Surfing the internet looking for some budget price HW (fittings, pum..) for my project of conical fermenter cooler I have found this unbelievable controller and monitoring system..

The Aquaero 5 XT is manufactured in Germany from Aqua Computers

It’s a component that is sold as “fun controller” in PC watercooler system so nothing to do with specific brewery application or industrial automation (PLC) but I was attracted by the nice graphical display and the tons of I/O capabilities and devices…so I have started to go in further details and I have discovered very nice feature that stimulates my fantasy in using this “consumer” and budget price piece of HW in order to automate brewing process.

Just some quick overview in order to let you know the potentialities

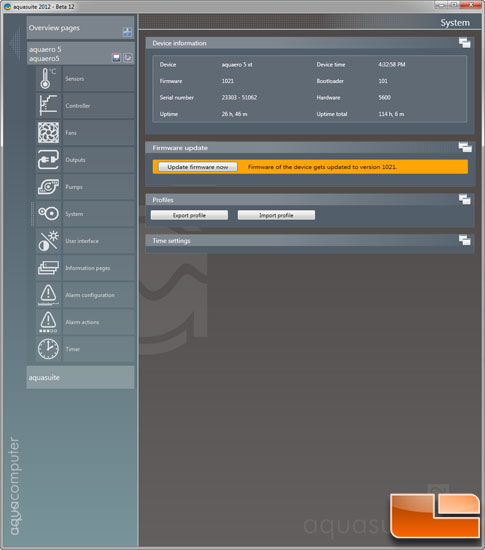

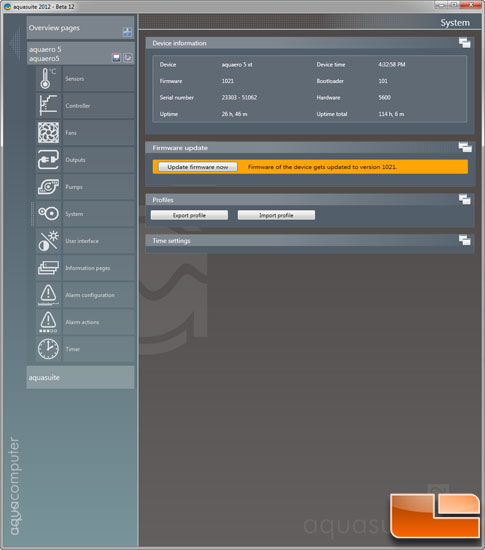

First of all the unit can work stand alone, is not need at all a computer connection, can be entirely configured by its own touchscreen and eventually can be connected via USB to a PC where a very powerfully controller software let you configure everything

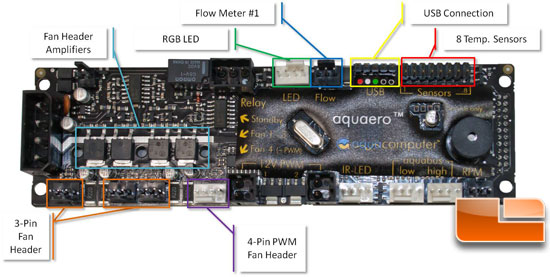

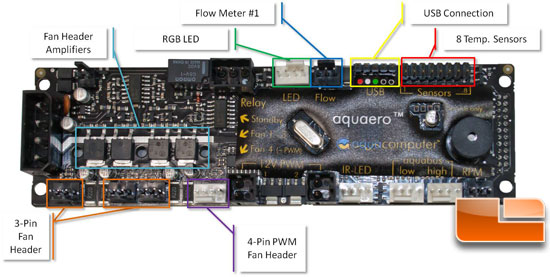

The board is provided with 8 temperature sensor input that can be virtually connected to any output..the basic principle is the following..

SENSOR -> controller -> ACTORS

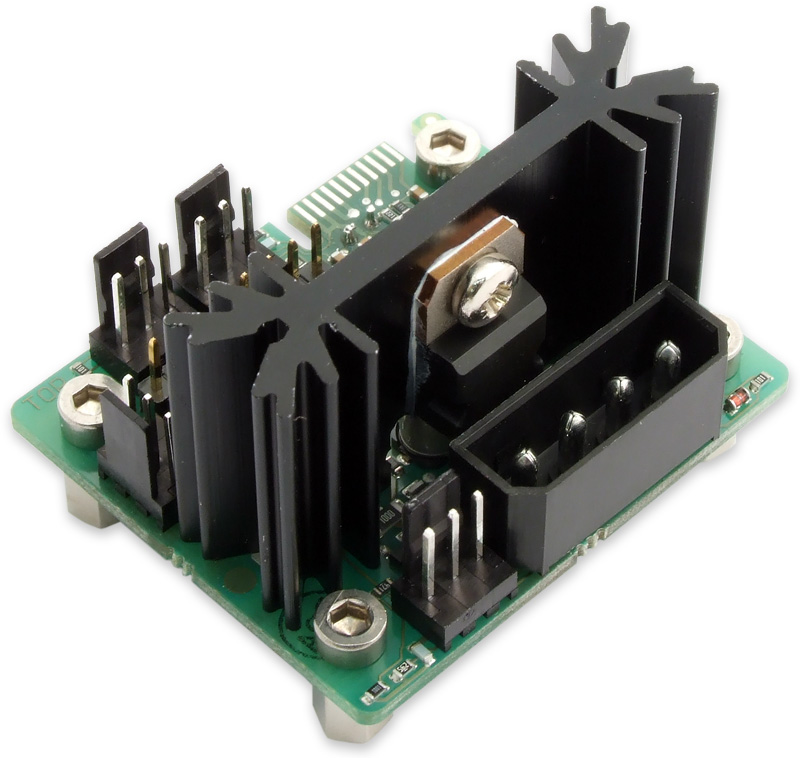

The main feature of the controller is the “fan controller” there are 4 fan channels that can be driven in the range 0-12v…this is good for lot of application like chillers and so on..but..you can use this output to drive more or less anything. For example you can drive an high power resistive load (heater) by simplu adding an SSR like this one from crydom

http://docs-europe.electrocomponents.com/webdocs/0b69/0900766b80b69c7c.pdf

Than you have 2 more PWM output : adding an h-bridge power circuit you can drive motors controlling speed, or a TEC cooler ..or again an heater modulating the power

You have also specific I/O like flow meter and level control as well rele output

In terms of control feature you have all possible otpions (PID, two points, manual, curve..)

Extensive logging capabilities allow you to cache 140.000 data in the device memory

Full set of alarm and warning could be used to drive switches and valves…and you have real time clock plus 32 timers configurable..

The full set of feature and a complete review can be found at that link..

http://www.legitreviews.com/article/1813/1/

I still don’t have a clear idea how to use this toy..but it seems to me powerful enough to be adapted to may situations in the brewing process. I know there are many other consumer (arduino..) and industrial control system but the compact design with a graphic display (plus USB connectivity and powerful software) for around 150 (price corrected) usd makes it very interesting…

What do you think about ??

Any idea how to customize for brewery automation?

Davide

The Aquaero 5 XT is manufactured in Germany from Aqua Computers

It’s a component that is sold as “fun controller” in PC watercooler system so nothing to do with specific brewery application or industrial automation (PLC) but I was attracted by the nice graphical display and the tons of I/O capabilities and devices…so I have started to go in further details and I have discovered very nice feature that stimulates my fantasy in using this “consumer” and budget price piece of HW in order to automate brewing process.

Just some quick overview in order to let you know the potentialities

First of all the unit can work stand alone, is not need at all a computer connection, can be entirely configured by its own touchscreen and eventually can be connected via USB to a PC where a very powerfully controller software let you configure everything

The board is provided with 8 temperature sensor input that can be virtually connected to any output..the basic principle is the following..

SENSOR -> controller -> ACTORS

The main feature of the controller is the “fan controller” there are 4 fan channels that can be driven in the range 0-12v…this is good for lot of application like chillers and so on..but..you can use this output to drive more or less anything. For example you can drive an high power resistive load (heater) by simplu adding an SSR like this one from crydom

http://docs-europe.electrocomponents.com/webdocs/0b69/0900766b80b69c7c.pdf

Than you have 2 more PWM output : adding an h-bridge power circuit you can drive motors controlling speed, or a TEC cooler ..or again an heater modulating the power

You have also specific I/O like flow meter and level control as well rele output

In terms of control feature you have all possible otpions (PID, two points, manual, curve..)

Extensive logging capabilities allow you to cache 140.000 data in the device memory

Full set of alarm and warning could be used to drive switches and valves…and you have real time clock plus 32 timers configurable..

The full set of feature and a complete review can be found at that link..

http://www.legitreviews.com/article/1813/1/

I still don’t have a clear idea how to use this toy..but it seems to me powerful enough to be adapted to may situations in the brewing process. I know there are many other consumer (arduino..) and industrial control system but the compact design with a graphic display (plus USB connectivity and powerful software) for around 150 (price corrected) usd makes it very interesting…

What do you think about ??

Any idea how to customize for brewery automation?

Davide