Photopilot

Well-Known Member

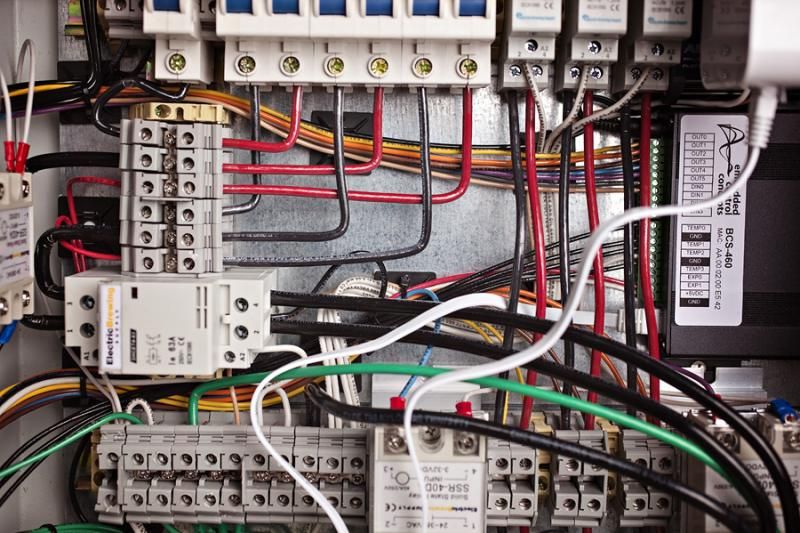

It is still a work in progress. So far it is only running my BK. It had its maiden voyage last weekend. Hope to tweak it with a HLT element this coming weekend.

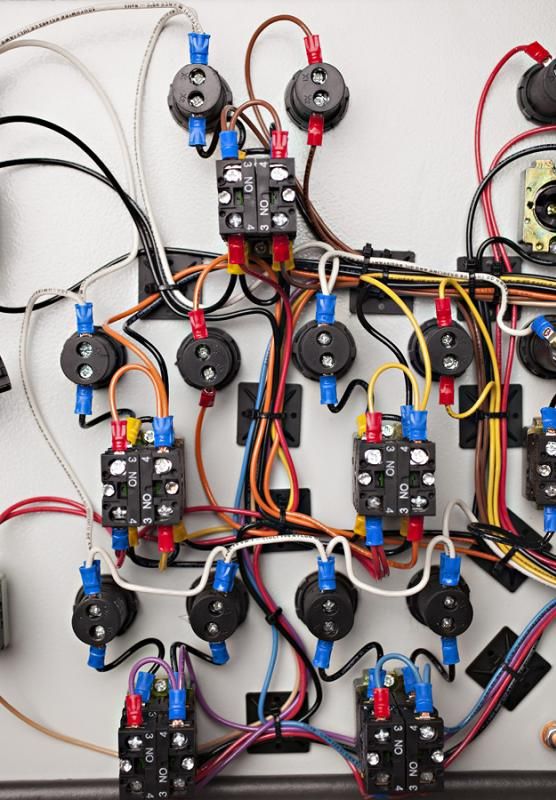

Yes, you can change the settings in the PID to change the alarm condition. Not quite as quick/convenient since 99% of the time the alarm is there to tell you that you need to "do something" so the last thing you want to do first is hit a dozen or so buttons in the PID to reprogram what causes an alarm. Normally I just switch off the alarm with one flick, and then do whatever needs to be done. The switches are only a few dollars each and (IMHO) are worth it to make the process easier.Hey Kal, is there a way to turn the PID alarms on and off without external switches?

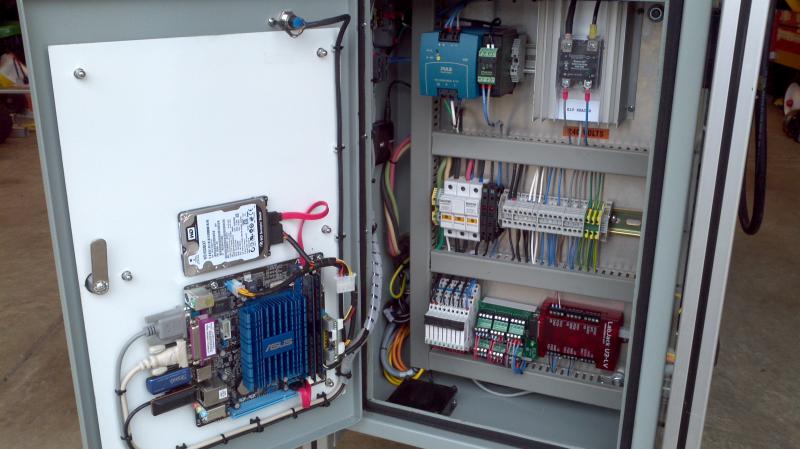

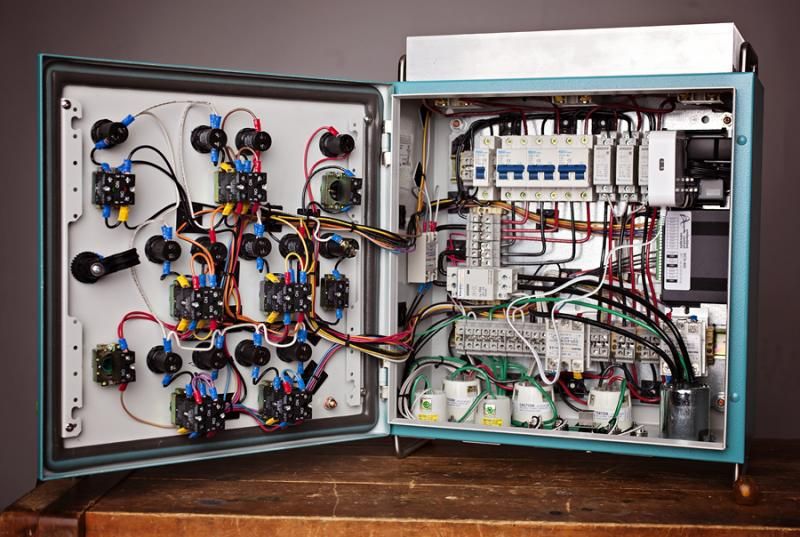

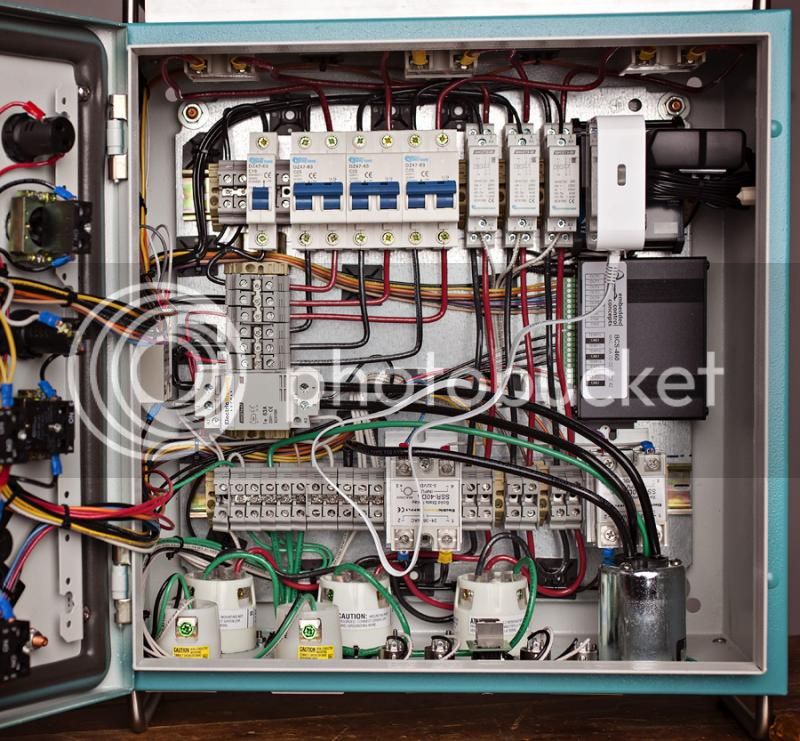

That has to be about the best designed and constructed control panel I have seen here in a long time, it looks like it came from a professional panel shop .

It is nice to see someone design and build a control panel that is not an illustration of code violations and bad practices like some of the ones offered for sale that I have seen.

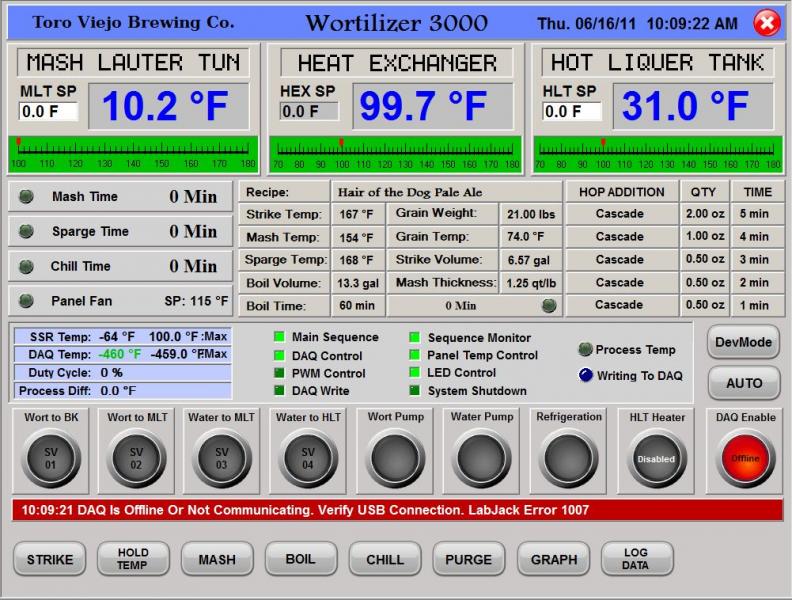

Is the software package you are using the Lab Jack offering or is it something you have created in VB to work with the touch screen monitor shown.

What do I win for having the pimpin'-ist, most awesome control panel EVER?

Enter your email address to join: