First of all, big thanks to Yooper. She took the time to go back and update all of my previous posts with the updated image URLs. Thanks Yooper!

Second, I'd like to let everyone know that after about 6 or 7 batches the JB Stik connecting the element to the electrical box ended up failing. I ended up noticing it while getting ready for a brew session. I always give everything a once-over and noticed that the electrical box was a little loose. Upon closer inspection, the JB Stik had separated from the box. This is why I purposely ended up using silicone caulking to seal off the connections. To fix it, I ended up removing all of the old JB Stik (just had to chip it away) and the silicone caulk around the base. I then sanded down the back of the box some more and used original JB Weld to bond the base of the element to the box. Once cured, I then went over top of that with the silicone caulk to ensure a watertight seal. It seems quite a bit more solid, and hopefully it'll hold up this time. Sorry, I didn't snap any pics of this.

Finally, I have some pictures of some recent additions/modifications that I've made over the past few days.

I finally ended up picking up a March Pump so that I can recirculate during the mash and chilling stages of the brew day. Even with the reflectix insulation, I was experiencing some temp drop off during my mash. When the element would kick on, it would generally then heat up a bit too much and overshoot my mash temp unless I was stirring as it was heating. Since I have a side pickup tube, I'm also hoping that doing a whirlpool while chilling will help me eliminate some of the break/hop particulate from entering the fermenter (and also decrease chilling time).

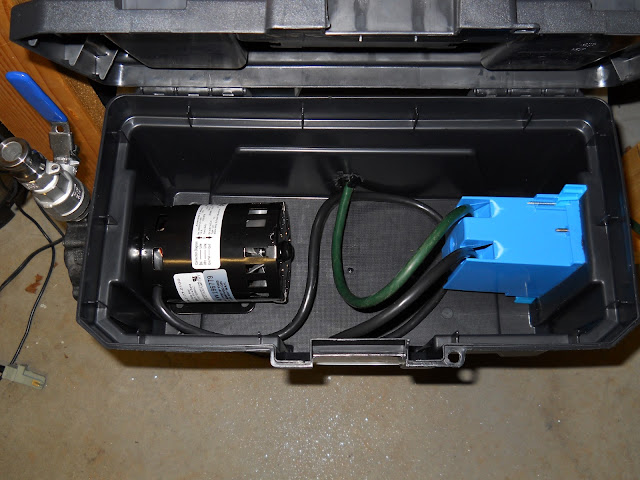

Since I plan on placing my pump directly below my kettle, I ended up going with a simple $6.99 toolbox enclosure.

I ended up buying the whirlpool fitting from bargainfittings.com and installing it. A while back I ended up buying this

el cheapo low RPM, high torque drill from Harbor Freight. I drilled out the hole with a step bit and I cannot believe how easy it was. Previously I used a cheap single-speed Black and Decker drill (so I didn't burn up my nice Makita cordless) and it was a miserable experience drilling out the holes. What a huge difference! A little bit of cutting oil and it sliced through that keg like butter.

Since I normally only do 5 gallon boils, I ended up mounting the whirlpool/recirculation fitting down low, at the same level as my pickup. I know this should work fine for the whirlpool, and I'm really hoping it will work ok during the mash as well.

Finally, here's a look at the whole setup. Since I plan on recirculating during the mash, I ditched the refletix for now. It made things a little more difficult to clean, so if it doesn't provide me any benefit I'd just assume leave it off.