Okay, so I jumped the gun and bought pulleys that I found at Northern Tool, but they weren't rope specific pulleys. They had a pretty deep "V" shape, but it supported the sides of the tubing, so I figured that would work well enough. After the first 5 or 6 passes, yes, it made the diameter slightly smaller, however the tubing was starting to take the "V" shape to the extreme. Almost decided to turn my own dies on my lathe, but thought that might take a while.

Second attempt I took apart everything and wound some string around each of the pulleys, I did not measure any of this, I was only trying to fill in the gap. If I had to guess, maybe 5 to 8 feet of string? I wrapped electrical tape around the string very tightly to keep it in place and make it smooth. I then took a scrap piece of 1/2" ID, 5/8" OD copper, probably 3 or 4 feet in length to test this out before risking my coil. We got that to about a 15" semi-circle in a few passes and it looked great, so back at it with the SS coil.

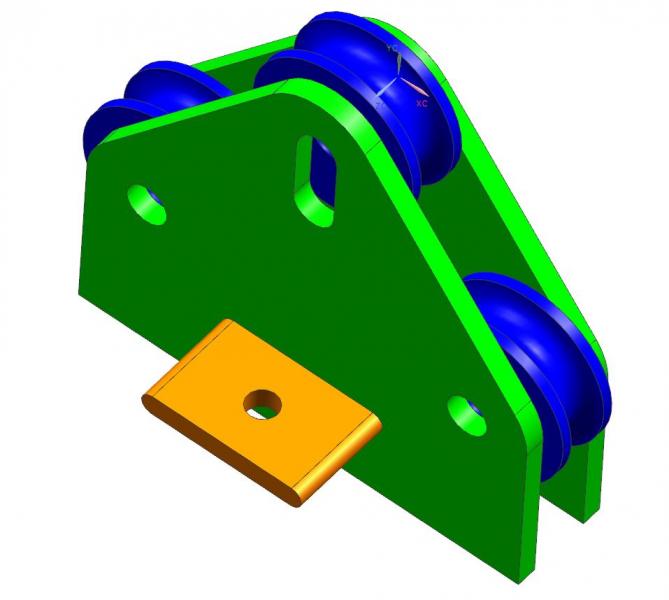

Worked awesome! Had to make a few adjustments mid-recoil, mainly because I didn't follow anyone's plans exactly, I understood the concept and just went with it. Needed to cut my adjustable bolt twice (knuckles were getting awfully close) and just like V-Twin, I eventually had to move the top structural bolts inwards and cut off the corners. As you will see I wasn't too interested in it looking very fancy (I'm not that great with a sawsall!) but did the trick beautifully! Thanks for everyone's input/help on here!