OMJ

Well-Known Member

I think the biab one seems tedious and while it would be easier for someone who is new to brewing after a few brews they would probably want the 3 vessel setup.

Have you done any 10g BIAB bakins? Any progress/design on your dedicated rig?

Here is a little rundown:

1.059 OG

10 gallons to the fermentor

20 pounds of malt

75% eff

You need 15 gallons of water for BIAB, PLUS your 20 pounds of malt. You will easily be looking at a 20 gallon pot to be safe and have wiggle room here.

Hope this adds some value to the discussion.

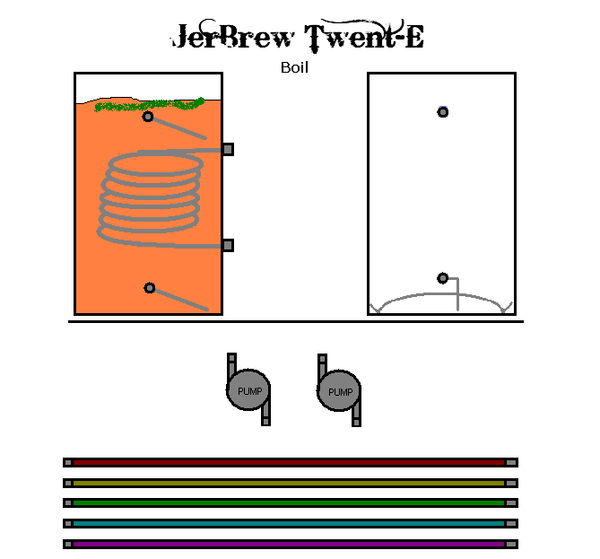

Hmmm.... I designed it with a 20.5g kettle, but I should be able to stretch the volume with my partial sparge idea where I transfer the sparge water into the fermenter then sparge the grains while partially lifter out of the kettle. This step is why I would need to have a dedicated stand.

I didn't read every post in detail but I get the basic idea of what you're trying to do. Compact 10 gallon batches. Some ideas.

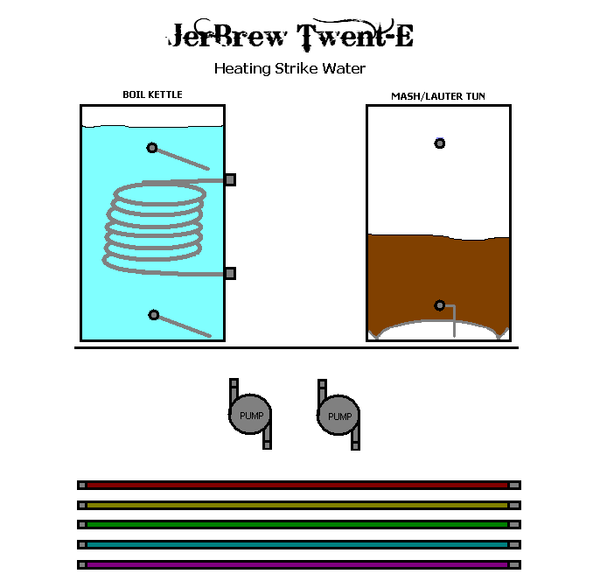

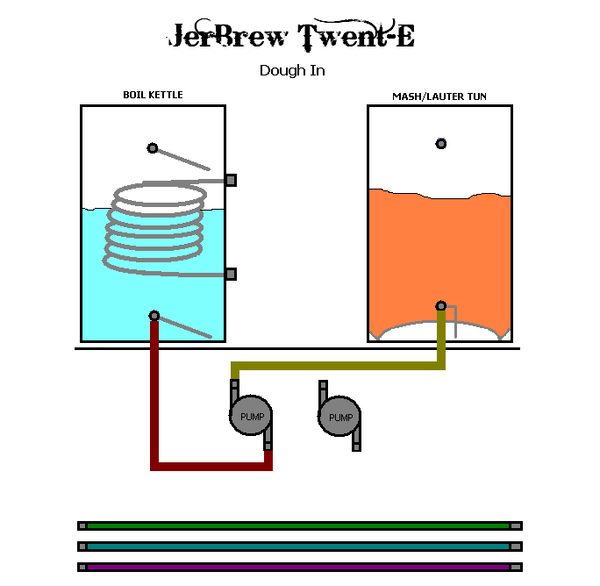

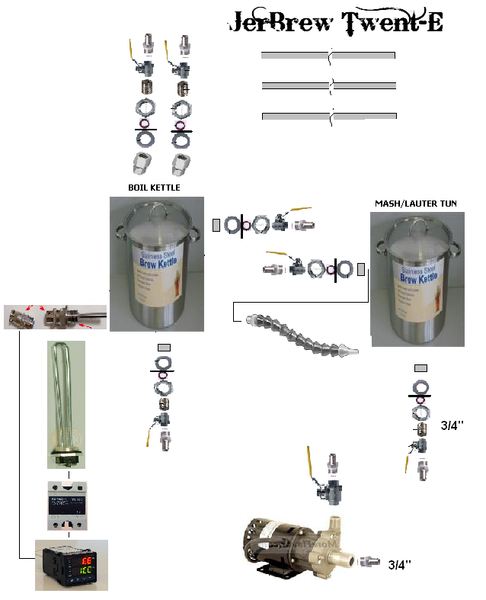

You don't need two burners or three heatable vessels. I'd go this way:

15 gallon kettle, 10 gallon MLT, two 6.5g ale pails.

I THINK those will nest into the 15g kettle.

There are two ways to handle liquid now.

Heat strike in kettle, move to MLT dough in and then ignore it for 60 minutes.

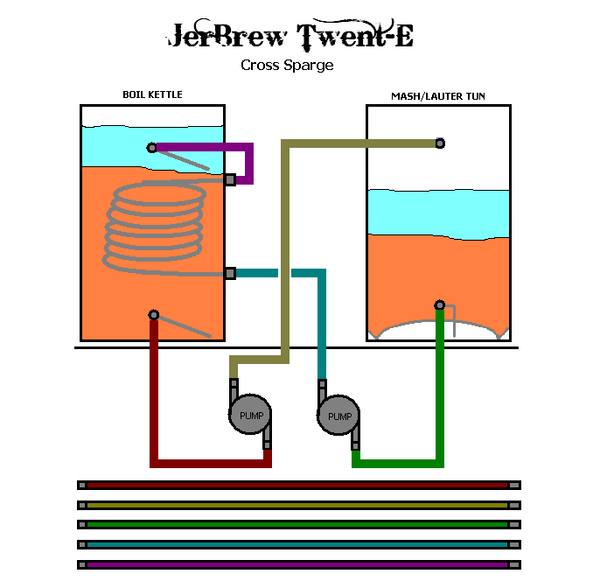

At that point heat the sparge in the kettle. When you're finished with the mash, you can either heat the strike ten degrees over sparge temp and hold that in the ale pails while you run off to the kettle (slightly faster getting the wort on the flame). Or you can run off into the pails and keep the sparge in the kettle until you're done. Batch sparging shouldn't take long anyway.

Advantages? Single burner. No real structure needed. No insulation needed on the MLT. Frankly, this is the same kind of system I started with and I miss the portability and simplicity of the whole operation.

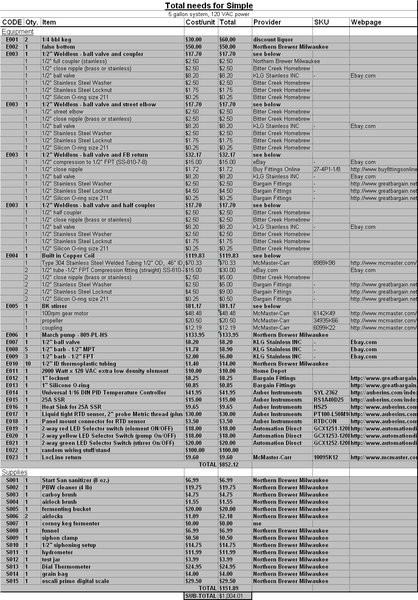

While I agree that on the surface the system's I have posted may seem expensive and complicated, they really aren't. The cooler and buckets idea would really only save him around $400 over the full BIAB solution with stand. ...

[

Cons:

-aluminum kettles (I know its fine, I have a problem will stainless desire)

Only? $400 is 10x 10 gallon AG batches. Quite a bit of money, I'd say.

Agreed, but being "cheap" can cause a lot of aggravation. My time is worth a lot to me, and so is my "state of mind." I actually partial mash BIAB a good bit. The extra cost is worth it for the ease. The extra $1.50 I have to spend on grain or the 3-4 pounds of extract I use is cheap compared to a nice relaxing brew day. Just my opinion, each of us enjoys the hobby differently.

On a slightly different note, after harvesting my hops, I realized I save a whopping $8 by growing my own. Not that I did it for the money (hop prices cam down since I plated them last year - and only the centennials actually produce any usable cones),but it was slightly disheartening...

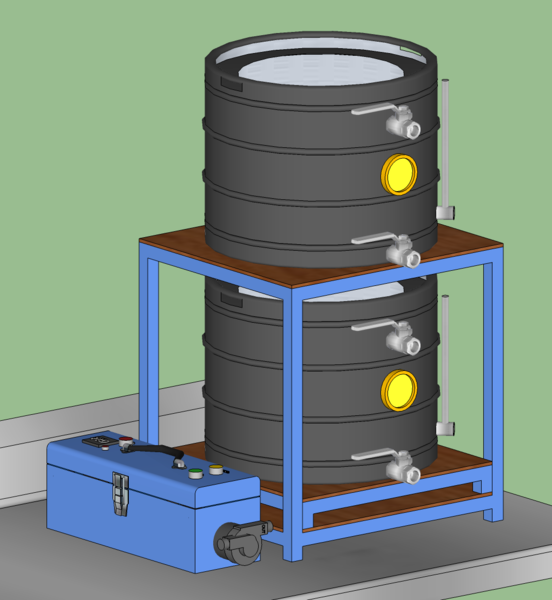

That is nice. Pricey as heck. Basically, I want to build something like that. It won't be nearly as pretty, but serve the same purpose.

... That Speidel is basically like an automated coffeemaker. You put in the ingredients, and drain off the finished wort.

Coolumb.

WOW.... just had a thought. Remove the burner and replace with a 115VAC heating element and you have the smallest AG system possible.