You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Closed-system pressurized fermentation technique!

- Thread starter WortMonger

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

They are good for estimating finishing fermentation, but you need to get a hydro sample to get good numbers. They work great before fermentation starts though.

splendidus

Well-Known Member

First could you tell us about your process? I have been using pressure but have yet to get a good process. Interested on what is working for you.

Now to your questions, you problem is the beer is likely 68F which means it will be very hard to pour without foam. Going from high pressure to low the CO2 will want to rush out of solution. This is only heightened as your get warmer. Other than cooling do the beer to 34F or going from high pressure to high pressure you will likely get foam.

Actually now that I think about it, if you used the method for filling bottles from a picnic tap (under pressure) then poured that sample to your measuring device it should work!

Basically I ferment in a 5 gal corny and use a 3 gal corny as an airlock/blow-off collector. I have a spunding valve built per the instructions in this thread attached to the 3 gal keg's gas in port. When I want to take a sample I unhook the blow-off tube connected to the gas in of the 5 gal corny. I then hook up a picnic tap to the liquid out of the 5 gal and fill a couple of mugs with foam. I then wait for the foam to subside and fill my hydro tube with beer and let it sit over night before taking the reading. I drink the remaining beer, which isn't horribly under-carbonated. I just would prefer not having to settle foam to fill the test tube. I thought there might have been a clever solution out there.

EDIT: After taking a sample, I purge the 3 gal keg and only then reattach the 5 gal keg. This avoids sucking sanitizer back into the fermenter.

They are good for estimating finishing fermentation, but you need to get a hydro sample to get good numbers. They work great before fermentation starts though.

+1. After fermentation begins the refractometer never agrees with the hydrometer reading. It's close but not reliable. I built an air lock from a water filter housing and cutoff part of a sanke dip tube. Being able to watch the bubbling allows me to gauge where the fermentation is at so I usually only take one sample before cold crashing to make sure I'm at or below the final gravity I'm expecting.

View attachment 1425755663998.jpg

View attachment 1425755689331.jpg

+1. After fermentation begins the refractometer never agrees with the hydrometer reading. It's close but not reliable.

Please.......!!!

Basic science and math.

Yes, you do need to have the pre-ferment reading, and a calculator (beersmith has a tool for this) but my comparison with hydrometer is spot on.

To take a reading that uses almost 1% of your product, requires you to degas the sample is bordering on Luddite.

Sorry, but get with the program.

Tom

To take a reading that uses almost 1% of your product, requires you to degas the sample is bordering on Luddite.

I am with the program. I use beersmith as well but it is never spot on. The refractometer reading is usually off by a few points from the hydrometer. After spending 12 years of brewing in carboys taking samples with a hydrometer multiple times, I don't think my current process of taking 1 sample is ludicrous.

Brewing 10.5 gallon batches and ending up with 2 5 gallon kegs of beer is just fine with me. Not bothered about the half gallon that goes to waste. Just call me a typical wasteful American.

Crane:

Sorry, was not intending to bash anyone.

Just I think a refractometer is such a great thing. After you calibrate it you should be great.

If I am curious I can take a few readings during the mash, one preboil, during boil, post boil and a couple of times when topping up the fermenter to make sure I hit OG.

Then to watch the speed of fermenter with several tests out of a picnic tap and then the final test of the finished beer.

All this would only use a few ounces of product with no cooling/heating/degassing.

Bottom line, the best and cheapest step I have taken.

Tom

Sorry, was not intending to bash anyone.

Just I think a refractometer is such a great thing. After you calibrate it you should be great.

If I am curious I can take a few readings during the mash, one preboil, during boil, post boil and a couple of times when topping up the fermenter to make sure I hit OG.

Then to watch the speed of fermenter with several tests out of a picnic tap and then the final test of the finished beer.

All this would only use a few ounces of product with no cooling/heating/degassing.

Bottom line, the best and cheapest step I have taken.

Tom

+1. .....I built an air lock from a water filter housing and cutoff part of a sanke dip tube.....

Crane

Great idea!

Do you find it "cleans" the co2 as it bubbles through the water?

I am dabbling into harvesting the co2 and looking at filtering techniques.

Tom

Crane

Great idea!

Do you find it "cleans" the co2 as it bubbles through the water?

I am dabbling into harvesting the co2 and looking at filtering techniques.

Tom

I'm not sure how to measure that. I have not had issues with my PRV guming up except for once when I had liquid get pushed threw it, but from other people's experience I though I would try this to prevent it. On my last 5 gallon batch I forgot to add in ferm-cap and my 7.5 gallon sanke overflowed into the airlock adding about a cup or so blow off into it. That would have been a lot worse of a mess to clean up if I didn't have this airlock.

FredTheNuke

Well-Known Member

U can use a digital refractometer accurately (with a correction equation)

Crane had me worried that my readings were off.....

So I mixed up a sugar solution and my hydrometer and refractometer matched.

Then I grabbed a recent brew and did the same.

The hydrometer almost drove me crazy with the co2 and the sticking to the sides.

After playing with it for several minutes I got a reading that I judged to be accurate. Took a couple drops and put in the refractometer and the reading matched what Beersmith said it should.

Not to dis anyone who wants to stick with a hydrometer, but I do not see any advantage other than $20. (And I have broken enough hydrometers to pay for a refractometer is short order)

Especially if you are pressure fermenting and have to deal with co2 this is the way to go.

(I was forced due to environmental regulations to process the almost half a bottle needed for this test.)

Tom

So I mixed up a sugar solution and my hydrometer and refractometer matched.

Then I grabbed a recent brew and did the same.

The hydrometer almost drove me crazy with the co2 and the sticking to the sides.

After playing with it for several minutes I got a reading that I judged to be accurate. Took a couple drops and put in the refractometer and the reading matched what Beersmith said it should.

Not to dis anyone who wants to stick with a hydrometer, but I do not see any advantage other than $20. (And I have broken enough hydrometers to pay for a refractometer is short order)

Especially if you are pressure fermenting and have to deal with co2 this is the way to go.

(I was forced due to environmental regulations to process the almost half a bottle needed for this test.)

Tom

Ok I think I have my setup ready to use! I too had a housing water filter available and decided to plumb it in. Also I added a ball lock liquid post on the out side so I can hook up jumpers to cornets and also hook up a single tap faucet to take samples from. Hopefully this will all work and not have any issues. Thanks! Hope this works!!

View attachment ImageUploadedByHome Brew1426615030.172304.jpg

View attachment ImageUploadedByHome Brew1426615057.138616.jpg

View attachment ImageUploadedByHome Brew1426615030.172304.jpg

View attachment ImageUploadedByHome Brew1426615057.138616.jpg

I have started to use this fermentation method for my last 5 or so batches, and I have yet to look back. My best beers have come from this technique (though there have been other factors that may have also contributed to that). Nonetheless, this makes things so much simpler, and the pressure levels inhibit yeast off-flavors that would occur from my higher fermentation temps (high 70's). Pressure transfering helps with oxidation prevention, easier on my back not having to lift heavy 5 gallon carboys around, and partial/full carbonation in the primary :rockin:

Thank you wortmonger and all else who have contributed to this thread!

Thank you wortmonger and all else who have contributed to this thread!

I told ya so,  lol. It doesn't make better beer, it just makes making beer better... to me that is! I hope more continue to try this method and continue to improve upon it. Thank you all for contributing to this thread and technique.

lol. It doesn't make better beer, it just makes making beer better... to me that is! I hope more continue to try this method and continue to improve upon it. Thank you all for contributing to this thread and technique.

Anyone ever kill their yeast with too much pressure?

Background: I have been pressure fermenting for almost two years with great success (thanks Wortmonger). On my current batch of Porter, a broken sanke coupler caused the gas side to not engage. I didn't know there was an issue until it started pushing beer out the sample port through the picnic tap. Switched couplers and he keg was at 60+ psi. I brought the temp up a few degrees and lowers the pressure hoping to restart fermentation. Fast forward a few days and it still seems stalled (refract reading the same). I am degassing a sample for a hydro.

Any thoughts?

Background: I have been pressure fermenting for almost two years with great success (thanks Wortmonger). On my current batch of Porter, a broken sanke coupler caused the gas side to not engage. I didn't know there was an issue until it started pushing beer out the sample port through the picnic tap. Switched couplers and he keg was at 60+ psi. I brought the temp up a few degrees and lowers the pressure hoping to restart fermentation. Fast forward a few days and it still seems stalled (refract reading the same). I am degassing a sample for a hydro.

Any thoughts?

Add fresh yeast?

I finally got my pressurized fermentation system working. I have a hefeweizen under pressure right now. Looking at the carbonation charts, I should be at 60 psi for this beer at fermentation temp. Seems high to me. Any suggestions?

Edit: Here's a picture of my set up:

Edit: Here's a picture of my set up:

Homebeerbrewer:

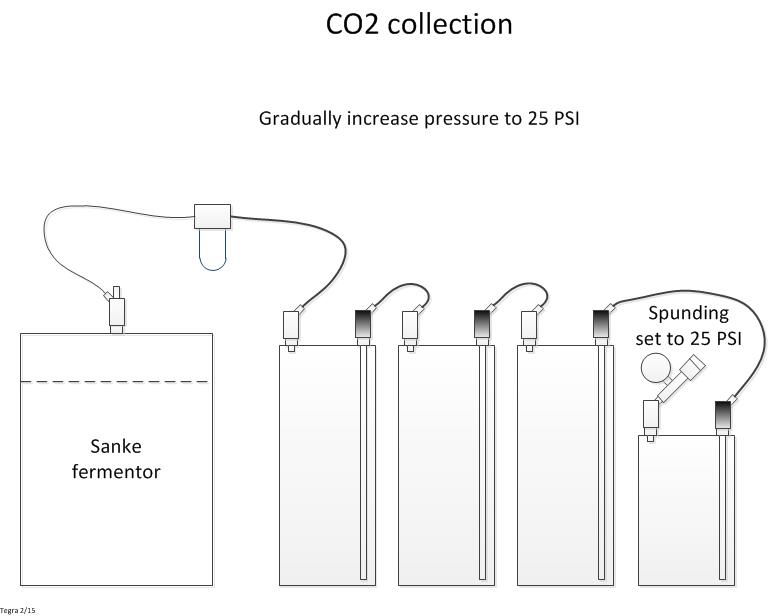

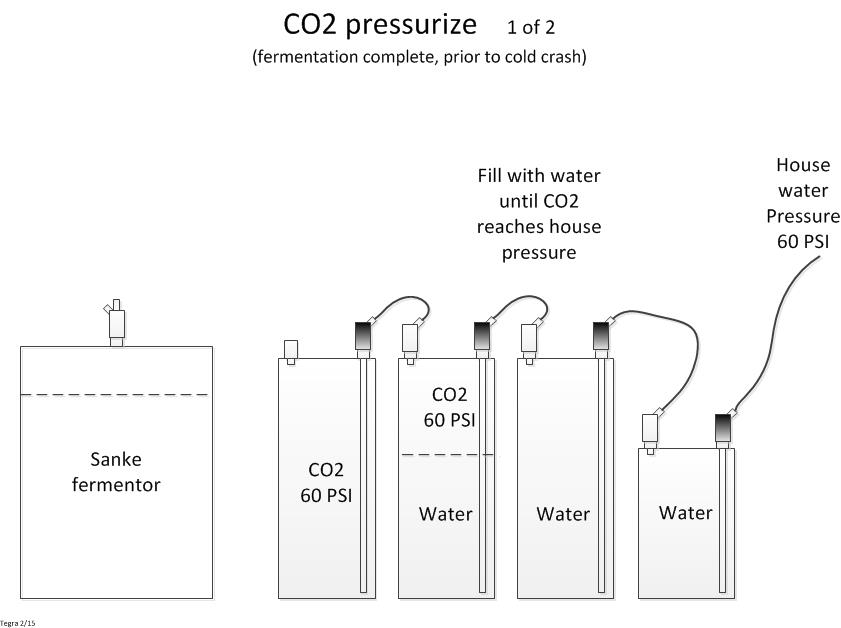

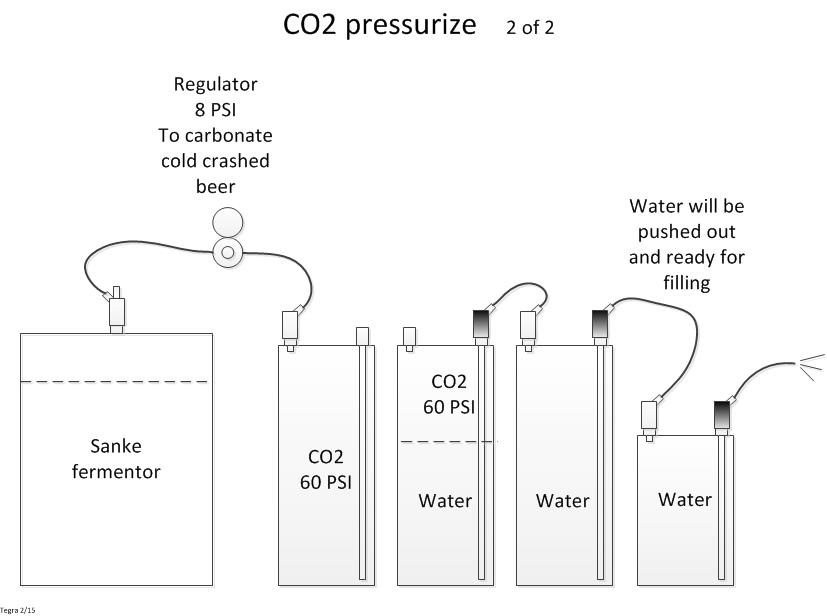

If you get about 20psi in the head of the keg by the time you are done that should be about right.

By that time the beer will have some co2 dissolved and when you drop the temperature (close to freezing) the beer will begin to absorb the 20psi and the pressure will drop to below 10 in a few days.

This may not get you full carbonation but at least more than half done.

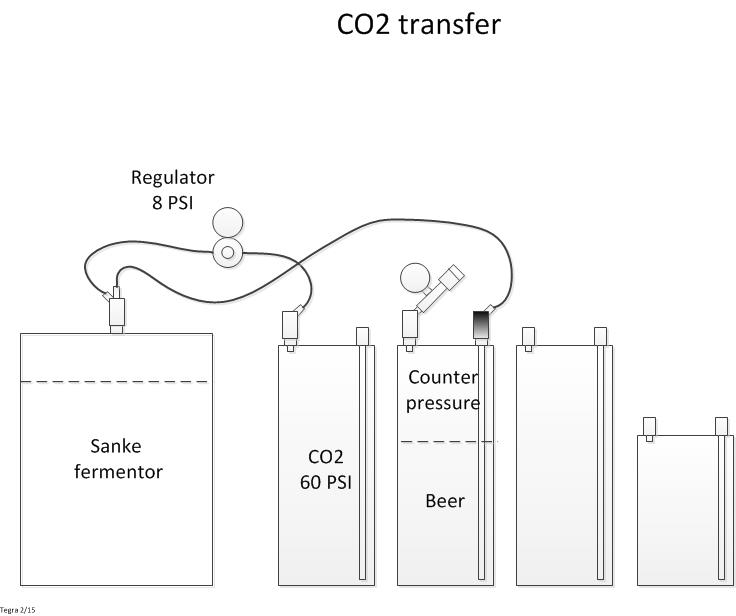

(I have a separate corny that I store the co2 in and then hook up during cooling, with a regulator set to about 8 psi to finish carbonating)

Tom

If you get about 20psi in the head of the keg by the time you are done that should be about right.

By that time the beer will have some co2 dissolved and when you drop the temperature (close to freezing) the beer will begin to absorb the 20psi and the pressure will drop to below 10 in a few days.

This may not get you full carbonation but at least more than half done.

(I have a separate corny that I store the co2 in and then hook up during cooling, with a regulator set to about 8 psi to finish carbonating)

Tom

Homebeerbrewer:

If you get about 20psi in the head of the keg by the time you are done that should be about right.

By that time the beer will have some co2 dissolved and when you drop the temperature (close to freezing) the beer will begin to absorb the 20psi and the pressure will drop to below 10 in a few days.

This may not get you full carbonation but at least more than half done.

(I have a separate corny that I store the co2 in and then hook up during cooling, with a regulator set to about 8 psi to finish carbonating)

Tom

What does the addition of a corny keg do?

I believe the corny is basically inline between the fermenter and the spunding valve to store CO2 that can be recycled for use to add pressure back to the fermented/carbonating beer or be used to help pressure transfer from one container to the next or whatever else you would want to do with it. Essentially it would be 'free' CO2What does the addition of a corny keg do?

I finally got my pressurized fermentation system working. I have a hefeweizen under pressure right now. Looking at the carbonation charts, I should be at 60 psi for this beer at fermentation temp. Seems high to me. Any suggestions?

Edit: Here's a picture of my set up:

What is the purpose of the blow off tube and water jug after the spunding valve? I would not expect fermentation blowoff to make it through the spunding valve without clogging it and creating a pressure bomb. I have already gone through one of those same valves from having some sticky wort flow through it.

On another note I see that some of you using the tri clamp setup instead of the stock sanke dip tube don't have a secondary safety pressure valve. Not the safest approach IMHO. One of the advantages of going with the sanke dip tube is that all sanke couplers have a 60 psi safety relief valve built into them.

Thanks Tegra, I have it at 20 psi now.

As far as having the jug after the spunding valve, I guess I should rethink my setup. I saw the filter canister idea, so I may have to incorporate that into my setup. I have tried the sanke dip tube and coupler, but it didn't work for me. I got krausen into the spunding valve, and when I kegged the beer, I picked up a ton of yeast. I decided to go with the tri clamp setup instead. Using the tri clamp, I'm not too concerned about krausen reaching the spunding valve since I do 10 gallon batches.

But, there's always that chance.

Back to the drawing board...

As far as having the jug after the spunding valve, I guess I should rethink my setup. I saw the filter canister idea, so I may have to incorporate that into my setup. I have tried the sanke dip tube and coupler, but it didn't work for me. I got krausen into the spunding valve, and when I kegged the beer, I picked up a ton of yeast. I decided to go with the tri clamp setup instead. Using the tri clamp, I'm not too concerned about krausen reaching the spunding valve since I do 10 gallon batches.

But, there's always that chance.

Back to the drawing board...

1MadScientist

Well-Known Member

I am not following what you do. Is this a corny you have inline between the fermenter(s) and spunding valve?(I have a separate corny that I store the co2 in and then hook up during cooling, with a regulator set to about 8 psi to finish carbonating)

Tom

Pictures would help if it is something different.

MS

Mad scientist:

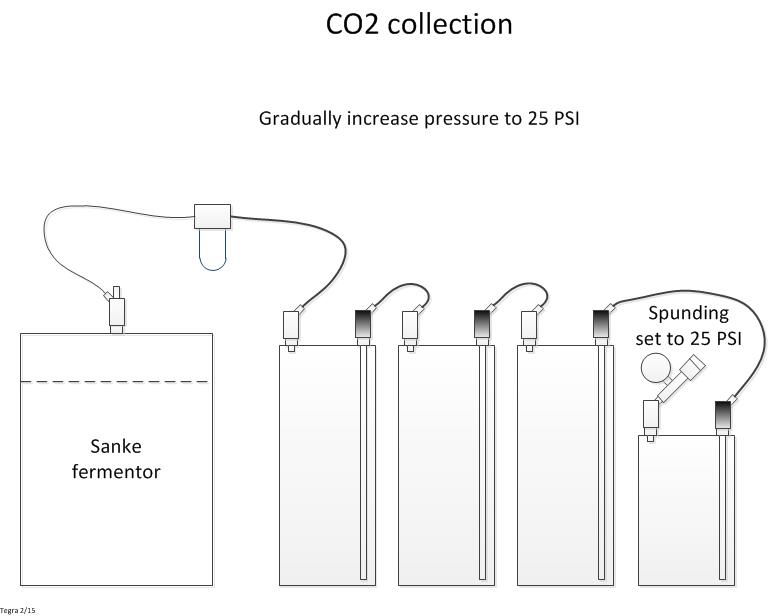

It was actually you that got me started on this! (With your photo of your dedicate co2 corny)

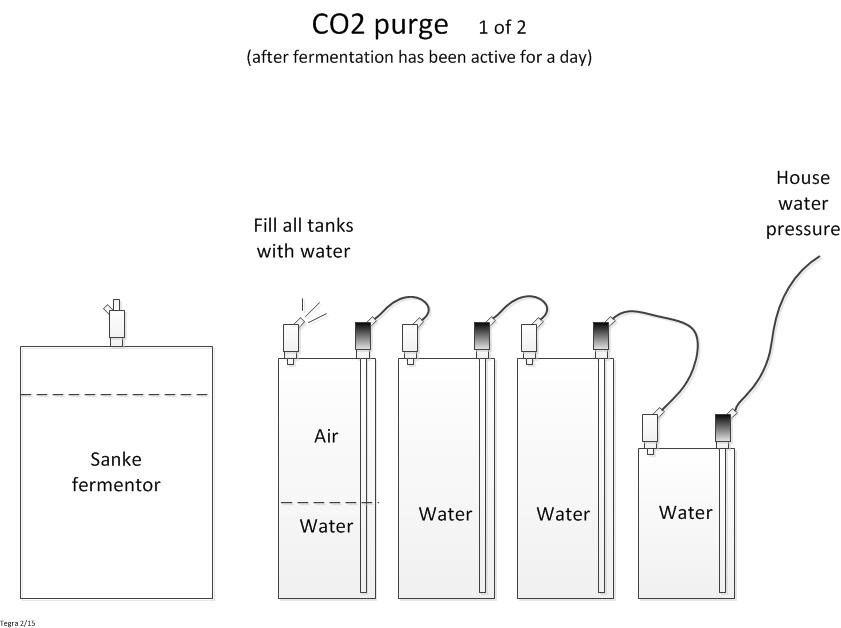

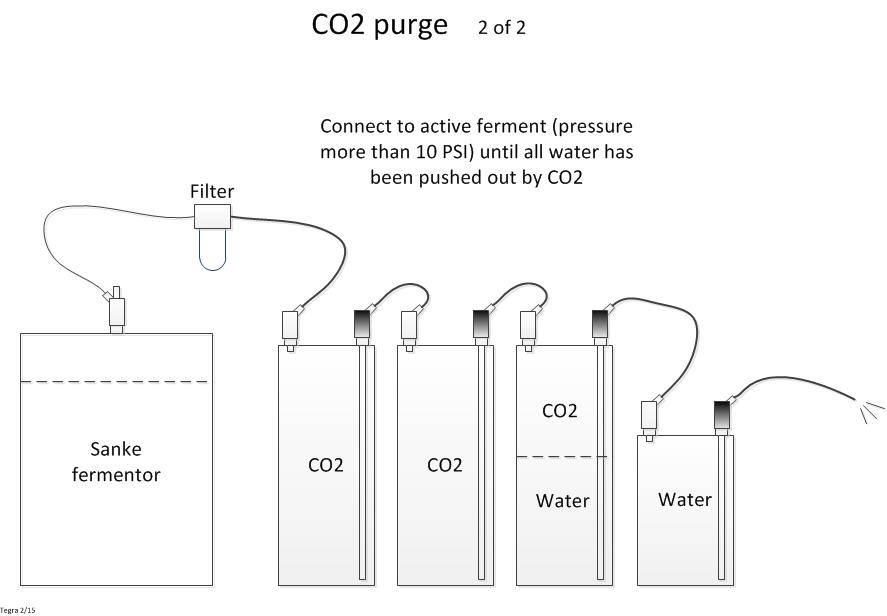

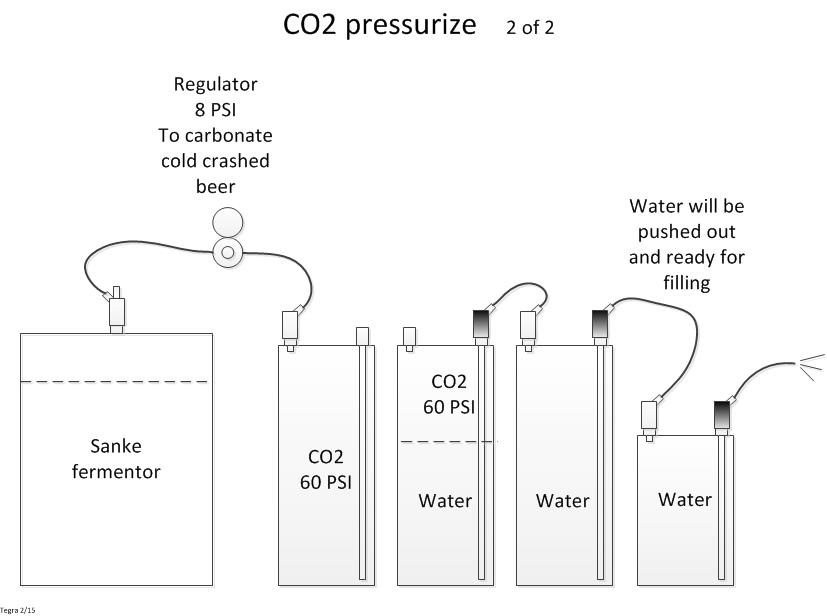

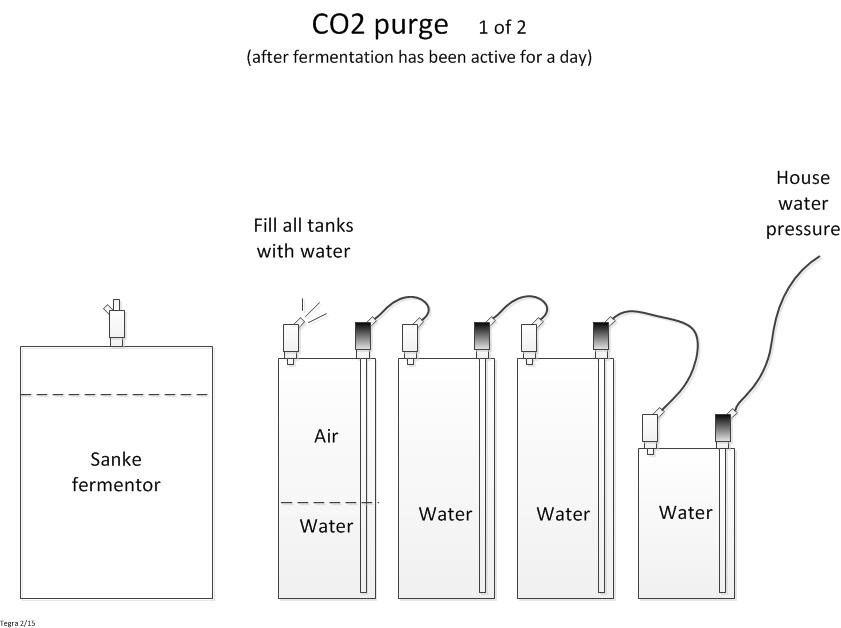

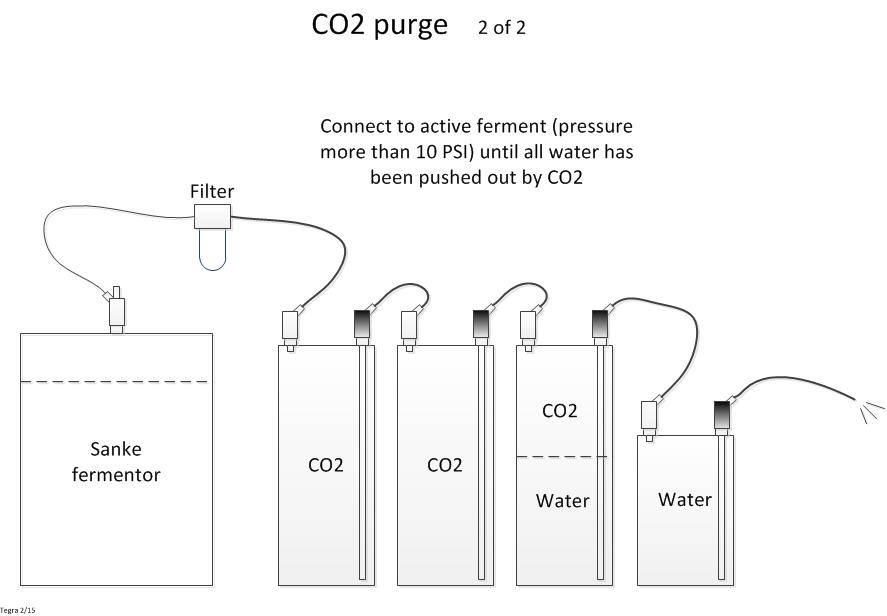

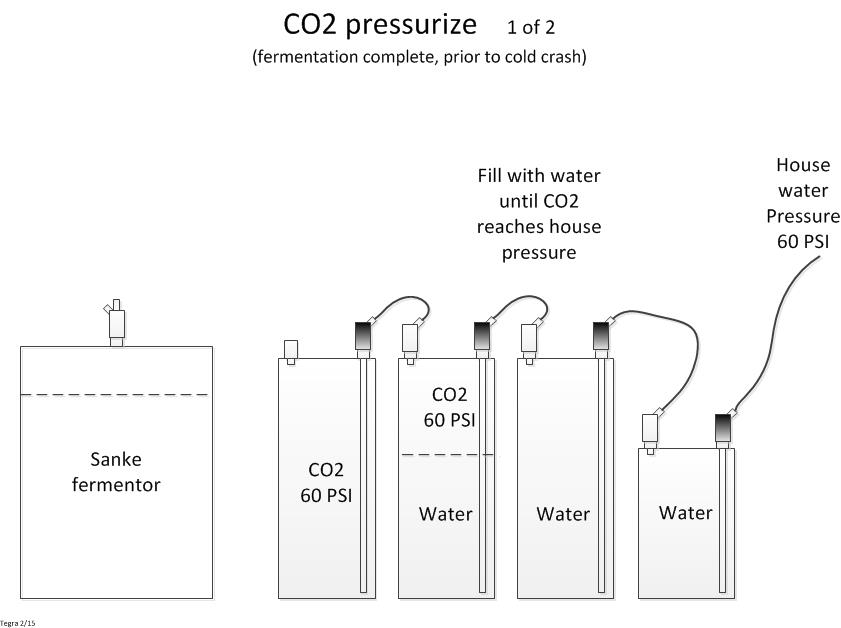

I have since been inspired by oldfart over on brewboard to try harvesting in several corny kegs in series, and the. Compressing with tap water pressure.

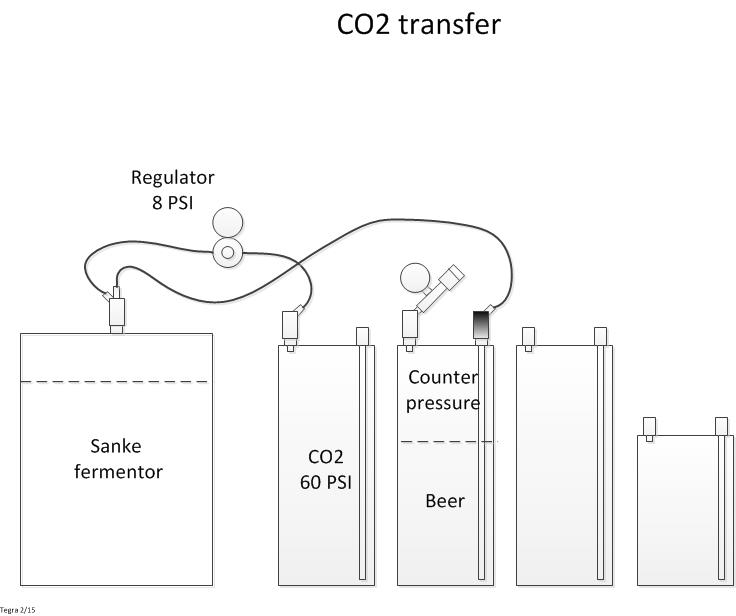

This gives me enough co2 to carbonate and transfer from the fermenting Sanke to my three serving kegs.

(I like to put the crazy in mad)

Tom

It was actually you that got me started on this! (With your photo of your dedicate co2 corny)

I have since been inspired by oldfart over on brewboard to try harvesting in several corny kegs in series, and the. Compressing with tap water pressure.

This gives me enough co2 to carbonate and transfer from the fermenting Sanke to my three serving kegs.

(I like to put the crazy in mad)

Tom

This was all developed by "Oldfart" over at brewboard.com over 10 years ago.

They thought him mad for even thinking about doing this. It seems he soon after disappeared, so maybe he was?

(Would love to get in touch with him)

This is what I have been playing with for the last few brews....

- Sanke is in a chest freezer with the co2 pipe going through the wall.

- I have been brewing about a 12 gallon batch.

- The small keg is a 3 gallon I bottle from and reuse for the next batch

- Fermcap is necessary to prevent blowoff

Tom

They thought him mad for even thinking about doing this. It seems he soon after disappeared, so maybe he was?

(Would love to get in touch with him)

This is what I have been playing with for the last few brews....

- Sanke is in a chest freezer with the co2 pipe going through the wall.

- I have been brewing about a 12 gallon batch.

- The small keg is a 3 gallon I bottle from and reuse for the next batch

- Fermcap is necessary to prevent blowoff

Tom

I could use some help with a simple question about this process. I went through the first 200 posts and cannot find a clear answer. I'm using 5 gal. corny kegs, ten gallon batches and plan to put the wort into three kegs.

I will put a spunding valve on the gas-in post. Leave it furment under pressure and here is where I get confused.

My current batches produce a fair amount of trub. I can't see how I can take a sample or transfer the beer through the small out post without completely clogging it. Or is that even an issue? I've seen comments that you have to draw off a couple pints to get to clear beer, but I haven't seen anyone say anything about problems getting the beer out. Does the trub actually just flow through the small out post?

I also see some are cutting their dip tubes shorter to avoid the trub, but then others say this isn't necessary.

Apologies if this has been covered, but if you can, what's the scoop?

I will put a spunding valve on the gas-in post. Leave it furment under pressure and here is where I get confused.

My current batches produce a fair amount of trub. I can't see how I can take a sample or transfer the beer through the small out post without completely clogging it. Or is that even an issue? I've seen comments that you have to draw off a couple pints to get to clear beer, but I haven't seen anyone say anything about problems getting the beer out. Does the trub actually just flow through the small out post?

I also see some are cutting their dip tubes shorter to avoid the trub, but then others say this isn't necessary.

Apologies if this has been covered, but if you can, what's the scoop?

I don't use Corny's, but I'll try to answer your question...

I think you're going to have problems with what you've described. Spunding through the gas post may clog, and could over-pressure and kill your yeast.

Using the standard dip tube will clog too. Some guys use a shortened dip tube without control of how deep the dip tube is into the trub.

What may work for you is replacing the stock pressure relief valve (assuming you have one) with a specially made spunding valve, and then go with a shortened dip tube.

What I would do though, is get a second Corny lid and adapt it specially for fermenting.

Use a compression fitting with rubber o-rings like the ones that Bobby sells, and a ss racking cane that can slide up and down to control the depth of the cane, and also a NPT spud that you can screw an adjustable pressure relief valve into as a spunding valve.

I think you're going to have problems with what you've described. Spunding through the gas post may clog, and could over-pressure and kill your yeast.

Using the standard dip tube will clog too. Some guys use a shortened dip tube without control of how deep the dip tube is into the trub.

What may work for you is replacing the stock pressure relief valve (assuming you have one) with a specially made spunding valve, and then go with a shortened dip tube.

What I would do though, is get a second Corny lid and adapt it specially for fermenting.

Use a compression fitting with rubber o-rings like the ones that Bobby sells, and a ss racking cane that can slide up and down to control the depth of the cane, and also a NPT spud that you can screw an adjustable pressure relief valve into as a spunding valve.

JuanMoore

Getting the banned back together

I could use some help with a simple question about this process. I went through the first 200 posts and cannot find a clear answer. I'm using 5 gal. corny kegs, ten gallon batches and plan to put the wort into three kegs.

I will put a spunding valve on the gas-in post. Leave it furment under pressure and here is where I get confused.

My current batches produce a fair amount of trub. I can't see how I can take a sample or transfer the beer through the small out post without completely clogging it. Or is that even an issue? I've seen comments that you have to draw off a couple pints to get to clear beer, but I haven't seen anyone say anything about problems getting the beer out. Does the trub actually just flow through the small out post?

I also see some are cutting their dip tubes shorter to avoid the trub, but then others say this isn't necessary.

Apologies if this has been covered, but if you can, what's the scoop?

Only the trub right next to the bottom of the diptube will get sucked up. After the transfer you will be able to see a small area around the diptube where the yeast cake is gone, somewhere between the size of a dime and a quarter depending on the strain of yeast and how compact the yeast cake is. While I prefer using sankey's, I've done over a dozen 10 gal batches split between 2 corny kegs with full length untrimmed diptubes. Out of those I've only had a clog one time, and it was with a highly flocculant yeast that I let ferment for 2 months, and then cold crashed for 3 days.

And it's not a couple of pints of yeast, it's more like a couple ounces of yeasty stuff, and then it flows perfectly clean. I remove the QD at the far end of my transfer line and put it in an empty pint glass, connect the QD on the other end to the fermenter, turn the gas on, and then remove the QD attached to the fermenting keg as soon as it starts running clear. Usually only fills the pint glass 1/3 way. Then I screw the line back on to the QD, connect one end to the receiving keg, and the other to the fermenter which starts the transfer. The last few ounces at the bottom of the keg will also pull a lot of yeast up, but I'm usually able to pull one of the QD's off before much makes it into the serving keg.

I don't use Corny's, but I'll try to answer your question...

I think you're going to have problems with what you've described. Spunding through the gas post may clog, and could over-pressure and kill your yeast.

Using the standard dip tube will clog too. Some guys use a shortened dip tube without control of how deep the dip tube is into the trub.

Good point, but splitting 10 gal between 3 kegs should leave enough headroom to avoid clogging the spunding valve. I usually fill mine to the brim and either use fermcap, or more frequently connect the spunding valve to a blowoff vessel rather than directly to the gas post of the fermenter keg.

As for the diptube clogging during transfer, I've only experienced that once out of over two dozen kegs using full length diptubes.

I could use some help with a simple question about this process. I went through the first 200 posts and cannot find a clear answer. I'm using 5 gal. corny kegs, ten gallon batches and plan to put the wort into three kegs.

I will put a spunding valve on the gas-in post. Leave it furment under pressure and here is where I get confused.

My current batches produce a fair amount of trub. I can't see how I can take a sample or transfer the beer through the small out post without completely clogging it. Or is that even an issue? I've seen comments that you have to draw off a couple pints to get to clear beer, but I haven't seen anyone say anything about problems getting the beer out. Does the trub actually just flow through the small out post?

I also see some are cutting their dip tubes shorter to avoid the trub, but then others say this isn't necessary.

Apologies if this has been covered, but if you can, what's the scoop?

Just a thought, and I may be imagining it wrong, but you could possibly get away with removing the poppit from the post you are venting gas from (for the spunding valve), or drawing your samples from. That way you would remove that bottleneck where hop debris and trub can be problematic. Another thing that could work, would be to fill the cornies evenly(or 3.5-4 gal in 2 of them, the rest in the third), then jumper them together gas to beer posts and spund from only the gas post on one end, this way any venting co2 from either of the other kegs will push the trub away from the beer diptubes(helps prevent clogging? though the one on the far end will not get this possible benefit). It probably will take longer to all settle out of the vent side kegs though.

This is all wild ass guessing on my part so grain of salt and all of that. Feel free to tell me I am wrong and why it won't work. There is the potential that it may drive off hop aromas by bubbling all that CO2 through up to two kegs.

I have a diagram of how I used to use cornys back on 1943...

https://www.homebrewtalk.com/showpost.php?p=6101543

Moved on to a single Sanke to get my quantity up and simplify things a bit. (Also to free up the kegs)

Fermcap is essential and I did get a couple plugged liquid tubes. (Easily solved by pushing some co2 back through the post)

Tom

https://www.homebrewtalk.com/showpost.php?p=6101543

Moved on to a single Sanke to get my quantity up and simplify things a bit. (Also to free up the kegs)

Fermcap is essential and I did get a couple plugged liquid tubes. (Easily solved by pushing some co2 back through the post)

Tom

Thanks for all the tips. I'm going to assemble some parts and give it a try. Tegra's drawing is helpful. As is typcial, I'll probably come up with my own wild ass design and go from there. That's the fun of this hobby,

OnNe more question . . . what is the best way to oxegenate the wort before (or when) you put it into the fermenter. Right now I either shake the glass carboy or run small pump with a stone on the end inserted into the wort.

1MadScientist

Well-Known Member

OnNe more question . . . what is the best way to oxegenate the wort before (or when) you put it into the fermenter. Right now I either shake the glass carboy or run small pump with a stone on the end inserted into the wort.

I'm a roller

2/16/2013 by Mad Scientist Brewhaus, on Flickr

2/16/2013 by Mad Scientist Brewhaus, on FlickrMS

OnNe more question . . . what is the best way to oxegenate the wort before (or when) you put it into the fermenter. Right now I either shake the glass carboy or run small pump with a stone on the end inserted into the wort.

The pump with stone is better than shaking a glass carboy. Read my story here.

Maybe the best way is to use pure oxygen. You can get the cheap oxygen tanks at just about any hardware store.

Maybe the best way is to use pure oxygen. You can get the cheap oxygen tanks at just about any hardware store.

That is what I use. I have a stone mounted to a tee on the output of my plate chiller. So I chill, oxygenate, and fill my fermentor at the same time.

I'm about to give this method a try.

The plan is to use a 2nd corney to make up for the lack of head space. (with fermcap) Should I seal everything up with co2 or let it naturally carb seal?

It depends on your kegs. All my corneys I bought used and need to be hit with at least 15psi while I pull up on the lid handle to get them to settle into position where they will seal. If I just close the lid and apply 10psi I will end up with a leak.

Now on the flip side, I also found that sealing the lids with 15psi and bleeding down to 5psi would maintain the seal, but all the beers I fermented in corneys didn't ferment as fast as I would normally get nor would I hit the final gravity I was expecting. I think this is because I was shocking and/or killing a bunch of the yeast with the sudden increase in pressure. I am now fermenting only in sanke kegs and am getting the fast finishing fermentations that are hitting the final gravities I'm expecting.

It depends on your kegs. All my corneys I bought used and need to be hit with at least 15psi while I pull up on the lid handle to get them to settle into position where they will seal. If I just close the lid and apply 10psi I will end up with a leak.

Ever try keg lube? I slap some of that on and close the lid, then pump CO2 in. Never have a leak.

Ever try keg lube? I slap some of that on and close the lid, then pump CO2 in. Never have a leak.

Yes. I have to use it every time. My kegs seem to be in much worse shape than others I've seen.

Similar threads

- Replies

- 13

- Views

- 625

- Replies

- 34

- Views

- 733

- Replies

- 8

- Views

- 1K