Boerderij_Kabouter

Well-Known Member

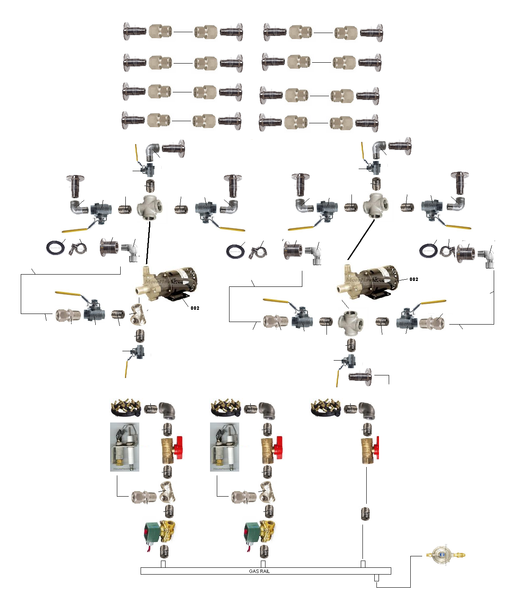

WOW!!! That is awesome! I want to see more pics

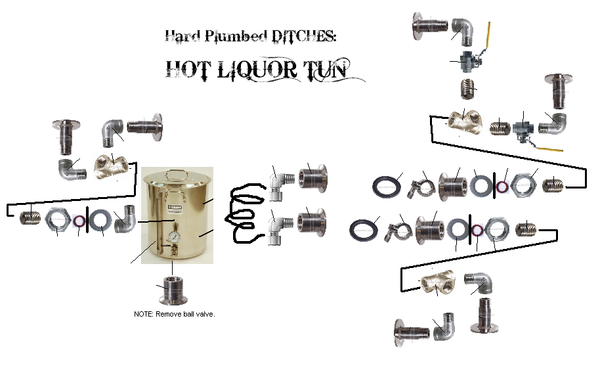

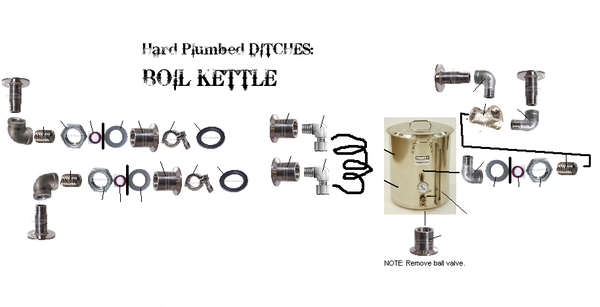

That thing is unreal! I want to see some detail shots and hear about any tweaks you made to the design.

Great work!

That thing is unreal! I want to see some detail shots and hear about any tweaks you made to the design.

Great work!