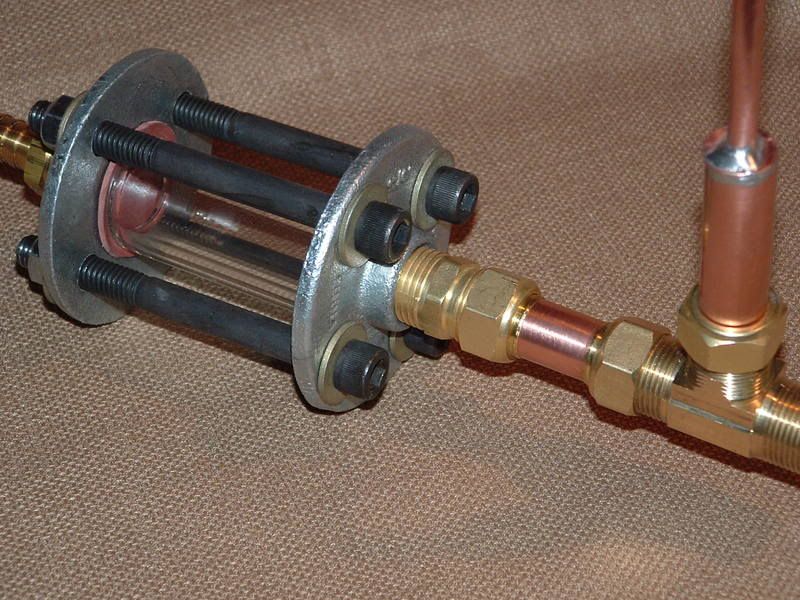

I've been wanting to do this for awhile and if I would have realized how cheap and easy it was I would have done it sooner. My injector is made from brass 1/2"FPT Tee, 1/4 compression x 1/2MPT, 3/8 compression x 1/2MPT, 5/8 compression x 1/2MPT and a .5 micron aeration stone. It all screws together and apart for easy cleaning. I had to drill out the 1/4 for the air line because it was not a bore through design and I replaced the 3/8 brass ferule with plastic so it could be removed from the chiller. The 5/8 connector is for 1/2" ID hose to go to the fermenter. I used a larger hose here so it might defoam a little on the way to the fermenter. It took longer to find the parts than to put it together. Cost was $16 plus the stone. It works with CFC's

I want to find an o2 flowmeter that will display less than the 1-15LPM of standard medical flowmeters but until I do will just have to guess.

I want to find an o2 flowmeter that will display less than the 1-15LPM of standard medical flowmeters but until I do will just have to guess.