wyzazz

Well-Known Member

Steve, out of curiosity what are you using for a 1/16 DIN timer? Thanks!

details on that sight glass ? looks like the real deal.

BTW - nice build. I've been subscribed for a while now.

Steve, out of curiosity what are you using for a 1/16 DIN timer? Thanks!

Steve, good suggestion about the "third hand", what stores would carry something like that?

I got mine at Marc's, but The Shack should carry them as well.

Well...I got mine on Amazon....it's THIS ONE Really pretty cheap and does what it says (love stuff like that!)....it has a cast iron base and wing-nuts that you can crank down....very important because it will keep a firm grip on stuff so when you touch your soldering iron to the part it won't move.

Great thread Steve,

Took me two weeks of lunches to get through it properly. I have limited space where I plan to brew and I will use your work(and others you linked to) as a guide. Thanks for all the effort in putting this together!

Mike

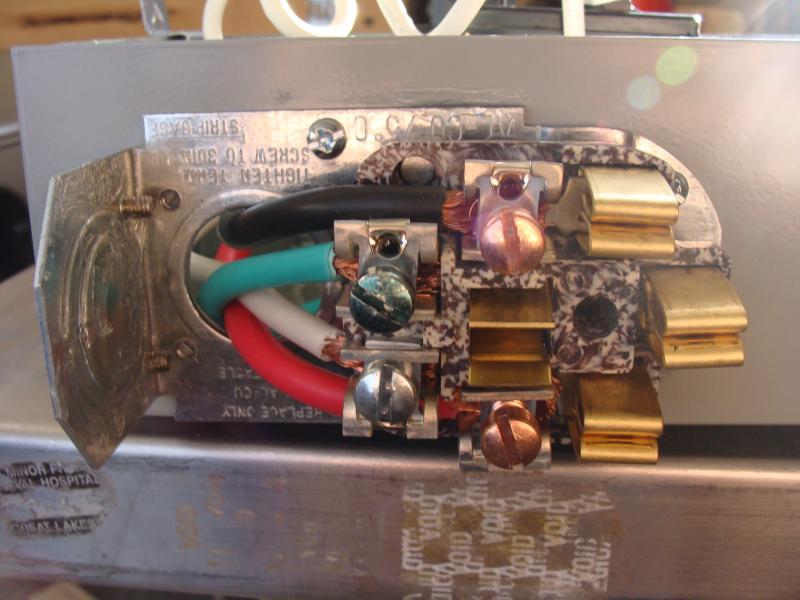

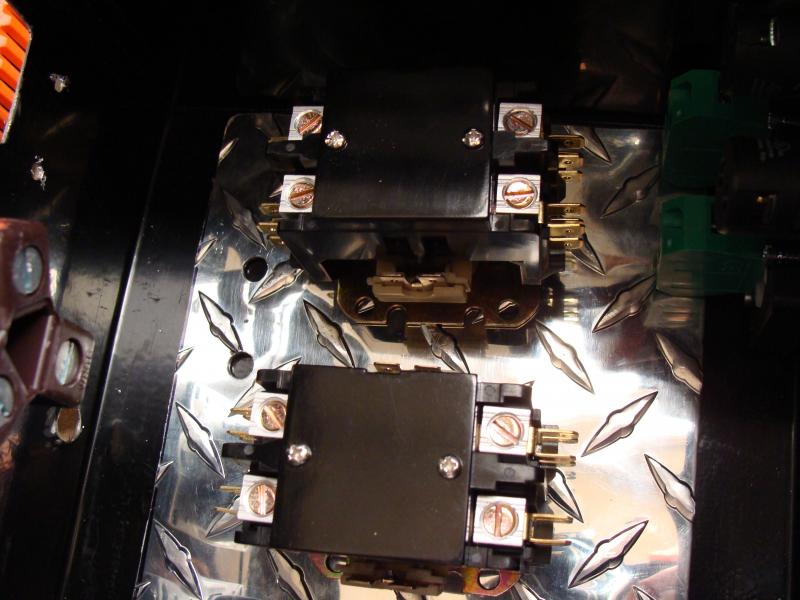

Nice! So how are you planning on branching this off inside the control panel?

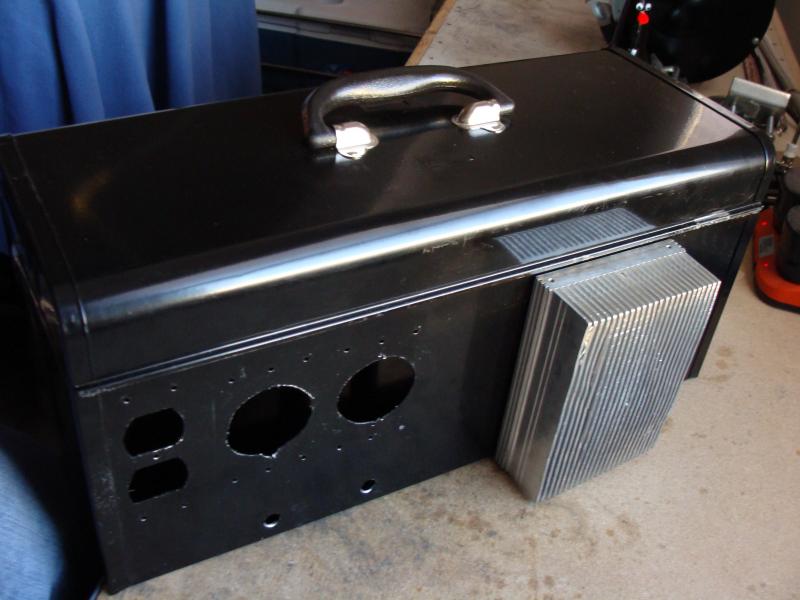

I'm thinking about getting a cool "missile launcher" switch for the power.

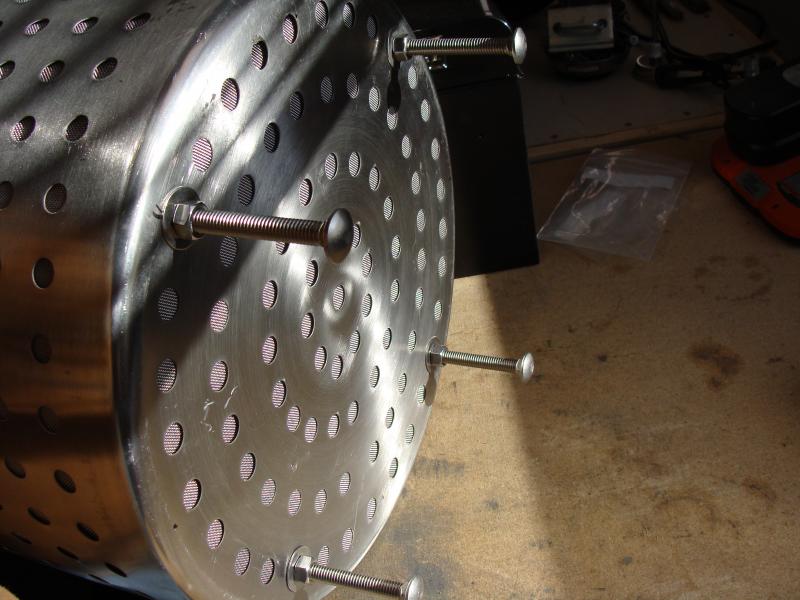

Just got done going through all 47 pages of this thing. Great build and I love your ingenuity. Do you plan to remove the basket for the boil or use the basket as a hop catcher/screen? If so do you forsee any problems boiling with the basket in the kettle?

Mark

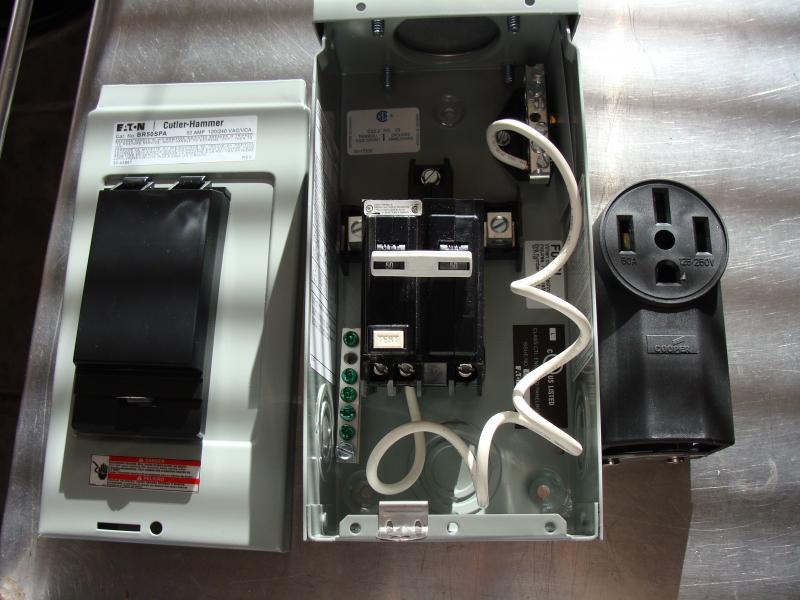

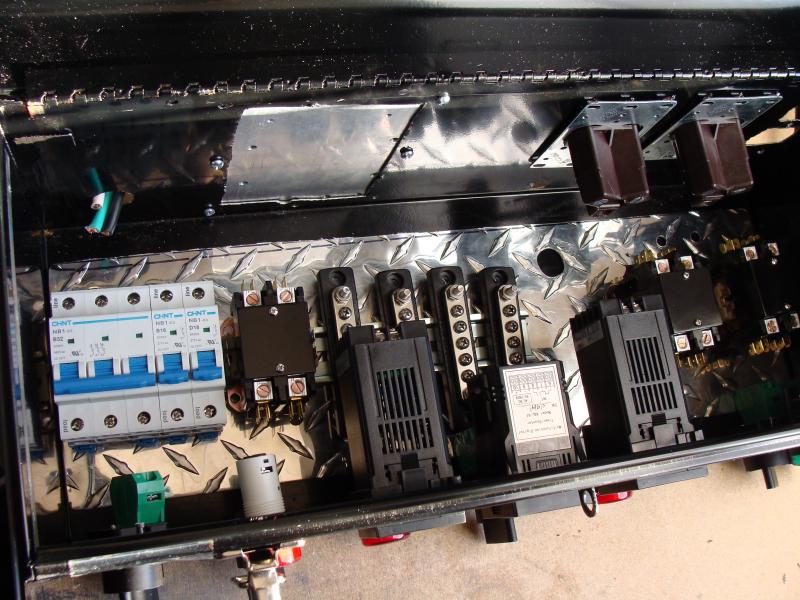

Steve I just noticed you're using a 3Pole breaker, any particular reason why?

P.S....Just got a TIG welder with the ol' tax refund....this hobby is a curse!

P.S....Just got a TIG welder with the ol' tax refund....this hobby is a curse!

Now you're going to have to redo all those solder joints you made.

Enter your email address to join: