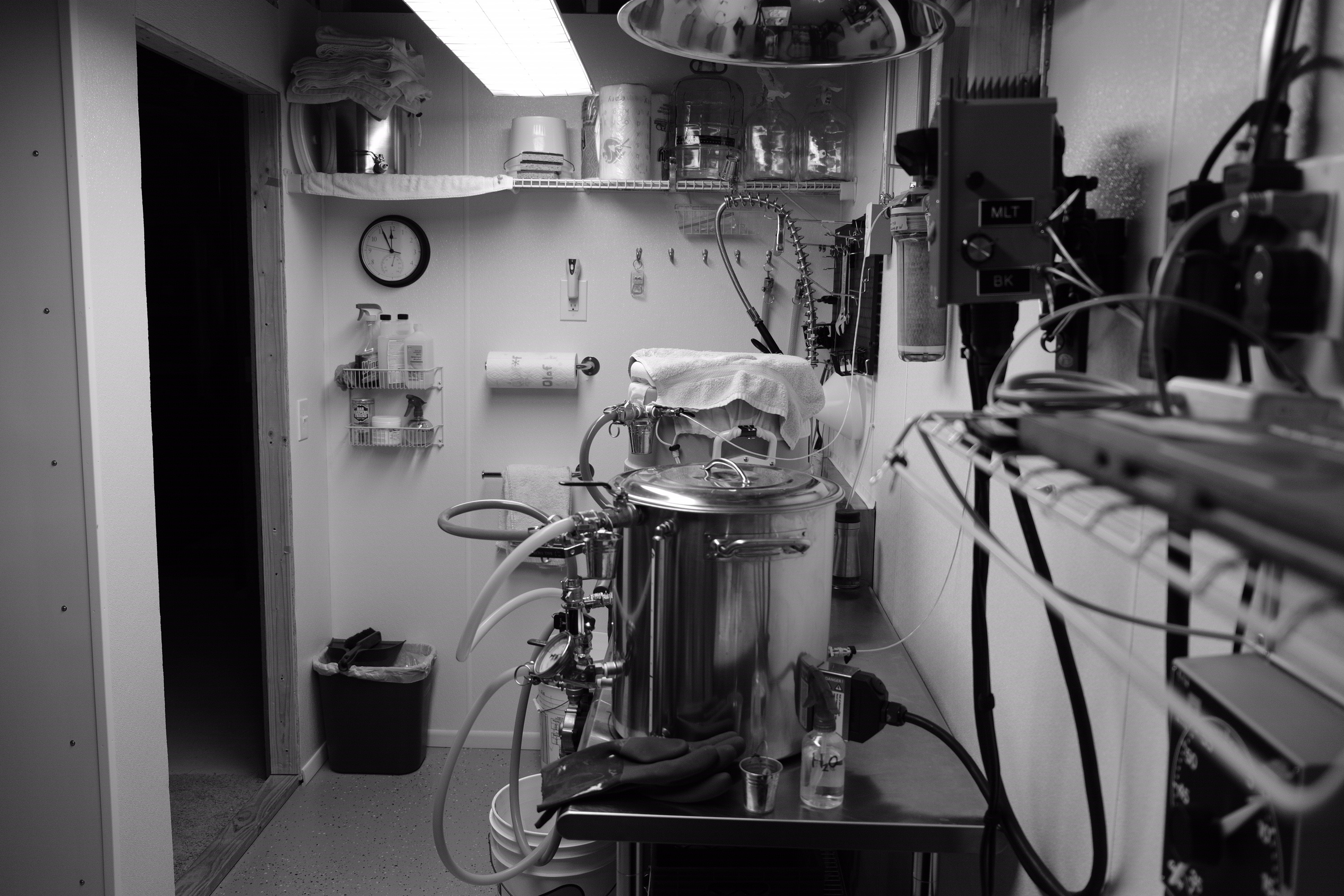

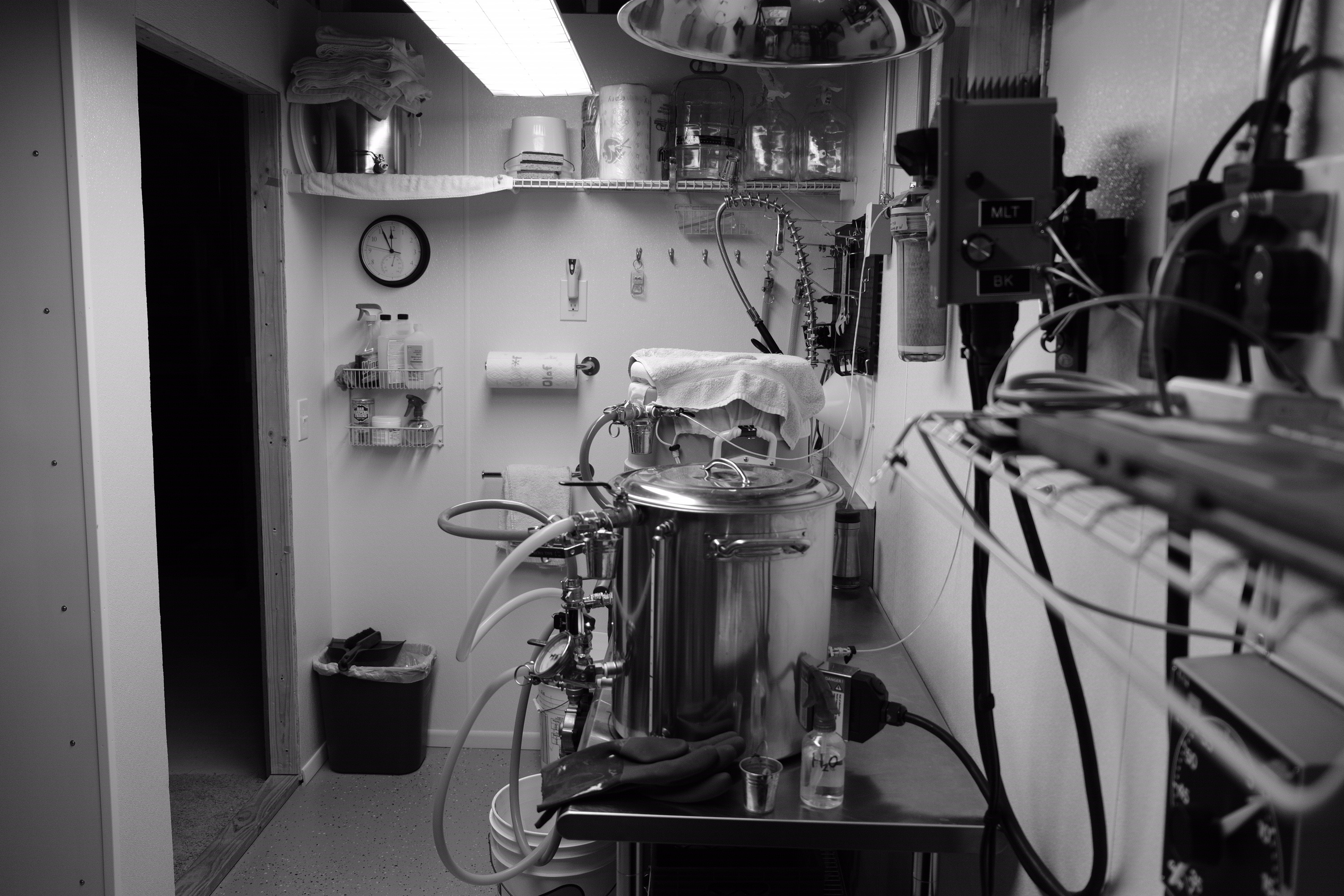

Beautiful systems - here's my setup.

Sorry for the awful mess, too many hobbies. Here's a quick look at The Brew Shed. On the left is the brew rig, fermentation happens in the middle, and then conditioning and serving happens on the right.

-the whole place-

The brew rig consists of a 30 gallon Hot Liquor Tank and two converted kegs for mash tun and boil kettle. This is configured as a Heat Exchange Recirculated Mash System.

The brain of the brew system is a BrewTroller which allows for automated temperature control of each brewing vessel. The brain manages control circuits connected to relays to engage two 240v circuits for heating elements and four 120v circuits for things like pumps, grain hoppers and so forth. It also has a web server running on it so you can control the brew process from a PC, tablet or even create your own monitoring system which queries the API.

The HLT has two 6500W elements in it as well as a copper HERMS coil. There is a selector on the brew system to allow me to fire one or both of the elements when the HLT temperature goes below the target. During the pre-heat phase, both elements are turned on in the HLT, and a pump recirculates the hot water to ensure even heating.

I put a selector on the brew system to enable both elements to fire at the HLT's temperature request, or have one enabled for HLT control and the other for Boil Kettle heating. During the mash or boil, only one element in the HLT is needed to maintain temperatures.

The Mash Tun has a stainless steel false bottom to separate grain from wort. To control mash temperature, there are a few options.

-You can set the HLT temperature to match the target mash temperature and constantly recirculate the wort for the entire mash duration

-You can set the mash pump to only recirculate wort through the heat exchanger when the mash temperature drops below the target mash temperature. This is essentially auto-temperature control on a standard infusion mash.

-You can step-mash, where your mash temperature is variable over the mash duration and will automatically advance after the set number of minutes.

The boil kettle has a 5500W ultra low watt density element and a smaller false bottom to help contain hop particles and what not.

It may be difficult to see in the picture, but there is a counter-flow chiller on the left side with an inline oxygenation system. I transfer the boiling wort directly to the fermenter and oxygenate at the same time. There is a valve on the outlet to make sure no liquid back-flows to the oxygen regulator.

-four fermentation chambers with tablet display before stain was applied-

Fermentation occurs in the four mini-fridge sized boxes in the center of the image. Wort is pumped through the chiller into the fermentation vessel, yeast is pitched and the resulting bubbling goodness sits in a temperature controlled environment until the yeast is done working. I found used mini-fridges and added heaters to make temperature controlled environments for each batch of beer I brew. The brain of the fermentation system is a Brewery Control System (BCS-460) which monitors the temperature of each chamber and can turn on the mini fridge to lower temperature, or turn on a small heater to raise temperature in each chamber independently.

-kegorater with tap list-

-broken tools and extra hardware as tap handles-

Conditioning and serving takes place in a converted chest freezer. Once fermentation has completed, the mini fridges are set to lager for whatever amount of time is desired. When the majority of yeast and trub has settled, beer is transferred to corny kegs and moved to the kegorater where they are carbonated and ready to serve.

The kegorater has one nitro tap and eight standard taps for a maximum of 9 beers on draft at any time. I often re-use broken tools as tap handles. The kegorater follows the standard design, collar on top of the chest freezer and STC-1000 temperature controller. There is a pair of manifolds with valves to distribute the CO2 to the kegs.

The tap-list display is a pretty neat project as well. It's an old TV I had sitting around the basement that we never really watch any more. I connected a chrome cast to it, and can stream videos or web pages to the TV from the shop computer. I'm also playing around with the idea of using a mini-pc or raspberry pi for display, but that hasn't been finalized yet. The short explanation here is my beersmith data files are consumed by a web application that generates the tap list on the fly based on the data entered in beersmith. All I have to do is update the web server with the XML file and the webpage is automatically updated with what's on tap.

If you made it this far, thanks for taking the digital tour of the brew shed! Feel free to message me with questions or comments!