I'm in the very early stages of planning my brewstand/brewery. It's still in the "hopes and dreams" stage actually. Since I have very little mechanical ability and NO experience with ventilation requirements, I need some input from you guys.

Here's what I'm thinking- I have a small first floor laundry room. There is an exterior door there that opens, and it's only a one-story part of the house. There is also a door to close it off from the house. I was thinking that maybe ventilation could be acheived with a range hood (probably more expensive, since there is an attic above), or the door open, or building the vents into that exterior door which is never, ever used.

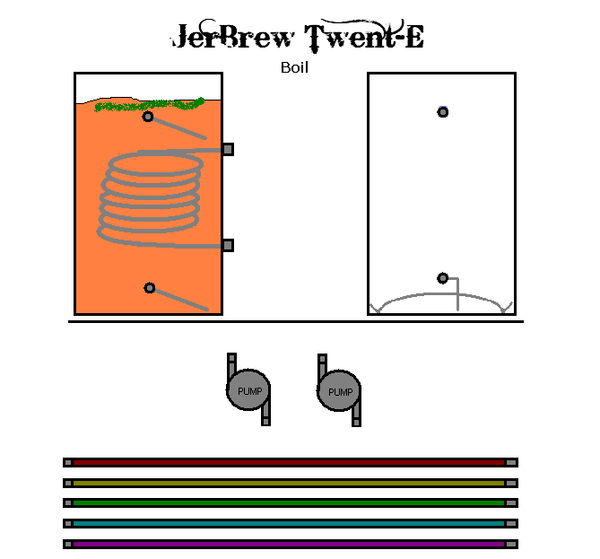

I was also thinking about a three tier, so I wouldn't have to use pumps since I'm no mechanical genius. Also, perhaps an electric HLT, so the co2 possibility is minimized. Now, the three tier couldn't be too terribly high, since I have 9 foot ceilings, but it could definitely be high enough I would think. I want wheels, to be able to move it into place when needed and out of the way when not, since the washer and dryer have to stay. The other thought is a two tier, with one pump. For the tier with the MLT, I would want a tippy dump since I'm a weakling.

So, where do I start? Do I find out about ventilation requirements? What do I do to get an electric HLT prebuilt? I don't have a 220/240 in my home currently, so I'd have to hire someone for that.

Is there a "brewery for dummies" place I can find this out? That's what I need.

Here's what I'm thinking- I have a small first floor laundry room. There is an exterior door there that opens, and it's only a one-story part of the house. There is also a door to close it off from the house. I was thinking that maybe ventilation could be acheived with a range hood (probably more expensive, since there is an attic above), or the door open, or building the vents into that exterior door which is never, ever used.

I was also thinking about a three tier, so I wouldn't have to use pumps since I'm no mechanical genius. Also, perhaps an electric HLT, so the co2 possibility is minimized. Now, the three tier couldn't be too terribly high, since I have 9 foot ceilings, but it could definitely be high enough I would think. I want wheels, to be able to move it into place when needed and out of the way when not, since the washer and dryer have to stay. The other thought is a two tier, with one pump. For the tier with the MLT, I would want a tippy dump since I'm a weakling.

So, where do I start? Do I find out about ventilation requirements? What do I do to get an electric HLT prebuilt? I don't have a 220/240 in my home currently, so I'd have to hire someone for that.

Is there a "brewery for dummies" place I can find this out? That's what I need.