Another HERMS build thread!!!!

I know there's a lot of build threads on here already and I'd like to thank and give credit to the owners of which for the ideas I've gotten from you.

So I somehow managed to convince my academic adviser, who also happens to be the chairman of the UNH Electrical & Computer Engineering department, that for my senior engineering project he should let me build an electric brewery...

First off I'd like to point out that compared to most HBT members I'm still a newbie when it comes to my brewing knowledge, so please feel free to correct me whenever appropriate. I've been brewing for about 2 years now and probably have about 20 batches under my belt so far and only 4 of those have been all-grain batches. However it only took me a couple of day long all-grain brew sessions to realize that infusion step mashing is way too much work and frustration.

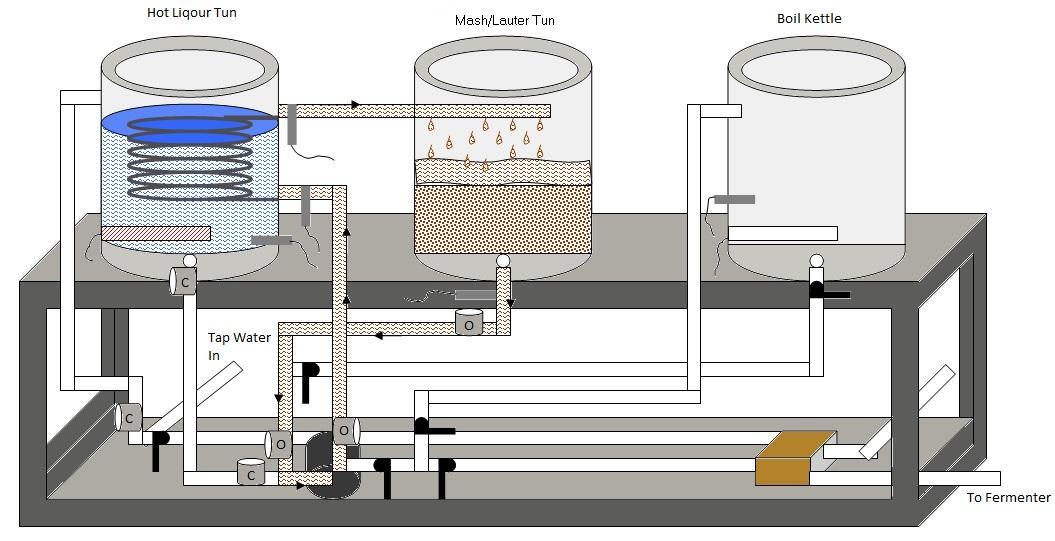

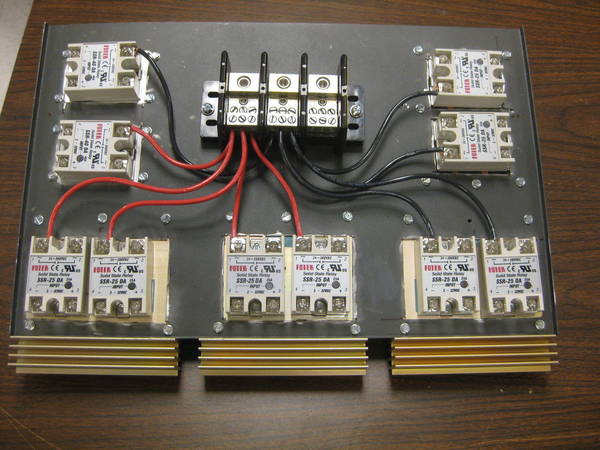

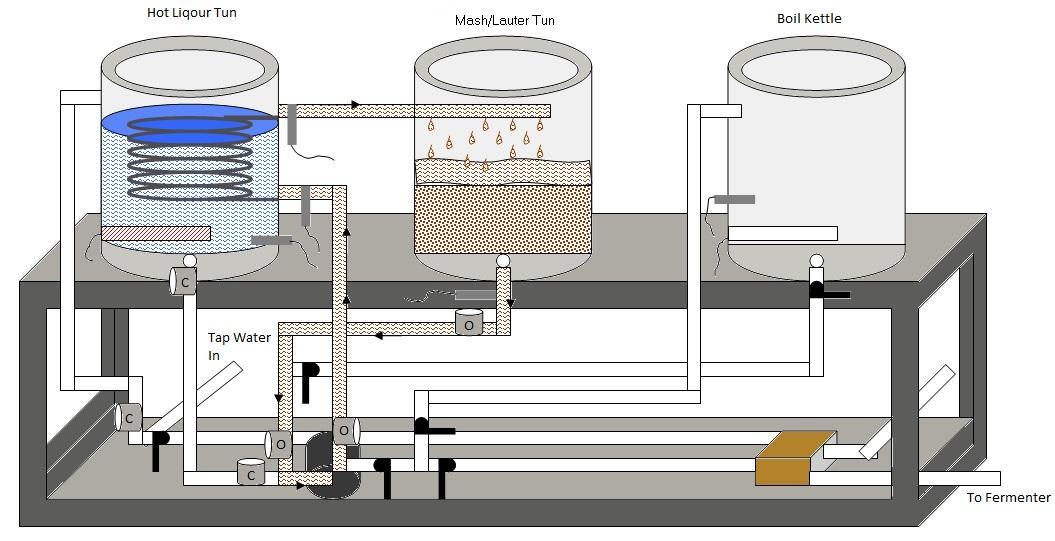

My plan is to build an automated electric HERMS system that i can run from my laptop with either labview or DAQfactory, using labjack and SSRs to read multiple temp probes and control my heating element, valves, and pump.

This is my current working design. I had originally had a 2 pump design with all solenoid valves but to save some money and complexity I'm limiting the automation to the mashing aspect. Transfers to the boil kettle will be with manual valves and might need to be with gravity if I'm using the pump for sparging.

I'd appreciate any advice and comments.

-John

I know there's a lot of build threads on here already and I'd like to thank and give credit to the owners of which for the ideas I've gotten from you.

So I somehow managed to convince my academic adviser, who also happens to be the chairman of the UNH Electrical & Computer Engineering department, that for my senior engineering project he should let me build an electric brewery...

First off I'd like to point out that compared to most HBT members I'm still a newbie when it comes to my brewing knowledge, so please feel free to correct me whenever appropriate. I've been brewing for about 2 years now and probably have about 20 batches under my belt so far and only 4 of those have been all-grain batches. However it only took me a couple of day long all-grain brew sessions to realize that infusion step mashing is way too much work and frustration.

My plan is to build an automated electric HERMS system that i can run from my laptop with either labview or DAQfactory, using labjack and SSRs to read multiple temp probes and control my heating element, valves, and pump.

This is my current working design. I had originally had a 2 pump design with all solenoid valves but to save some money and complexity I'm limiting the automation to the mashing aspect. Transfers to the boil kettle will be with manual valves and might need to be with gravity if I'm using the pump for sparging.

I'd appreciate any advice and comments.

-John