homebrewer_99

Well-Known Member

- Joined

- Feb 1, 2005

- Messages

- 19,581

- Reaction score

- 1,217

- Location

- I-80, Exit 27 (near the Quad Cities)

OK, I've asked around a few times, but now I have to start a thread on the subject.

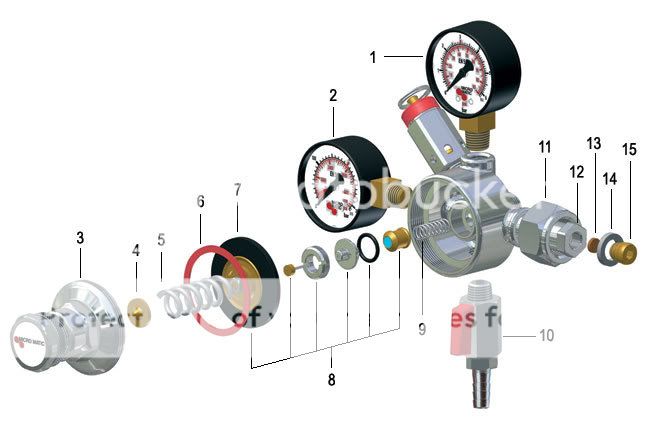

Can anyone enlighten me (and others) as to HOW a regulator works?

How do you know if gas/air is being transferred? (I heard nothing) How much? What does turing the screw do for you? And why does the dial indicator go up and down when turning the screw?

I just got a tank filled, but the second gage reads I need to refill the tank...personally, I think it's DOA. I turned the knob off last night and this morning both gages were reading nedds to refill and the other at 20 psi.

I'm sure there are other questions, but that's all I can think of at the moment...

Can anyone enlighten me (and others) as to HOW a regulator works?

How do you know if gas/air is being transferred? (I heard nothing) How much? What does turing the screw do for you? And why does the dial indicator go up and down when turning the screw?

I just got a tank filled, but the second gage reads I need to refill the tank...personally, I think it's DOA. I turned the knob off last night and this morning both gages were reading nedds to refill and the other at 20 psi.

I'm sure there are other questions, but that's all I can think of at the moment...