DharkMeadBrewer

Active Member

- Joined

- Jan 22, 2008

- Messages

- 35

- Reaction score

- 0

so it occurred to me the other day that I am going to be buying CO2 (I just started kegging), and I was producing plenty of the stuff when I was fermenting my beer. Now I understand its impossible (read to damn expensive) for me to reproduce the amount of pressure I would get when I buy the co2 from the store (I believe its something like 830 psi until the liquid CO2 is depleted), but I thought It would be novel and I just don't like the thought of throwing away something only to buy the same exact thing.

The thought I had was this:

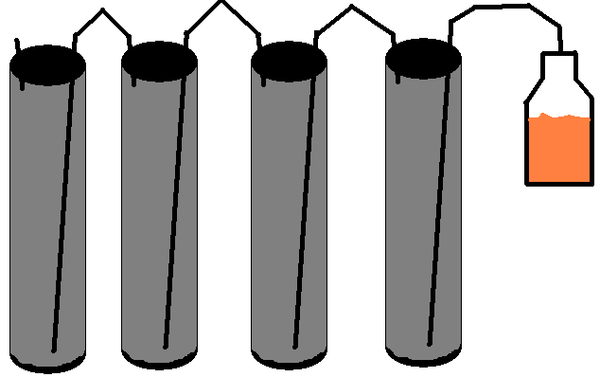

I collect the CO2 over water by piping the carboy into a C02 "reservoir" and then pumping it into an air compressor that I have had vacuum pumped (to remove nearly all the air). The C02 reservoir would have a float switch which kicked the compressor on and off. it would also have a port to the water reservoir, which would allow the water to escape the co2 reservoir when displaced. The water reservoir would have to be weighted on a see saw like thing so that as it filled with water it would fall as to keep the whole system zero pressure.

any obvious shortcomings?

The thought I had was this:

I collect the CO2 over water by piping the carboy into a C02 "reservoir" and then pumping it into an air compressor that I have had vacuum pumped (to remove nearly all the air). The C02 reservoir would have a float switch which kicked the compressor on and off. it would also have a port to the water reservoir, which would allow the water to escape the co2 reservoir when displaced. The water reservoir would have to be weighted on a see saw like thing so that as it filled with water it would fall as to keep the whole system zero pressure.

any obvious shortcomings?