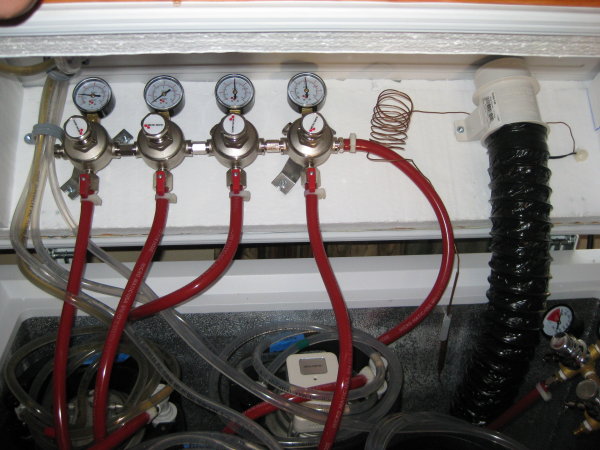

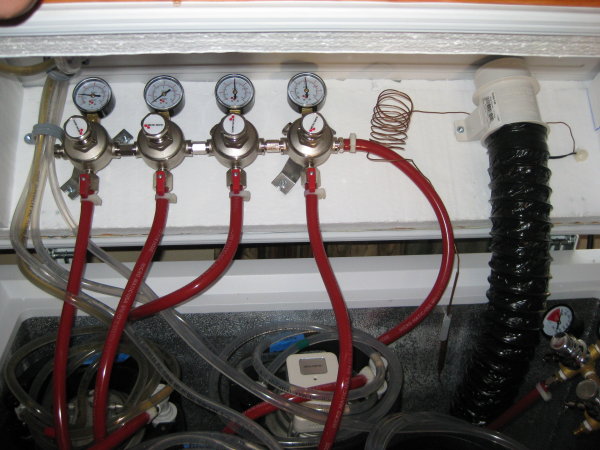

Pretty much done now. I have the system plumbed and the fan mounted along with the power and sensor running through the collar. The only thing I'm missing is one ten foot length of tubing for tap #4. Once I pick that up though it'll be easy enough to run.

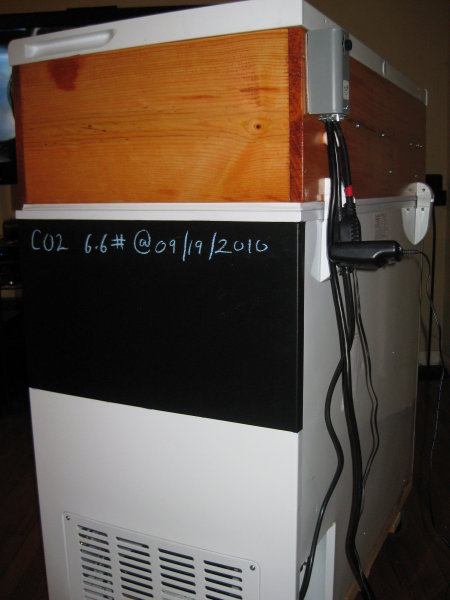

I switched back to the Johnson controller and ran everything through the collar then foamed the hole in. I ended up rewiring the Johnson controller to make my life easier. One plug is always on for my fan and the other is on the relay for the freezer. Saved me running three cords back to the wall.

Only real items I have left are the drip pan, which I have everything for just need to come up with a good way to do it, and dealing with air flow inside.

The chalk board wraps around the sides so plenty of room for notes and stuff I don't need out front.

In my testing I'm noticing that since the kegs are so tightly packed and sit so snuggly on the bottom of the freezer the pockets between them will be much cooler than the rest of the space and will ice up given half a chance.

I have plenty of head room though so plan to make a grid of wood or metal to raise them up a couple inches to improve air flow. With the fan pointing straight down at the hump this should increase circulation greatly. If needed I have ducting that I originally planned to run but didn't need. I might run it down so the fan blows directly into the void I create under the kegs.

Either way the bulk of the work is done and I'm sitting here drinking my first draft from it right now so... whoppie!