I have my 240v 30 amp power in my brew area now. But I need a cheap electrical brew system to use while I build something more permanent. I thought that a single PID 5500 watt system would be cheap, but I am at around $300 in parts, and about $200 in tools to build that. Anyone have a simple, low cost, single kettle system to get me brewing?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I need a cheap, single kettle system

- Thread starter GRHunter

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

wyzazz

Well-Known Member

How many gallons are you going to be brewing? Extract/PM/AG? You can do a BIAB electric rig with a single 3000/4500/5500W heatstick to get you started. You won't have precise temp control without the PID but you will certainly be able to brew. Just fire up the heatstick to maintain temps during the mash.

I've found that 3000W will boil a 6gal batch with no issues and give me a good boil off, my preboil volume is 7.5gals in a keggle.

I've found that 3000W will boil a 6gal batch with no issues and give me a good boil off, my preboil volume is 7.5gals in a keggle.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

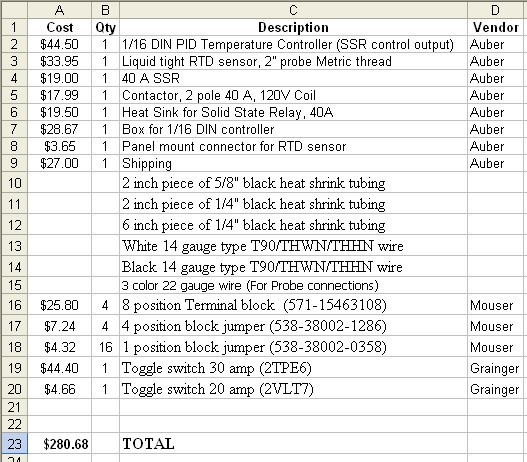

I have my 240v 30 amp power in my brew area now. But I need a cheap electrical brew system to use while I build something more permanent. I thought that a single PID 5500 watt system would be cheap, but I am at around $300 in parts, and about $200 in tools to build that. Anyone have a simple, low cost, single kettle system to get me brewing?

I think anyone will tell you, building anything that is safe and you can grow into will be a little bit of an investment - it is worth it.

If you ever plan on doing 10G batches, go with the 5500W - you need it. Just curious, are you part shopping from electric brewery's site? I know some of the links on that for the parts were a little pricey, but you can find a lot of stuff on ebay or similar at a lower price. You just need to know what it is you are looking for.

Maybe post your parts list and tool list so people can comment on it. A lot of the tools you can side step (greenlees, etc.)

GRHunter

Well-Known Member

5 gallon all grain batches. I need some kind of controll to maintain a proper boil.

How many gallons are you going to be brewing? Extract/PM/AG? You can do a BIAB electric rig with a single 3000/4500/5500W heatstick to get you started. You won't have precise temp control without the PID but you will certainly be able to brew. Just fire up the heatstick to maintain temps during the mash.

I've found that 3000W will boil a 6gal batch with no issues and give me a good boil off, my preboil volume is 7.5gals in a keggle.

GRHunter

Well-Known Member

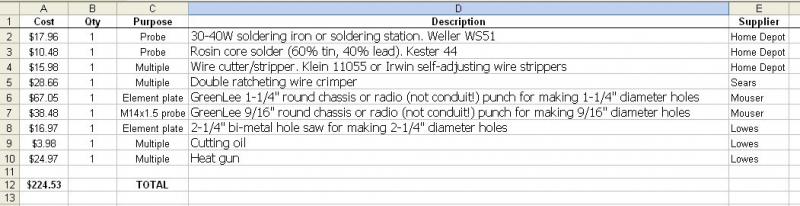

I am using a modified version of the electricbrewery design so I am using their parts list, but not all their suppliers. I am at work now, but I'll post my current list of parts. How can I sidestep the greenlee punches? They are a huge portion (about 50%) of my tool costs.

I think anyone will tell you, building anything that is safe and you can grow into will be a little bit of an investment - it is worth it.

If you ever plan on doing 10G batches, go with the 5500W - you need it. Just curious, are you part shopping from electric brewery's site? I know some of the links on that for the parts were a little pricey, but you can find a lot of stuff on ebay or similar at a lower price. You just need to know what it is you are looking for.

Maybe post your parts list and tool list so people can comment on it. A lot of the tools you can side step (greenlees, etc.)

If you are starting from scratch, propane (turkey fryer/burner + tank+thermometer) is a little less than PID+SSR+Enclosure+thermocouple+powercord+30amp plug)

t

t

wyzazz

Well-Known Member

With 3000W you don't really need any control for 5gal batches. I find that I boil just fine, although the temp control would be nice for mashing. I can get from 57F to a nice rolling boil in just under 60mins.

Instead of using a greenlee punch, just use a step bit or hole saw.

Instead of using a greenlee punch, just use a step bit or hole saw.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

I am using a modified version of the electricbrewery design so I am using their parts list, but not all their suppliers. I am at work now, but I'll post my current list of parts. How can I sidestep the greenlee punches? They are a huge portion (about 50%) of my tool costs.

That is what I thought - you can omit greenleessure they are nice, but a step drill and/or hole saw will work. I used a harbor freight step drill bit to bore out a 1 1/4 inch hole in my stainless pot - perfect hole. You just get a can or plastic bottle and fill with oilt (Bobby's trick). Drill, dip the bit in the oil and swish around, drill, to cool off drill, until you get there. (see my example pics - https://www.homebrewtalk.com/f170/electric-burners-any-builders-out-there-228720/index34.html)

You can use the same technique for your control panel for the lights and switches.

A lot of the materials from the electric brewery can be substituted, (plugs at HD are way cheaper than the listed leviton plugs, etc.) The Electric brewery site is unreal, and the parts are top notch - so don't get me wrong. But if you are on a budget you can get better prices with some digging.

rico567

Well-Known Member

I have my 240v 30 amp power in my brew area now. But I need a cheap electrical brew system to use while I build something more permanent. I thought that a single PID 5500 watt system would be cheap, but I am at around $300 in parts, and about $200 in tools to build that. Anyone have a simple, low cost, single kettle system to get me brewing?

I believe that electric brewing is in my future. It would be much more convenient and less labor for me to brew electrically. But I must advise you, sir, that as far as my reading has gone (and I've pretty much exhausted this section of HBT and some things elsewhere on the net), wishing for a cheap electric brew system is like longing after the electric car that will go 400 miles, or an inexpensive family spaceship. It ain't to be had.*

* I do not define heatsticks, as normally implemented, as true electric brewing. I mean an element or elements fixed in a pot, with effective temperature controls, and the ability to mash and boil in the same pot. "Brew sculptures" have few charms for me, and I have neither the space for them nor the inclination to deal with their cost or complexity.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

http://cgi.ebay.com/Solid-State-Rel...377?pt=LH_DefaultDomain_0&hash=item2559d411d9

$15 vs $~40

No need for those giant switches if you are using a contactor, though not sure what you wiring is, or what the switches are for. That would knock another $30 off.

You don't need to solder - get switches with screw terminals. You only need a basic wire cutter/stripper crimper. Ditch the green lees for harbor freight step drills (IMO). That saves you ~$155

You don't really need the heat shrink or the heat gun either. Electrical tape works just fine.

I agree with Rico - it will never be cheap. However, the set it and forget it aspects are awesome. And no running for propane anymore.

I would go with an electrical element in a BK and HLT and direct fire your MT; unless you have a pump. That is what I am doing. So heat strike water in BK/HLT, the dump into MT, direct fire with propane if you lose temp during your mash. Boil in BK.

All that would save you over $200

my .02

$15 vs $~40

No need for those giant switches if you are using a contactor, though not sure what you wiring is, or what the switches are for. That would knock another $30 off.

You don't need to solder - get switches with screw terminals. You only need a basic wire cutter/stripper crimper. Ditch the green lees for harbor freight step drills (IMO). That saves you ~$155

You don't really need the heat shrink or the heat gun either. Electrical tape works just fine.

I agree with Rico - it will never be cheap. However, the set it and forget it aspects are awesome. And no running for propane anymore.

I would go with an electrical element in a BK and HLT and direct fire your MT; unless you have a pump. That is what I am doing. So heat strike water in BK/HLT, the dump into MT, direct fire with propane if you lose temp during your mash. Boil in BK.

All that would save you over $200

my .02

wyzazz

Well-Known Member

To follow up with what CidahMastah said above, you could even go simpler and not use the contactors if you are switching under 30A @ 240v. One of these is available at your local big box store. Sure it's not nearly as fancy as some of the switches you've seen here, but it does the job if you're under 30A.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

To follow up with what CidahMastah said above, you could even go simpler and not use the contactors if you are switching under 30A @ 240v. One of these is available at your local big box store. Sure it's not nearly as fancy as some of the switches you've seen here, but it does the job if you're under 30A.

And this is a "builder's choice" discussion you need to have with yourself. I went with the contactor's based on the advice from this forum from an EE I respect. The nice part about the contactor is that your switch is wired to 120V and you will never touch a switch that is juiced with 240v. In my case I also have a cheap radio shack 1 amp fuse heading into the switch; i.e. I can't ever get shocked with more than 120v at 1amp if I were to touch the switch with wet hands.

In short, I chose the contactor for safety reasons - but that is up to each builder to decide.

conpewter

Well-Known Member

Technically you don't even need the switch. Especially if you are using the cord with the built in GFCI. Either way you could always turn it off by the breaker. I would recommend the switch or contactor though. I have the 30 amp switch linked from above. I did a cheap but effective electric system a few years back. Used an old watertight ammo box for my control box. PID and 40A SSR, used a heat sink from an old computer instead of buying a new one. Used wire nuts (and 10 gauge wire) for all the connections instead of terminal blocks, they are tight and wrapped with electrical tape. I do have a HLT and BK, but I just plug them in to the control box when I want to use either one, that way I have no way to try and run both 5500W elements off a 30 amp circuit. A one vessel system would be pretty sweet too.

kal

Well-Known Member

Another option for the punches is to simply rent/borrow them. I know at least once brewer's offered his up for others to use for only the cost of shipping.

Kal

Kal

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Another option for the punches is to simply rent/borrow them. I know at least once brewer's offered his up for others to use for only the cost of shipping.

Kal

https://www.homebrewtalk.com/f170/greenlee-knockout-punch-lend-1-1-4-a-211010/

I was going to do this, but wanted to continue with my build. I borrow a neighbors greenlee's for some of the spots on my control box - if you can get them they work very well. Unfortunately my neighbor didn't ahve the 1 1/4 sized I needed for the element.

Similar threads

- Replies

- 14

- Views

- 1K