redbrewsathome

Active Member

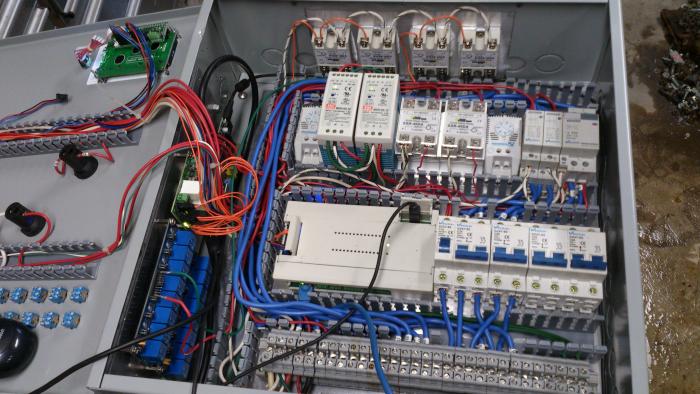

Here's some pics (poor phone pics!!) of my build so far lots of extras to finish but got the basics for brew day going!! have a couple fittings to change( don't like the quality!) but will be brewing this week, wet runs went smoothly.

Also not many pics of the beginning as I wasn't taking them till it looked like something!

Also not many pics of the beginning as I wasn't taking them till it looked like something!