ReuFroman

Well-Known Member

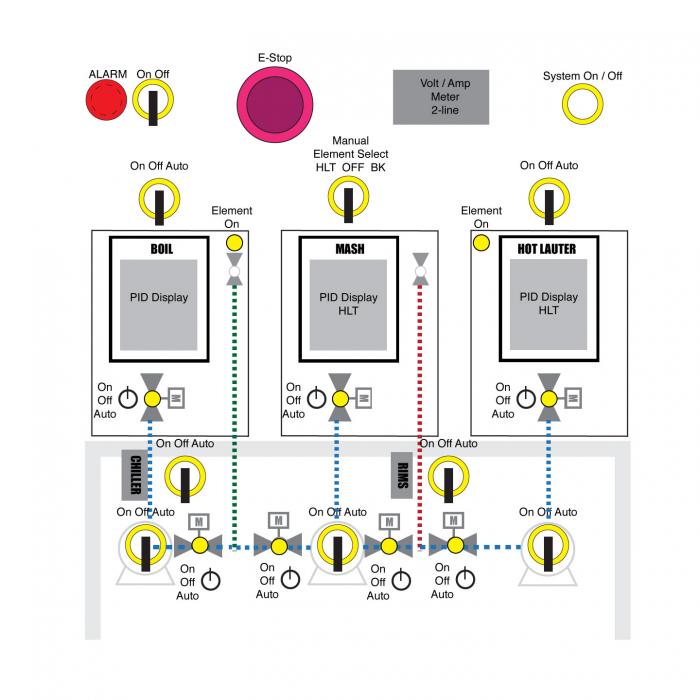

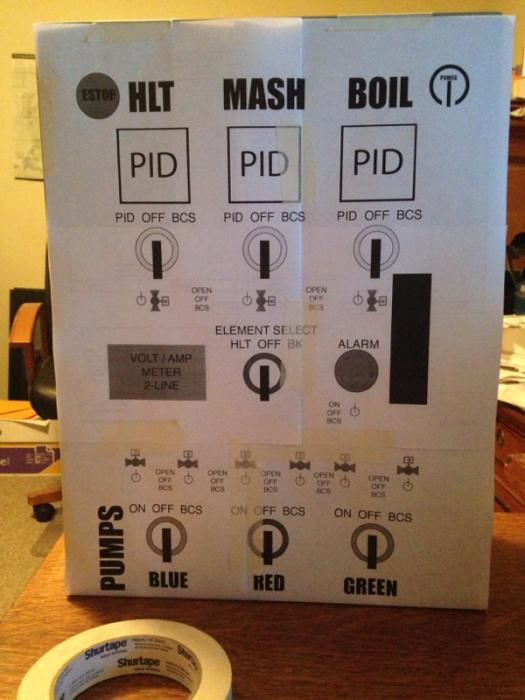

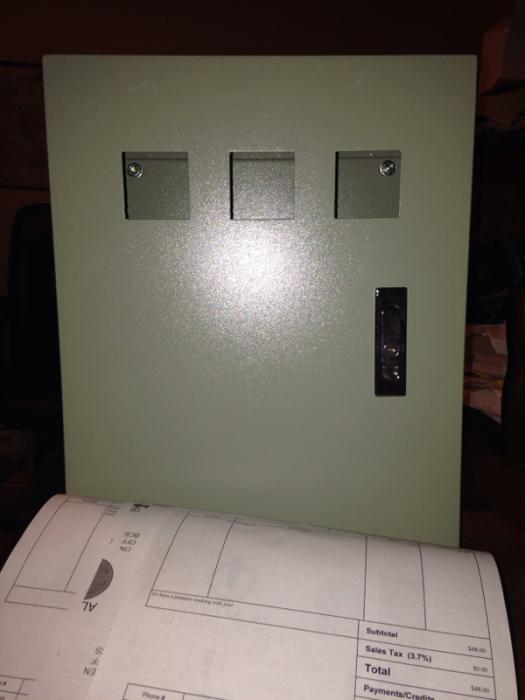

I'm getting ready to go electric, bcs or BT, and I want to make sure I have manual override for everything. I came up with this layout on a 20x20 box.

Thoughts, Ideas, Suggestions, Don't Do that's?

Thanks for your input.

Thoughts, Ideas, Suggestions, Don't Do that's?

Thanks for your input.