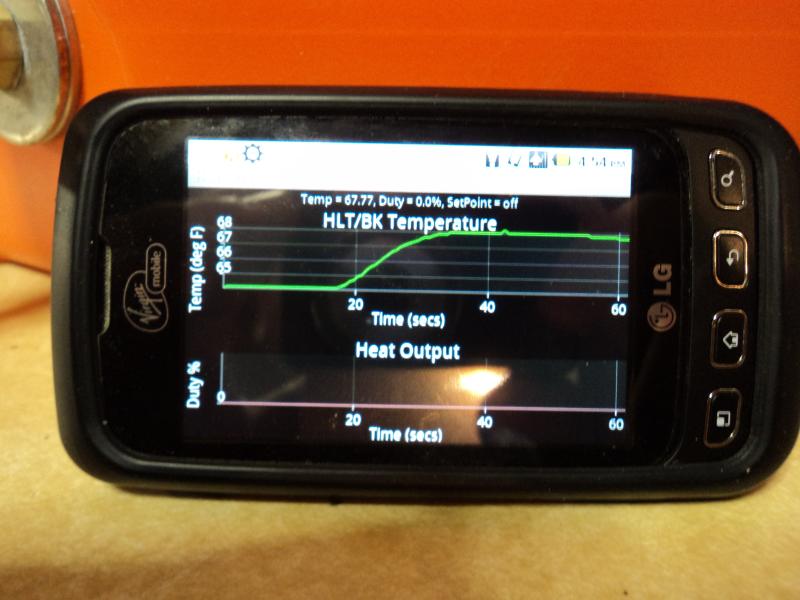

The best location I have to brew is in the basement. I wanted to shorten the brew day waiting for the water to heat up and stop using propane which forces me to lug equipment up and down the cellar steps in order to do it safely. I also wanted to be able to do 10 gallon batches in a limited space while not spending a lot of money. I had a free dryer outlet since we moved the washer and dryer upstairs, so I thought I'd set up an inexpensive electric system. I really liked the panels I see on this board but I'm better with software. Therefore, I created an android app that controls a 220V, 5500 watt heating element in a 15.5 gallon vessel via an Ethernet bridge (a router with custom firmware) and I have a one wire digital sensor in a probe for receiving temperature data. An embedded processor uses a PID algorithm to set to the desired temperature. It has a manual mode where I can just set the duty cycle % and cycle time and an auto mode to set the Set Point, cycle time and PID parameters (P,I,D). I can plot real time data on the android device of the duty cycle % of the heating element, current temperature and set point and save bitmaps of the charts. I will shortly add saving raw data and alarms for reaching the set point and hops additions.

I use an ice cream maker motor controlled by a router controller and a stainless steel drywall mixer to keep the water agitated while measuring the temperature. This will ensure I get a proper temperature measurement. I fit the lid of a 10 gallon cooler over aluminum sheathing that I cut to fit the top of the keg. The ice cream maker motor also does double duty in the cooler in order to mix the grain while mashing.

I also made a stainless steel stand that the immersion chiller to sit on over the heating element using eyebolts and a stainless steel splatter screen.

Maybe eventually I will add pumps, but for now I will use buckets to collect the runnings and then gravity feed it into the keggle.

The best location I have to brew is in the basement. I wanted to shorten the brew day waiting for the water to heat up and stop using propane which forces me to lug equipment up and down the cellar steps in order to do it safely. I also wanted to be able to do 10 gallon batches in a limited space while not spending a lot of money. I had a free dryer outlet since we moved the washer and dryer upstairs, so I thought I'd set up an inexpensive electric system. I really liked the panels I see on this board but I'm better with software. Therefore, I created an android app that controls a 220V, 5500 watt heating element in a 15.5 gallon vessel via an Ethernet bridge (a router with custom firmware) and I have a one wire digital sensor in a probe for receiving temperature data. An embedded processor uses a PID algorithm to set to the desired temperature. It has a manual mode where I can just set the duty cycle % and cycle time and an auto mode to set the Set Point, cycle time and PID parameters (P,I,D). I can plot real time data on the android device of the duty cycle % of the heating element, current temperature and set point and save bitmaps of the charts. I will shortly add saving raw data and alarms for reaching the set point and hops additions.

I use an ice cream maker motor controlled by a router controller and a stainless steel drywall mixer to keep the water agitated while measuring the temperature. This will ensure I get a proper temperature measurement. I fit the lid of a 10 gallon cooler over aluminum sheathing that I cut to fit the top of the keg. The ice cream maker motor also does double duty in the cooler in order to mix the grain while mashing.

I also made a stainless steel stand that the immersion chiller to sit on over the heating element using eyebolts and a stainless steel splatter screen.

Maybe eventually I will add pumps, but for now I will use buckets to collect the runnings and then gravity feed it into the keggle.