I've started to put together my single tier all grain brewery, it is loosely based off of a Brutus Ten set up but will have a HERMS coil in the HLT, the system will be heated by two LP burners. The stand will be constructed using super strut so no welding necessary. I'm am going to control the gas valve with a PID, so the big question I have is what type of PID should I use, there are TONS of options, what PIDs should I stay away from? What thermocouples are the best to use? The brewery will only have one auto burner, two pumps, three keegles, one each for the HLT, MLT, and BK.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New single tier AG build

- Thread starter herc1354

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

mikescooling

Well-Known Member

Nice, I just got mine up and running and it changes brewing, it's so much nicer, less work, cooler, makes more beer faster. It's like Heaven. When I die, I'm going to a brewery. Anyway chugger pumps is having march maddness and they are selling cheep pumps. I have one and it works great. And get the fittings from Bobby M, I got his add a pump kit, it rocks.

runningweird

Well-Known Member

I hadn't seen the super strut stuff before, interesting. can you ballpark the cost for just the stand?

are you going to paint it?

are you going to paint it?

cracked1

Well-Known Member

I hadn't seen the super strut stuff before, interesting. can you ballpark the cost for just the stand?

are you going to paint it?

There's a whole thread on strut builds... https://www.homebrewtalk.com/f51/my-weldless-build-using-strut-363128/

OP, nice job. Looks almost exactly like the strut stand I built.

runningweird said:I hadn't seen the super strut stuff before, interesting. can you ballpark the cost for just the stand?

are you going to paint it?

Ball park is about $150.00. Not sure if I'm going to paint it, depends on how it looks after brewing.

cracked1 said:There's a whole thread on strut builds... https://www.homebrewtalk.com/f51/my-weldless-build-using-strut-363128/

OP, nice job. Looks almost exactly like the strut stand I built.

Thanks! Just need to mount my pumps and banjo burners

mikescooling said:Nice, I just got mine up and running and it changes brewing, it's so much nicer, less work, cooler, makes more beer faster. It's like Heaven. When I die, I'm going to a brewery. Anyway chugger pumps is having march maddness and they are selling cheep pumps. I have one and it works great. And get the fittings from Bobby M, I got his add a pump kit, it rocks.

Yeah Bobby is the go to guy for fittings and pumps, I got ALL my fittings, hose and pumps from him, I may have been one of the resigns he had to shut down for a few day to restock.

Finally I got to brew on my set-up, first all gran brew....WOW, what a mess....

My biggest issue was in how long it took to heat water. I'm using bg-14 burners converted to low pressure LP, the HLT is controlled with a PID. The automation worked great but took forever to get my water up to temps. I know heating 10 gallons of water is not a fast process but crap, it took 2 hours to reach a boil with 10 gallons of Wort. I killed a full LP gas grill bottle plus what was left in another which was about 1/4 full. I'm thinking my burners my be too low, but at 6" from the bottom of the BK and HLT I would think that would be sufficient.

Hopefully someone will see the errors in my ways or give some suggestions. For now I'm going to rash the burners and see if that helps.

My biggest issue was in how long it took to heat water. I'm using bg-14 burners converted to low pressure LP, the HLT is controlled with a PID. The automation worked great but took forever to get my water up to temps. I know heating 10 gallons of water is not a fast process but crap, it took 2 hours to reach a boil with 10 gallons of Wort. I killed a full LP gas grill bottle plus what was left in another which was about 1/4 full. I'm thinking my burners my be too low, but at 6" from the bottom of the BK and HLT I would think that would be sufficient.

Hopefully someone will see the errors in my ways or give some suggestions. For now I'm going to rash the burners and see if that helps.

Yeah those are super low, I would raise them up as high as possible with keggles. I bought a bayou classic kab4 and the way it came it was about 6" from the keggle. I modified it to be as high as possible and now it works great, I can only run it about 50% or its too much. If you had wind guards on them like what come on the kab4 or the blichman burner it would help but they need to be raised up.

bd2xu said:Yeah those are super low, I would raise them up as high as possible with keggles. I bought a bayou classic kab4 and the way it came it was about 6" from the keggle. I modified it to be as high as possible and now it works great, I can only run it about 50% or its too much. If you had wind guards on them like what come on the kab4 or the blichman burner it would help but they need to be raised up.

Cool, thanks! Last night was a complete cluster. Ill get on raising them.

herc1354 said:Cool, thanks! Last night was a complete cluster. Ill get on raising them.

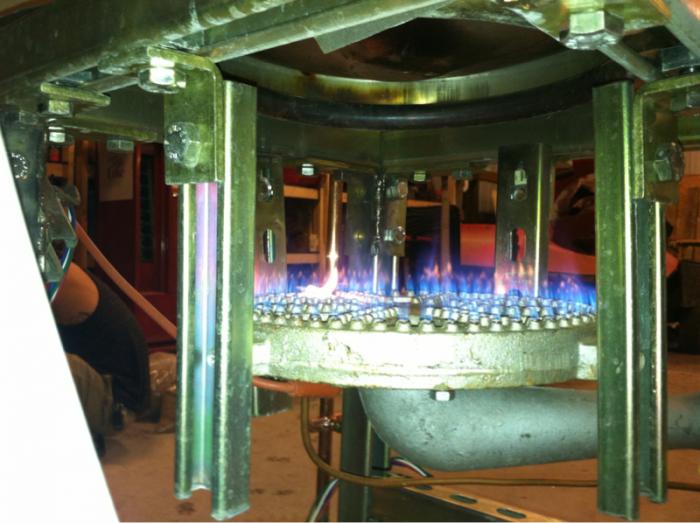

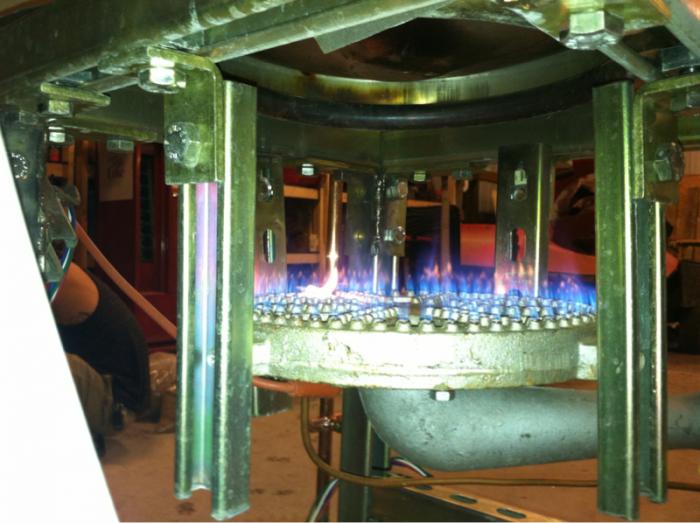

Here is my kab4, hard to tell from this pic but you can see the flame and can tell how I raised the burner all the way up by the u bolts on the outside. Made a HUGE diff. Especially with no wind guards you a losing a ton of heat.

bd2xu said:Here is my kab4, hard to tell from this pic but you can see the flame and can tell how I raised the burner all the way up by the u bolts on the outside. Made a HUGE diff. Especially with no wind guards you a losing a ton of heat.

It's funny, last night during the brew from hell I noticed a tone of heat escaping from the brew stand. How long does it take you to boil 10gal ?

bd2xu said:I really haven't measured it but it seems like it performs well. I know that the liquid in my sight glass boils if I crank too high and i have to spray it down with water to cool it off.

As I'm thinking about it I'm not sure why I set the burners so low, I know gas stove burners are extremely close to the grates that the cookware sits on. Out of curiosity how long does it take you to get to boil temps with your burner?

herc1354 said:As I'm thinking about it I'm not sure why I set the burners so low, I know gas stove burners are extremely close to the grates that the cookware sits on. Out of curiosity how long does it take you to get to boil temps with your burner?

I haven't measured yet but I'd say I heat the collected wort from 160-170 to boiling in 15 mins or so.

These are high pressure burners but each hole is small so it's more about the overall surface area. I think banjos need to be relatively close to the vessel, unlike jet style burners. Look at the blichman burner, for example. It's the same burner, just a 10" banjo. look at the distance from the pot. And that's for flat bottomed vessels, I think kegs need to be a little closer because the skirt adds some distance.

bd2xu said:I haven't measured yet but I'd say I heat the collected wort from 160-170 to boiling in 15 mins or so.

These are high pressure burners but each hole is small so it's more about the overall surface area. I think banjos need to be relatively close to the vessel, unlike jet style burners. Look at the blichman burner, for example. It's the same burner, just a 10" banjo. look at the distance from the pot. And that's for flat bottomed vessels, I think kegs need to be a little closer because the skirt adds some distance.

Thanks, this helps a lot. Next brew is in two weeks, but before then ill adjust the burners and do a heat test.

Nickeldeposit

Well-Known Member

I've got the same issue with low flame intensity on my low pressure system using the BG 14. Really weak flame and the air disk has to be wide open to even begin to get mostly blue flame.

Nickeldeposit said:I've got the same issue with low flame intensity on my low pressure system using the BG 14. Really weak flame and the air disk has to be wide open to even begin to get mostly blue flame.

I don't feel like I have low flame intensity, with my burner lit and on high the heat generated was insane. As I mentioned early look at a gas cooktop, the distance from the burner to the cookware is very close. I'm starting to think I was drunk when I set my burners 6" from the bottom of my kettles. Another thing that I have to take in consideration is I'm using kegs which we all know do not have a flat bottom, this was I'm sure a factor in heat distribution.

GoodDogShelby

Well-Known Member

Herc:

I have a two burner system, HP 10" banjo for the BK & LP 6" banjo for the HLT controlled by a Honeywell valve. When I first built the rig it was taking forever to heat strike water. My looked at what I was doing and said, "Dad, why don't you just use the 'big honk'n' burner?". He was right. Now I start water heating in my BK under the high pressure 10" banjo. When I get close to strike temp, I pump it all to the HLT and let the gas valve do the work of dialing it into the final temp. That move has cut at least 45 minutes out of my brew cycle.

I have a two burner system, HP 10" banjo for the BK & LP 6" banjo for the HLT controlled by a Honeywell valve. When I first built the rig it was taking forever to heat strike water. My looked at what I was doing and said, "Dad, why don't you just use the 'big honk'n' burner?". He was right. Now I start water heating in my BK under the high pressure 10" banjo. When I get close to strike temp, I pump it all to the HLT and let the gas valve do the work of dialing it into the final temp. That move has cut at least 45 minutes out of my brew cycle.

GoodDogShelby said:Herc:

I have a two burner system, HP 10" banjo for the BK & LP 6" banjo for the HLT controlled by a Honeywell valve. When I first built the rig it was taking forever to heat strike water. My looked at what I was doing and said, "Dad, why don't you just use the 'big honk'n' burner?". He was right. Now I start water heating in my BK under the high pressure 10" banjo. When I get close to strike temp, I pump it all to the HLT and let the gas valve do the work of dialing it into the final temp. That move has cut at least 45 minutes out of my brew cycle.

Yeah I was thinking about doing something like that. My burners are the bg-14 banjo burners, so I think they are defiantly large enough, once I raise the burners I'm going to do a boil test starting with cold water. If the heat up times are still long ill probably go the direction you have gone.

Thanks for the input, I really appreciate it.

herc1354 said:Very cool, good luck!

Starting out bad. I was just about to start setting up and the sky opened up. I think it's rained every day for 6+ weeks in Atlanta!!! Going to be a late night.

bd2xu said:Starting out bad. I was just about to start setting up and the sky opened up. I think it's rained every day for 6+ weeks in Atlanta!!! Going to be a late night.

How did everything go? It's been very wet in NC this year, come to think about it I'm sure it rained the day I brewed, luckily my setup is in the Barn.

Stealthcruiser

Well-Known Member

Starting out bad. I was just about to start setting up and the sky opened up. I think it's rained every day for 6+ weeks in Atlanta!!! Going to be a late night.

Don't let that stop ya', it'll help keep the dust down!..........

Get a couple of golf umbrellas or a patio table umbrella, and clamp it to your brewstand.

Burners look very far from keggles and flame looks very small. Probable cause for long boil time.

musikguru6

Well-Known Member

The maiden voyage of mine is tonight! Doing a ten gallon batch of dunkel weizen.

View attachment 143452

View attachment 143453

View attachment 143454

Just built this monster chiller last night. 50' of 1/2 ID tube... Huge

Assume your burners are bg14s? If so, what parts did you use to mount them to the stand?

Also - where did you purchase your equipment for the gas lines?

The HLT an bk are 14g. The mt is six inch. Used L brackets for the 14s and L brackets plus some strut for the 6. Home Depot for gas lines except I had to order the needle valves from Bayou classic.musikguru6 said:Assume your burners are bg14s? If so, what parts did you use to mount them to the stand? Also - where did you purchase your equipment for the gas lines?

Correct, got everything at Home Depot except for the needle valves which I could not find anywhere but online. Bought them from Bayou classic. They are crucial in the set up.d_boosh said:Most of the gas lines look like galvanized pipe with the yellow pipe tape for gas on the connections. The yellow flex lines are standard appliance hookups. All should be available at any hardware store.

Most of the gas lines look like galvanized pipe with the yellow pipe tape for gas on the connections. The yellow flex lines are standard appliance hookups. All should be available at any hardware store.

You do not want to use galvanized pipe for gas lines, the galvanization can flake off and clog the orifices. The gas can actually erode it where there is a elbow etc.. I have never seen this happen but that's what they say and even the signage at my local Lowes says NOT to use it for gas and to use Black Iron Pipe.

Daves69 said:You do not want to use galvanized pipe for gas lines, the galvanization can flake off and clog the orifices. The gas can actually erode it where there is a elbow etc.. I have never seen this happen but that's what they say and even the signage at my local Lowes says NOT to use it for gas and to use Black Iron Pipe.

Really? I thought I read it was ok. I went with it because the black is such a mess and it rusts. I will have to research that. Is it galvanized on the inside too?

Well I just read multiple posts on this and there is no conclusive evidence I can find. One said ok for natural gas but never for propane, another said the opposite, one said it can flake of and clog orifice, another said this is not n issue anymore... I'm not worried about it. Looks better than black, won't rust, no problems thus far. If I have a clog then I will switch it out...bd2xu said:Really? I thought I read it was ok. I went with it because the black is such a mess and it rusts. I will have to research that. Is it galvanized on the inside too?

Well I just read multiple posts on this and there is no conclusive evidence I can find. One said ok for natural gas but never for propane, another said the opposite, one said it can flake of and clog orifice, another said this is not n issue anymore... I'm not worried about it. Looks better than black, won't rust, no problems thus far. If I have a clog then I will switch it out...

Yeah, chances are you will be %100 fine! I shot mine with a clear coat. I figured could not hurt anything and might help with the rust..

I had my first failure this weekend, it would appear that the gas valve controller has failed. I was heating up struck water when I noticed that the burner was off, I reset the system and no joy, my troubleshooting has verified that the PID is working and that the the controller is receiving 24vac, still the igniter is not sparking. The controllers are throwaways, at $65.00, but it could be the gas valve, more troubleshooting will confirm that.

Good thing I have an old turkey fryer, still used the PID for temps readings and of course the pumps still functioned, so I had a successful brew day ending with 5 gallons of ferment able wort for what should be a Very tasty APA.

Good thing I have an old turkey fryer, still used the PID for temps readings and of course the pumps still functioned, so I had a successful brew day ending with 5 gallons of ferment able wort for what should be a Very tasty APA.

Okay a little update to this....

Im using a Honeywell intermittent pilot retrofit kit, included in the kit was a new controller 8610u and gas valve plus install instructions.

I measured 28 VAC from the transformer so i decided to replace the igniter, that did not fix the problem but i did end up using a better igniter pilot setup so at least i made and improvement. More troubleshooting revealed no power to the gas valve, based on that I'm replacing the controller and the transformer. Im replacing the transformer since its putting out 28VDC rather than 24 VAC, not that i think that would kill the controller but....i also verified that the grounds are good and set-up per the instructions.

My concern is that the controller failed only after about 15 hours of use, what have I done wrong? The PID is set to on/off mode so i know it's not cycling too much, also i followed the install instructions for the controller. Perhaps its time to start gathering parts to convert to electric as I've spent over $100.00 in parts to fix my current setup.

Im using a Honeywell intermittent pilot retrofit kit, included in the kit was a new controller 8610u and gas valve plus install instructions.

I measured 28 VAC from the transformer so i decided to replace the igniter, that did not fix the problem but i did end up using a better igniter pilot setup so at least i made and improvement. More troubleshooting revealed no power to the gas valve, based on that I'm replacing the controller and the transformer. Im replacing the transformer since its putting out 28VDC rather than 24 VAC, not that i think that would kill the controller but....i also verified that the grounds are good and set-up per the instructions.

My concern is that the controller failed only after about 15 hours of use, what have I done wrong? The PID is set to on/off mode so i know it's not cycling too much, also i followed the install instructions for the controller. Perhaps its time to start gathering parts to convert to electric as I've spent over $100.00 in parts to fix my current setup.

Similar threads

- Replies

- 1

- Views

- 520

- Replies

- 3

- Views

- 977

- Replies

- 3

- Views

- 611