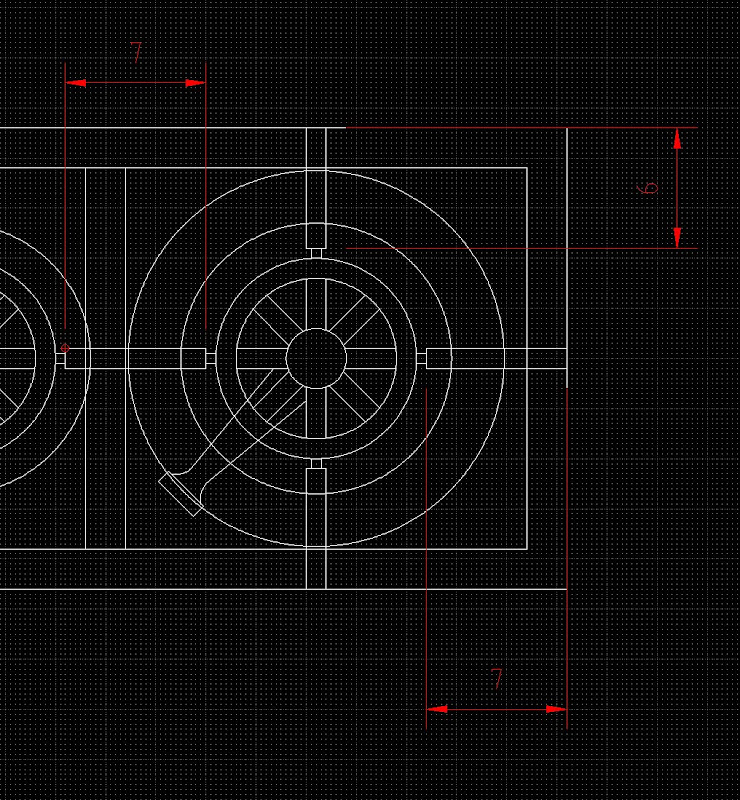

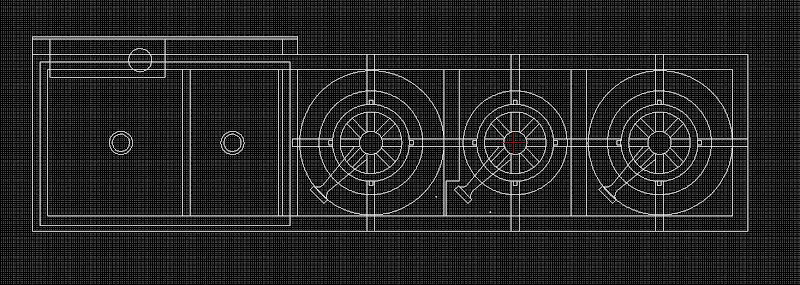

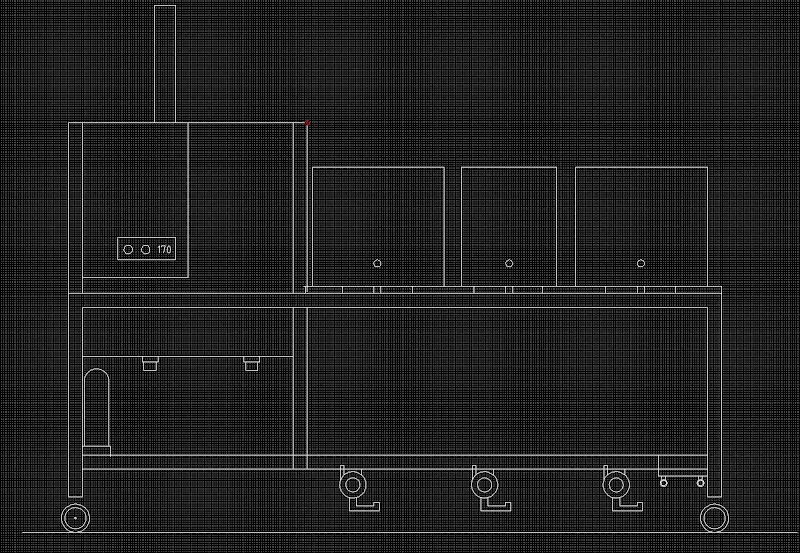

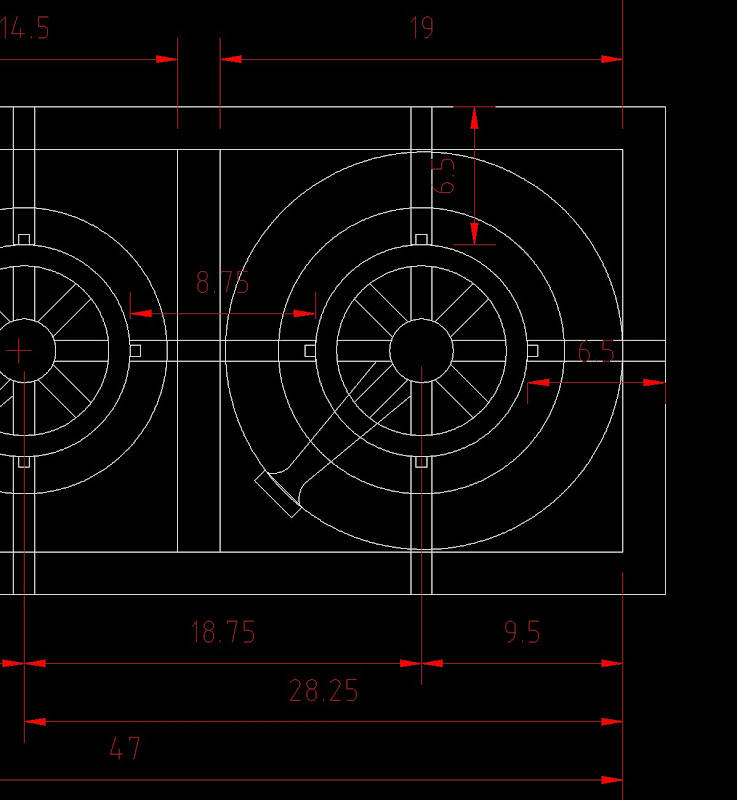

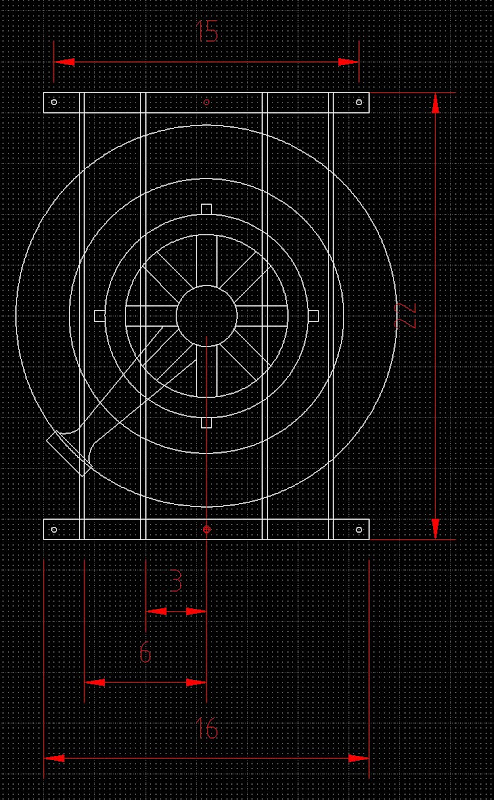

Grill design, shown with the 11 and 20.5 gallon kettles sitting on top.

The up and down bars are 3/16" x 1" stainless welded on side.

The cross wise bars are 1/8" x 1" stainless laid flat.

The grills are held in place on the stand by 4 or 6 1/4" bolts.

I'm a bit worried about the bars warping with heat from the burner, but so what if they do a bit ?

I thought about making these out of mild steel, but then they would be a rust mess.

I'll have about an 1.25" between the top of my burner and the underside of the pot. That is about the same spacing as on the gas stove we have in our house.

I'm hoping that running the grill bars longwise will allow good air flow around the underside of the pot. The flame won't go outside of the bars at +/- 6", but there isn't a lot I can do about that.

I've tried to minimize the amount of grill bar that gets heated directly by the flame to minimize the amount of heat not going onto the pot and the amount of heat coming back to the frame.

The pots never touch the 2x2 frame, so the frame is not conducting heat away from the pots. I dislike designs that put the pots directly on the frame because usually the frame is cold relative to the flame and pot and the frame is usually impeding the air/flame flow.

I'm not sure I like this design.

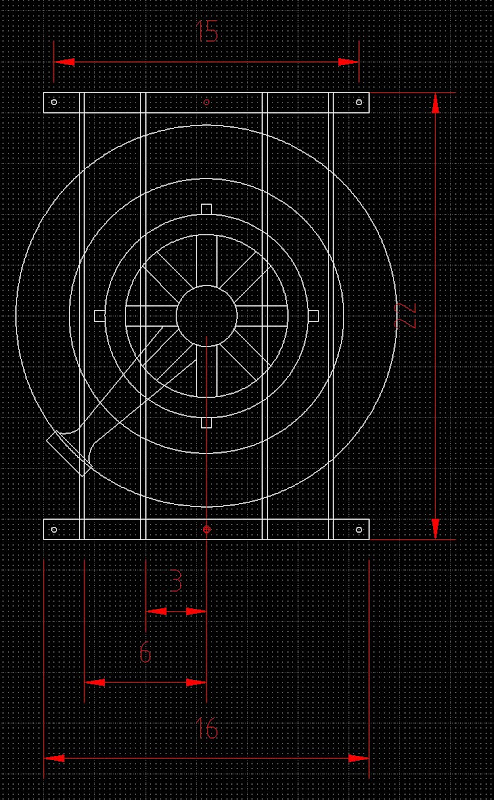

The up and down bars are 3/16" x 1" stainless welded on side.

The cross wise bars are 1/8" x 1" stainless laid flat.

The grills are held in place on the stand by 4 or 6 1/4" bolts.

I'm a bit worried about the bars warping with heat from the burner, but so what if they do a bit ?

I thought about making these out of mild steel, but then they would be a rust mess.

I'll have about an 1.25" between the top of my burner and the underside of the pot. That is about the same spacing as on the gas stove we have in our house.

I'm hoping that running the grill bars longwise will allow good air flow around the underside of the pot. The flame won't go outside of the bars at +/- 6", but there isn't a lot I can do about that.

I've tried to minimize the amount of grill bar that gets heated directly by the flame to minimize the amount of heat not going onto the pot and the amount of heat coming back to the frame.

The pots never touch the 2x2 frame, so the frame is not conducting heat away from the pots. I dislike designs that put the pots directly on the frame because usually the frame is cold relative to the flame and pot and the frame is usually impeding the air/flame flow.

I'm not sure I like this design.