_Edge

Well-Known Member

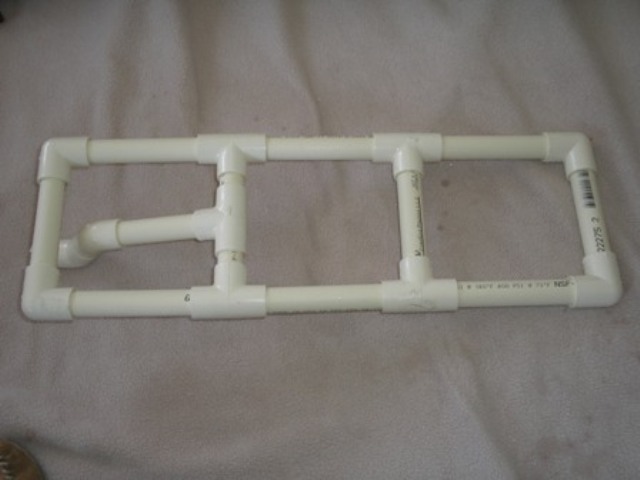

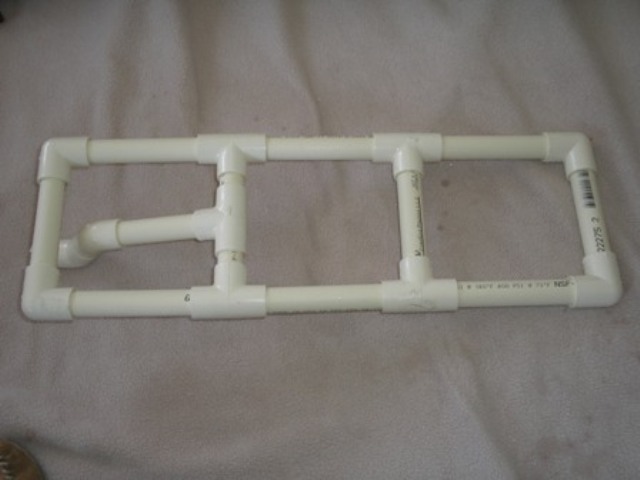

I thought I would post my MLT cooler conversion because I haven't seen anyone do it exactly like this. This is my first and I want to know if I should expect any problems on brew day.

Also, since I'm taking the time, I thought I would post exact specifics so that folks could go to the store and cut things themselves without doing annoying CPVC calculations (as I had to do). If you have this cooler, you should be able to go out and buy what I did and put it together in just a couple of hours.

I should note first that the idea is from here and here, but with CPVC instead of copper. There are a few differences. First, I left more space at the end of the cooler -- I think the physics palmer writes about works at that end too. Second the CPVC is a little closer on the long side. this is mostly a function of the CPVC attachments.

Shopping list:

• CPVC lengths of 3/4" diameter (less than 5 feet total) cut into lengths of:

o 6x 5 ¼”

o 3x 4 5/8”

o 2x 1 7/8”

o 1x 4 1/8” (this may vary)

o 1x 1 ½”

• 4 CPVC 90 degree joints

• 5 CPVC T joints

• 2 CPVC 45 angle joints

• 1 female threaded to non-threaded CPVC adapter (I had to use 1/2 inch for this adapter because that's what threads into the 1/2 inch nipple. You may need to wrap heat resistant tape around it to get a snug fit)

• 5 ¾ inside diameter (ID) x2” outside diameter (OD) zinc fender washers

• 1 ¾ ID x 1" OD SS (or other hot water-safe) washer

• 2 rubber 5/16” ID 2" OD washers

• 1 2 1/2" brass pipe nipple

• 1 1/2" brass ball valve

• 1 1/2" hose barb adapter

• teflon tape

• 1 ¾” ID 1” OD Rubber washer saved from the cooler

Total bill: $25 with some extras included in case I screwed up (which I did)

The assembly is pretty simple.

1) remove the original plastic stop valve. they normally screw out. Save the rubber washer for re-use.

2) assemble the nipple and ball valve. You will need between 3 and 6 washers as spacers so that the seal is tight enough that water does not leak out. The rubber washers should be put in from left to right (see picture), this will ensure the rubber seals to the cooler. Also, make sure to wrap the threads with teflon tape to prevent leaks.

3) cut the CPVC to the specified lengths.

4) drill holes in the PVC with about a 1/8 drill. Remember that the last 7/8 of an inch on both sides of the CPVC are going to be attached to the joints so don't drill there. Also even the smallest CPVC length should be drilled so you you can extract wort from the dead space -- it is long enough by about 1/8 of an inch for drill space.

Also, since I'm taking the time, I thought I would post exact specifics so that folks could go to the store and cut things themselves without doing annoying CPVC calculations (as I had to do). If you have this cooler, you should be able to go out and buy what I did and put it together in just a couple of hours.

I should note first that the idea is from here and here, but with CPVC instead of copper. There are a few differences. First, I left more space at the end of the cooler -- I think the physics palmer writes about works at that end too. Second the CPVC is a little closer on the long side. this is mostly a function of the CPVC attachments.

Shopping list:

• CPVC lengths of 3/4" diameter (less than 5 feet total) cut into lengths of:

o 6x 5 ¼”

o 3x 4 5/8”

o 2x 1 7/8”

o 1x 4 1/8” (this may vary)

o 1x 1 ½”

• 4 CPVC 90 degree joints

• 5 CPVC T joints

• 2 CPVC 45 angle joints

• 1 female threaded to non-threaded CPVC adapter (I had to use 1/2 inch for this adapter because that's what threads into the 1/2 inch nipple. You may need to wrap heat resistant tape around it to get a snug fit)

• 5 ¾ inside diameter (ID) x2” outside diameter (OD) zinc fender washers

• 1 ¾ ID x 1" OD SS (or other hot water-safe) washer

• 2 rubber 5/16” ID 2" OD washers

• 1 2 1/2" brass pipe nipple

• 1 1/2" brass ball valve

• 1 1/2" hose barb adapter

• teflon tape

• 1 ¾” ID 1” OD Rubber washer saved from the cooler

Total bill: $25 with some extras included in case I screwed up (which I did)

The assembly is pretty simple.

1) remove the original plastic stop valve. they normally screw out. Save the rubber washer for re-use.

2) assemble the nipple and ball valve. You will need between 3 and 6 washers as spacers so that the seal is tight enough that water does not leak out. The rubber washers should be put in from left to right (see picture), this will ensure the rubber seals to the cooler. Also, make sure to wrap the threads with teflon tape to prevent leaks.

3) cut the CPVC to the specified lengths.

4) drill holes in the PVC with about a 1/8 drill. Remember that the last 7/8 of an inch on both sides of the CPVC are going to be attached to the joints so don't drill there. Also even the smallest CPVC length should be drilled so you you can extract wort from the dead space -- it is long enough by about 1/8 of an inch for drill space.