kpr121

Well-Known Member

I posted this in the Water fermentation chiller thread but would like to ask the questions here seperately:

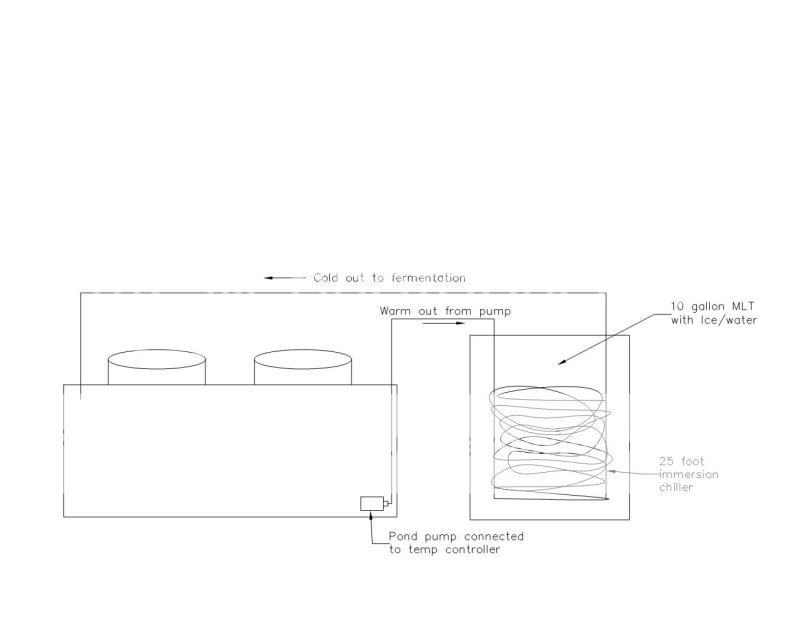

Does anyone use the following as fermentation control or have any opinions/ideas? I want to use my immersion chiller and pond pump set up as is without much modification. If I put the IC copper coil in my 10g water cooler mash tun filled with ice water, the pump in my Rubbermaid container where the fermenters are, and plug the pump into an ebay temperature controller, theoretically it should work correct?

This way I don’t have to worry about overflow pipes, both containers can stay on the floor, and all the water being pumped will end up right back where it came from. The only issue I can see is stratification of the chilling water in the mash tun, but I think it should still work. I guess if its taking too long I could throw a small aquarium pump in the cooler to keep the ice water turbulent.

I figure this is the best way to use the equipment I already have, and since I almost never do back to back days of brewing, the equipment can basically be utilized at all times. If I brew the following week, usually the beer has fermented to FG and temp control is not as necessary. So I would be pulling the first batch out of the Rubbermaid, and replacing it with the new batch. After cleaning the IC and mash tun, it goes back to fermentation chill mode. (This would give me incentive to clean my equipment right away as well lol).

Does anyone use the following as fermentation control or have any opinions/ideas? I want to use my immersion chiller and pond pump set up as is without much modification. If I put the IC copper coil in my 10g water cooler mash tun filled with ice water, the pump in my Rubbermaid container where the fermenters are, and plug the pump into an ebay temperature controller, theoretically it should work correct?

This way I don’t have to worry about overflow pipes, both containers can stay on the floor, and all the water being pumped will end up right back where it came from. The only issue I can see is stratification of the chilling water in the mash tun, but I think it should still work. I guess if its taking too long I could throw a small aquarium pump in the cooler to keep the ice water turbulent.

I figure this is the best way to use the equipment I already have, and since I almost never do back to back days of brewing, the equipment can basically be utilized at all times. If I brew the following week, usually the beer has fermented to FG and temp control is not as necessary. So I would be pulling the first batch out of the Rubbermaid, and replacing it with the new batch. After cleaning the IC and mash tun, it goes back to fermentation chill mode. (This would give me incentive to clean my equipment right away as well lol).