zeth1560

New Member

- Joined

- Jan 25, 2013

- Messages

- 1

- Reaction score

- 0

I am in the early stages of planning a control panel for our HERMS system. I was hoping that someone could tell me if I am way off base with my wiring plans.

Currently our kettle and HLT are gas fired, and we use a Johnson A419 temperature controller to maintain our mash temperatures by recirculating as necessary through a heat exchanger in the HLT.

I would like to change things so that the mash recirculates constantly, and is routed through one of two solenoid valves depending upon whether it needs to be heated or not. I also plan to add a heat stick to the HLT so that we can control the temperature of our sparge water more precisely. I am also planning to add a grant to the system, which will have two float switches allowing it to turn on and off automatically depending upon the level of the wort within the receptacle.

That said, here is what I have been drawing up. Please tell me if I am way off base with any of this. I am fairly comfortable with house electrical wiring, but am a complete newbie when it comes to relays and the like.

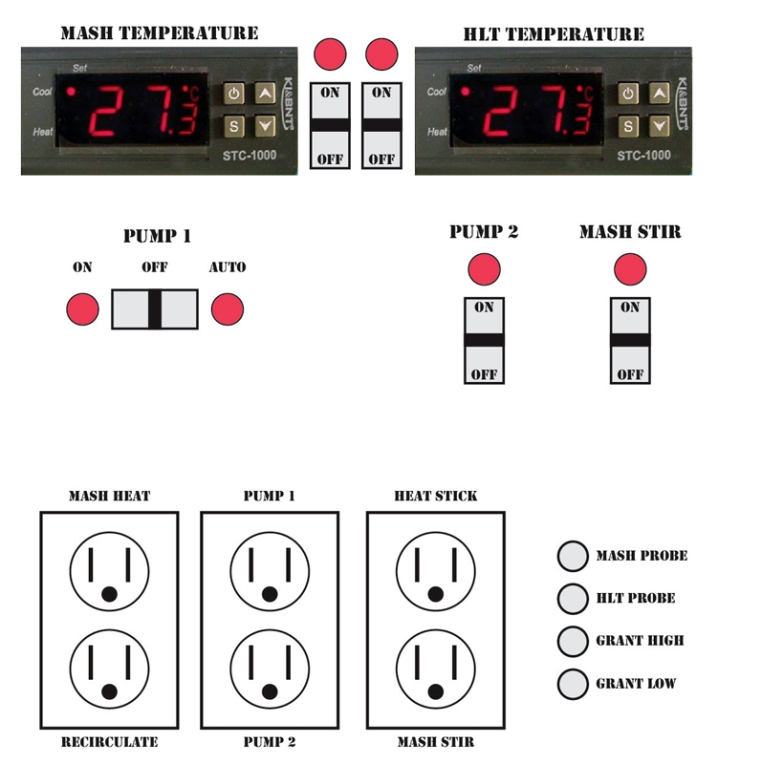

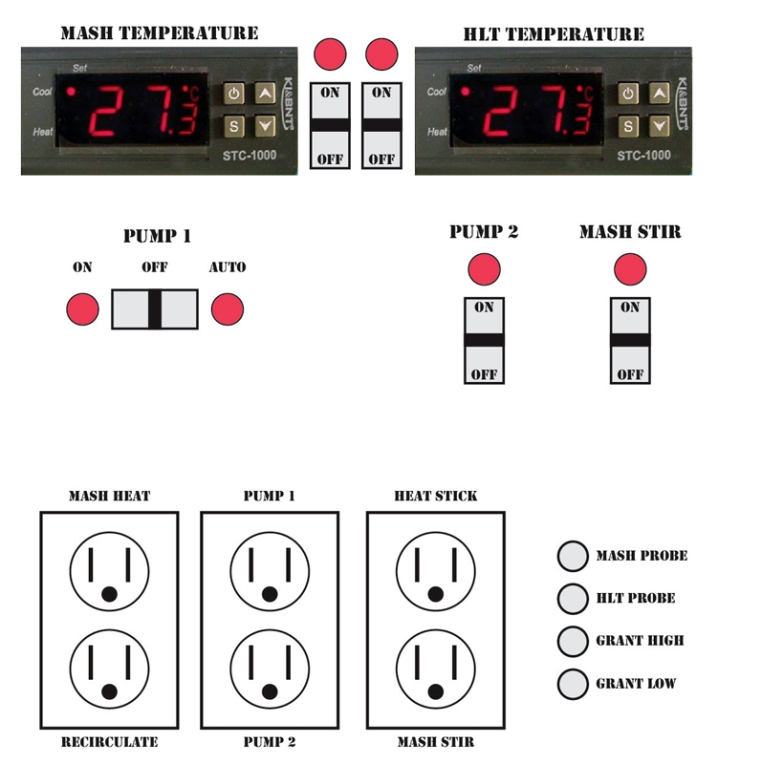

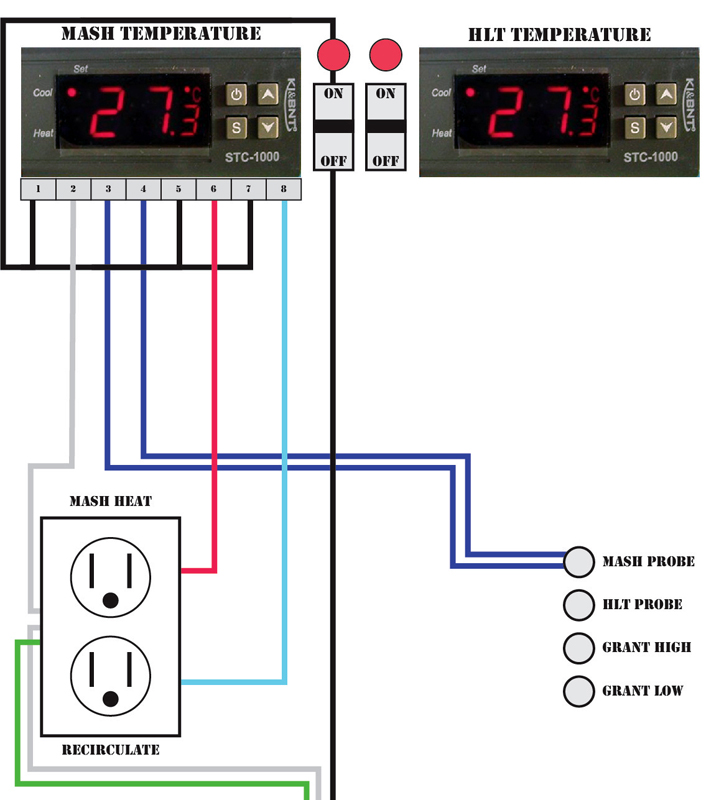

The front of the panel:

I am planning to use two of the STC-1000 temperature controllers to regulate the Mash and HLT temperatures. I also plan on having input jacks for the temperature probes and float switches. All the electrical stuff will plug into standard wall outlets at the bottom of the panel.

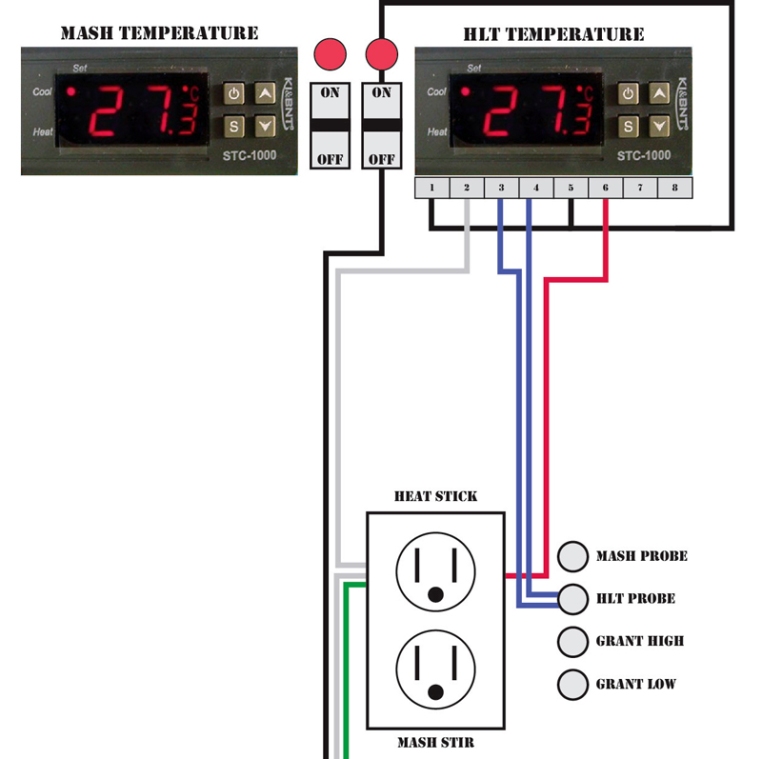

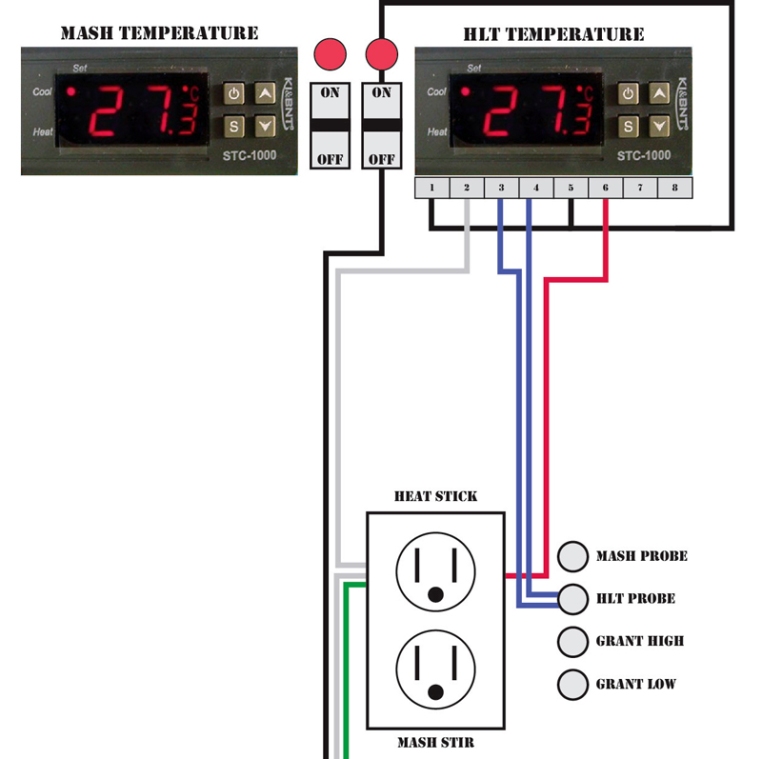

The controls and wiring for the heat stick in the HLT:

The heat stick itself will use a 1500W 120v water heater element. We will still use propane to do most of the heating, and will only use the stick to maintain the temperatures once we get there. The AC input will be pulled in from a separate circuit from the rest of the brewery, and will be GFI protected.

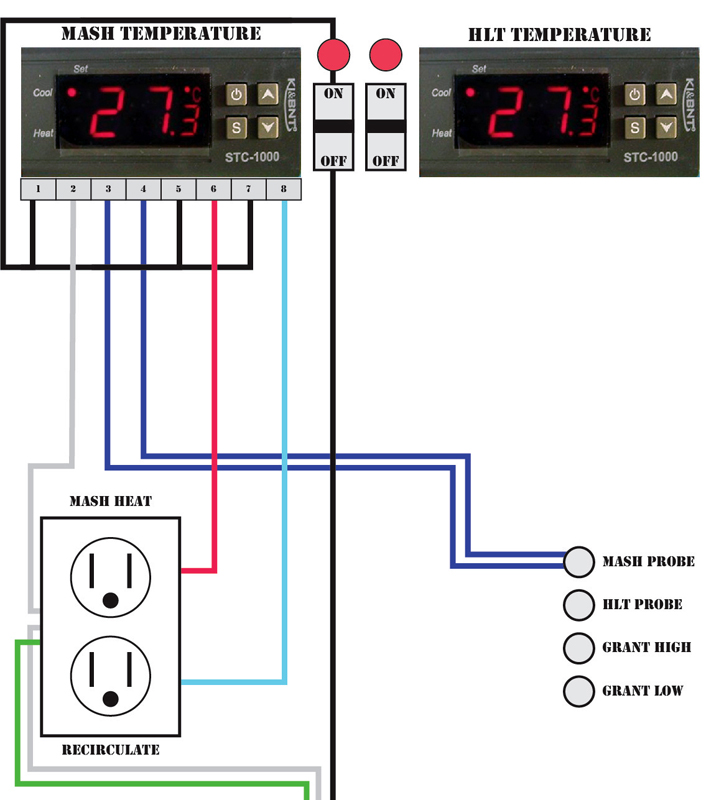

The HERMS solenoid controls:

Mash heat will activate a 110v solenoid valve that will send the wort to the heat exchanger in the HLT. Mash recirculate will open a second 110v solenoid that will send the wort back to the top of the tun.

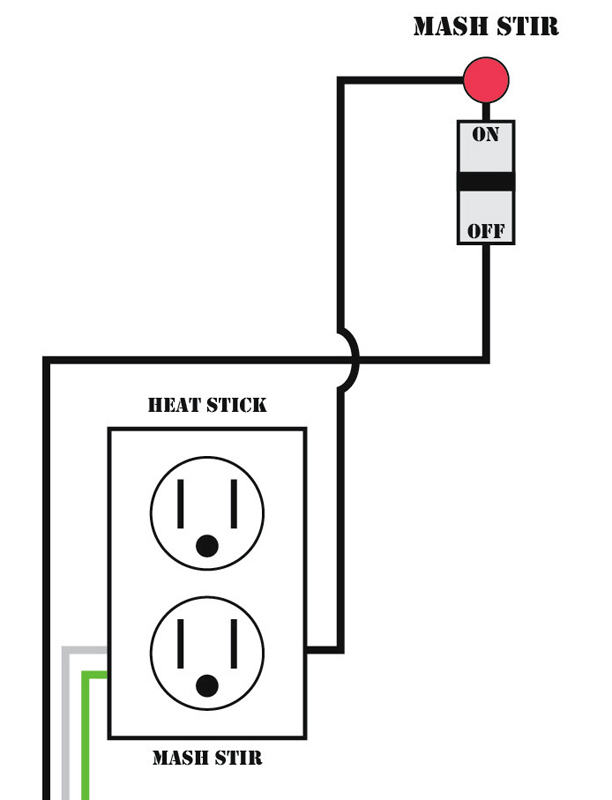

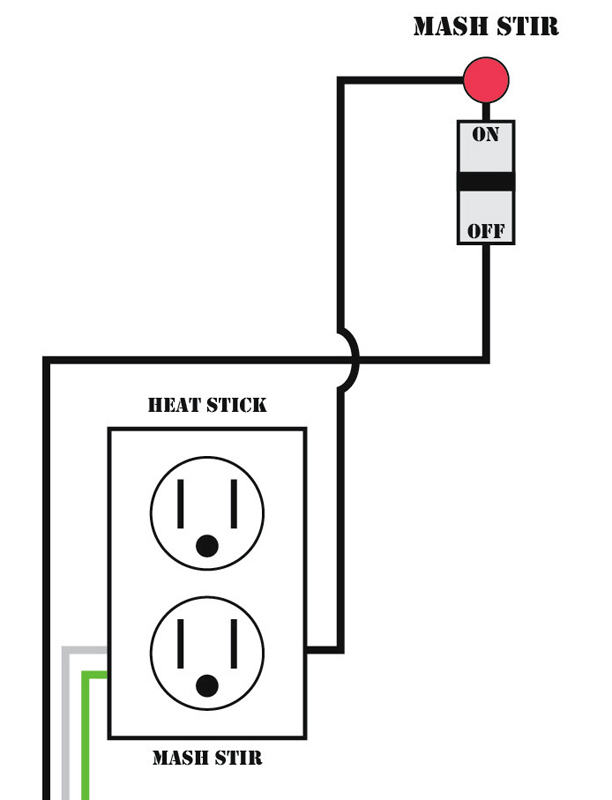

Mash Stir:

This will turn our mash agitator powered by a low rev, high torque motor. Most likely an ice cream maker or a rotisserie motor.

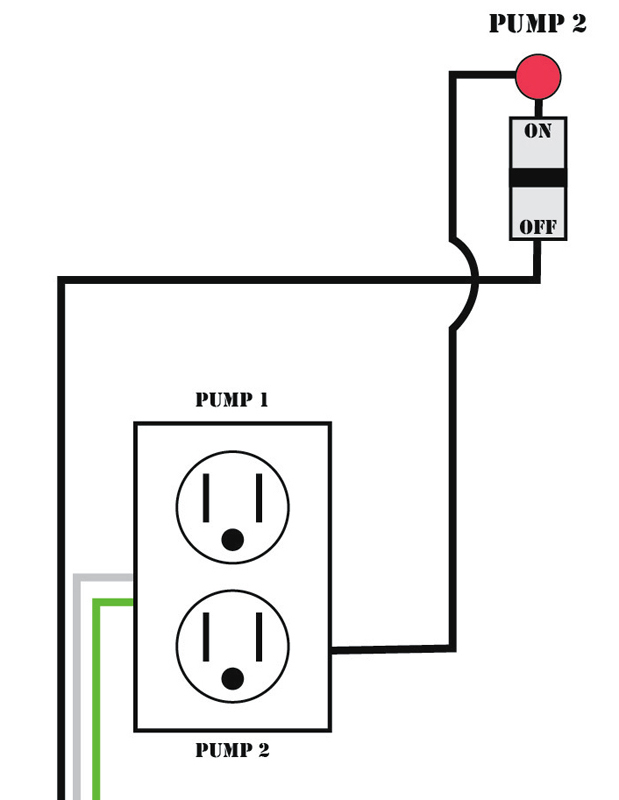

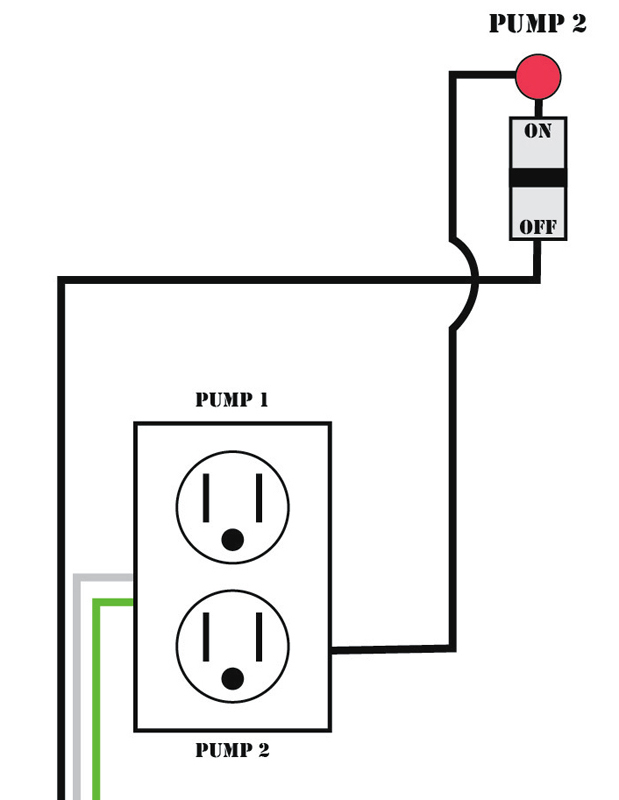

Pump 2 controls:

This will activate our submersible pump that we use with our CFC.

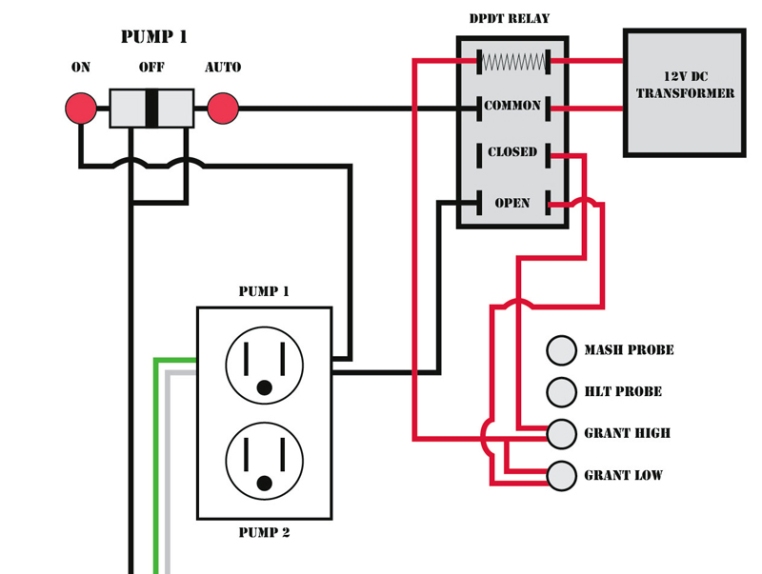

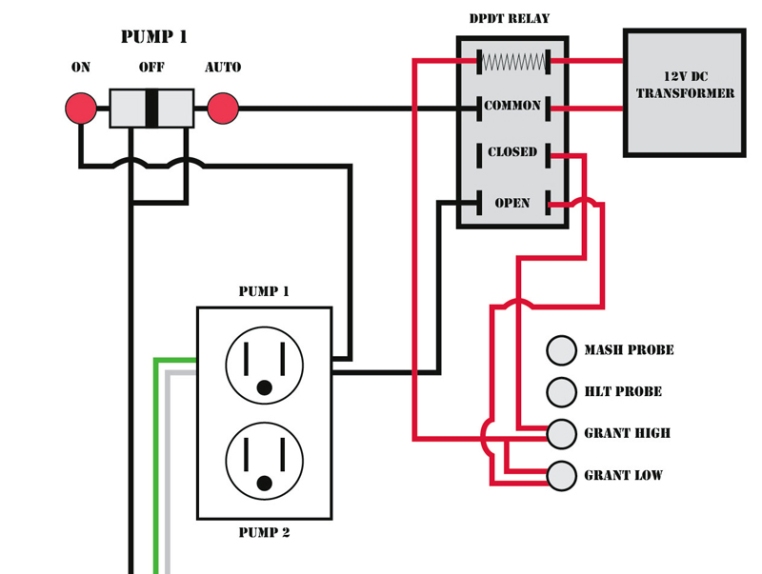

Pump 1 Controls:

This is the part that I am very much unsure about. I would like to use two float switches in our lauter grant to make sure that the pump only switches on when the wort level reaches a certain point and turns off before it sucks the grant dry. I have been scouring the interwebs for days trying to determine the best way to do this using a DPDT relay. Please take a look and tell me if any of this makes sense, and if it would work at all. Any recommendations would be greatly appreciated.

Thanks in advance for any feedback!

Currently our kettle and HLT are gas fired, and we use a Johnson A419 temperature controller to maintain our mash temperatures by recirculating as necessary through a heat exchanger in the HLT.

I would like to change things so that the mash recirculates constantly, and is routed through one of two solenoid valves depending upon whether it needs to be heated or not. I also plan to add a heat stick to the HLT so that we can control the temperature of our sparge water more precisely. I am also planning to add a grant to the system, which will have two float switches allowing it to turn on and off automatically depending upon the level of the wort within the receptacle.

That said, here is what I have been drawing up. Please tell me if I am way off base with any of this. I am fairly comfortable with house electrical wiring, but am a complete newbie when it comes to relays and the like.

The front of the panel:

I am planning to use two of the STC-1000 temperature controllers to regulate the Mash and HLT temperatures. I also plan on having input jacks for the temperature probes and float switches. All the electrical stuff will plug into standard wall outlets at the bottom of the panel.

The controls and wiring for the heat stick in the HLT:

The heat stick itself will use a 1500W 120v water heater element. We will still use propane to do most of the heating, and will only use the stick to maintain the temperatures once we get there. The AC input will be pulled in from a separate circuit from the rest of the brewery, and will be GFI protected.

The HERMS solenoid controls:

Mash heat will activate a 110v solenoid valve that will send the wort to the heat exchanger in the HLT. Mash recirculate will open a second 110v solenoid that will send the wort back to the top of the tun.

Mash Stir:

This will turn our mash agitator powered by a low rev, high torque motor. Most likely an ice cream maker or a rotisserie motor.

Pump 2 controls:

This will activate our submersible pump that we use with our CFC.

Pump 1 Controls:

This is the part that I am very much unsure about. I would like to use two float switches in our lauter grant to make sure that the pump only switches on when the wort level reaches a certain point and turns off before it sucks the grant dry. I have been scouring the interwebs for days trying to determine the best way to do this using a DPDT relay. Please take a look and tell me if any of this makes sense, and if it would work at all. Any recommendations would be greatly appreciated.

Thanks in advance for any feedback!