EdWort

Well-Known Member

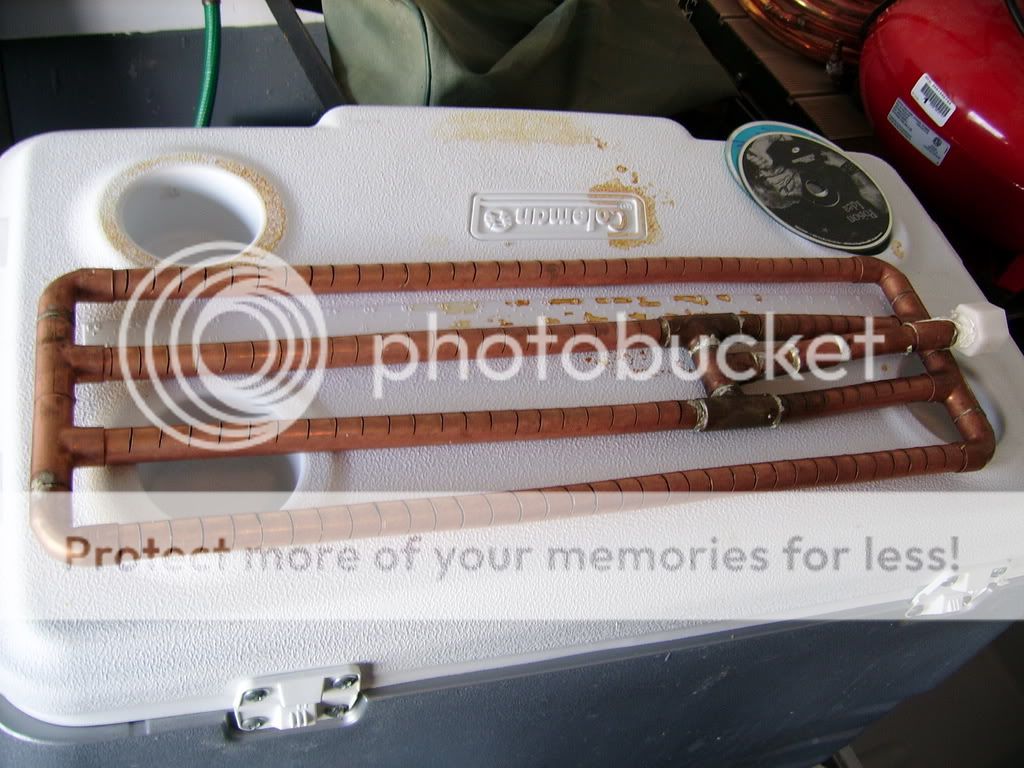

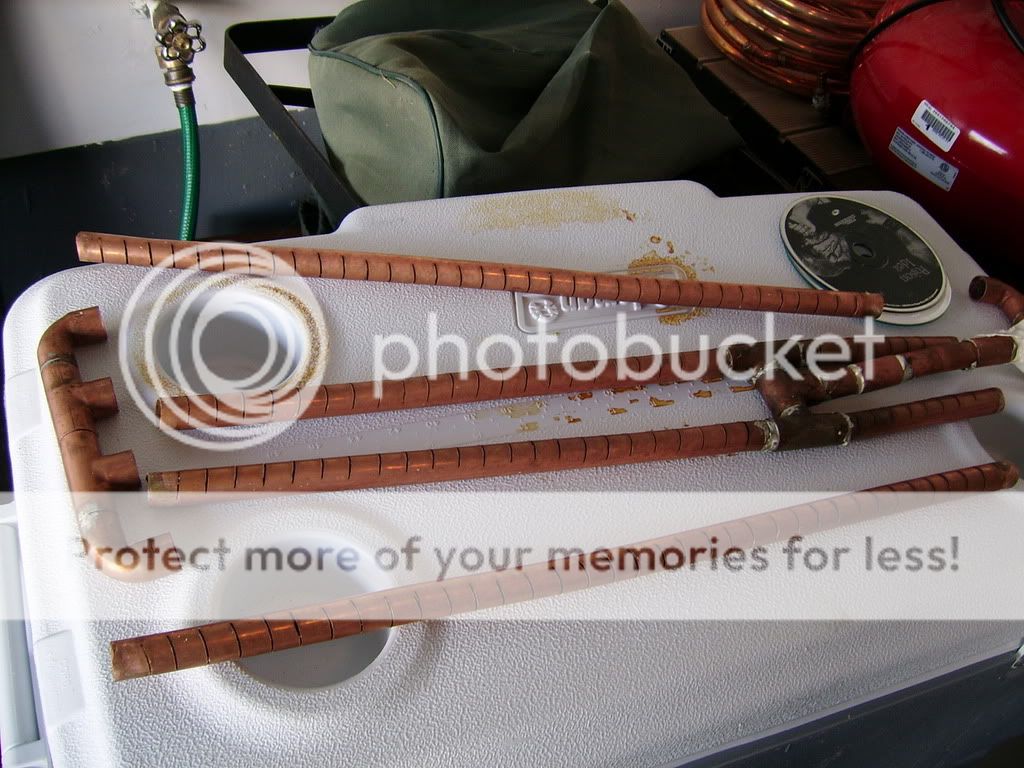

I sold my 10 gallon Rubbermaid MLT to brew bud and now need to make another one. I just picked up this 70 qt Coleman Extreme at Academy for $36. I need to put a ball valve on it and either a braid or build a manifold for it. I batch sparge, so I'm stoked that I'll be able to do bigger beers now with just one addition of hot water.

So, who has a braid and who has a manifold and what are your efficiencies for batch sparging?

So, who has a braid and who has a manifold and what are your efficiencies for batch sparging?