This is probably too many posts in a row now, at 3, but whatever.

AlphaOmega, a quick temp calibration observation, and some suggestions about the software.

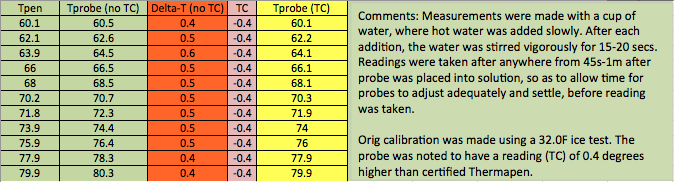

First off, after calibrating to 32.0F ice water, I decided to do some with a cup of 65.1F water. The probe read 65.4F, which is of course 0.3F high. So there's definitely some tweaking still necessary, most likely. However, this brings up a valid question --- how much tweaking is possible/necessary to attempt before you can never truly get an accurate look-up table. And furthermore, how much of it is likely due to manufacturing variances from probe to probe. This isn't an industrial/commercial-grade probe after all, and costs pennies to make.

For all of you other guys who've flashed, please calibrate to 32.0F water, then do a test in the 60-70F range and see what kind of differences you get! This data is very useful. I may go back and do some more thorough testing in the 60-75F range, attempting to test every 2 degrees and comparing (ie. 60, 62, 64, 66, 68, etc).

Now, onto the menu suggestions:

1. Why is the Profile accessible through both the main menu, as well as the Set menu? This seems repetitive, and possibly confusing.

2. Based on #1, why not have the "Run" function located on the main menu instead of having it inside the "Set" menu?

So basically, the main menu would contain:

1. Run -- choose to then find a profile to execute. However, don't have settings on the Profiles when you choose. So basically, I'd press S to bring up the main menu, then choose "rn", then choose Pr0, for example, and it's done. No settings to bring up, etc. Just a very quick and to-the-point execution of a profile.

2. Set -- show all settings, but also show profiles. Or perhaps, somehow have the profiles as a submenu inside the Set menu. But bottomline, keep the settings of setpoints and durations for profiles somewhere inside the "set" menu, and nowhere else.

Thoughts?