SchmidtyBeer

Well-Known Member

I have spent a lot of time following this forum and have been very inspired by many of your builds. I thought it was only fair that I document my build and answer any questions along the way. I will also be asking many questions myself!

So lets get started:rockin: Oh and sorry for the photos, they were all taken on my cell phone. I will try and get some better photos posted.

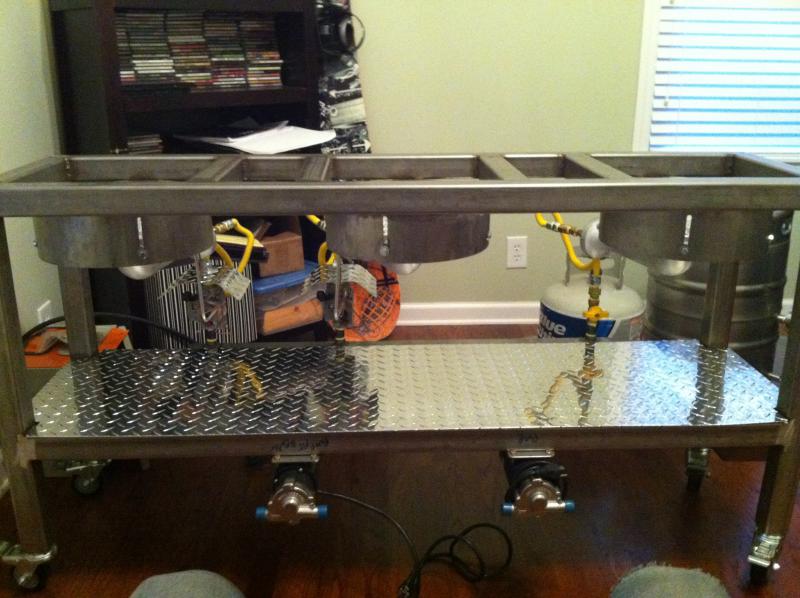

The stand welded with the pumps, chill plate, casters, and valves attached.

So lets get started:rockin: Oh and sorry for the photos, they were all taken on my cell phone. I will try and get some better photos posted.

The stand welded with the pumps, chill plate, casters, and valves attached.