Brewpastor

Beer, not rocket chemistry

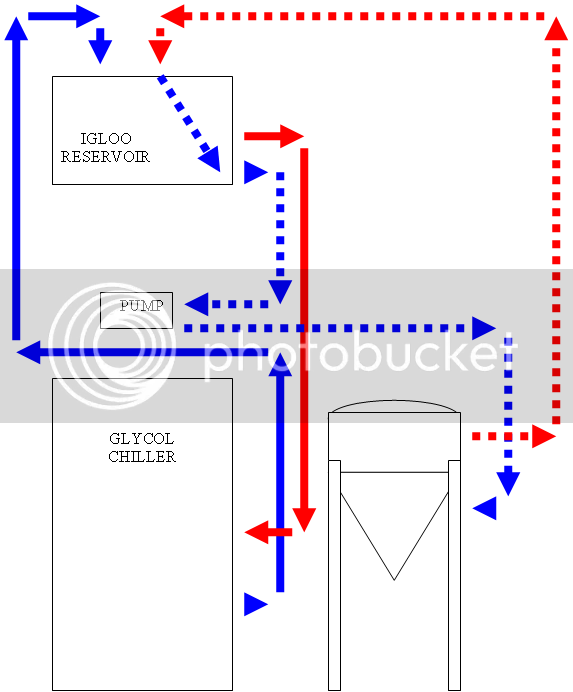

I need a tutorial. I want to use a solenoid valve on my fermenter. I have my gylcol chiller, which is designed as a beer line chiller. It chills the glycol and circulates it. Where do I go from here?

That's basically what I was picturing.I am not sure. the chiller has a recirc. pump, so I should probably figure out how to control the flow through the pump. This is not my strong suit. I had a set-up before that had the chiller maintaining a glycol reserve in a cooler which I then circulated from using a pump controlled by a ranco controller. But that seemed a little over-kill.

My brew buddy in NM had a similar setup. He used an ENTIRE chest freezer full of glycol to chill his jacketed conical for lagering.

What is on the cold side of the exchanger? How are you cooling it?

Enter your email address to join: