The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

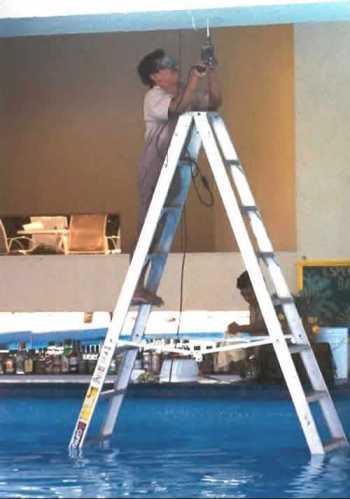

Its standard probably similar if not the same to yours. Im not too concerned at the moment because I only plan on doing 5 gal batches for the foreseeable future. If I were doing 10 gallon batches I would have to give beer away all the time to justify brewing as often as I like. Im not too concerned about boiling over. Also my element is on the far side from were I work with the system going and the keg has a separate ground and is gfci protected. I see how that could be an issue and didn't really think about the water tight factor so I might try to find some way to seal it up. Im glad I did it this way as I originally didn't have a plug on the end so it was hard wired to the box and I just changed the entire cord since I had like 4 of those laying around.

Pol do you think you could walk me through setting up the PID?

FWIW, I only do 5 gallon batches in my keggle, and I have boiled it over several times. Be careful with an element that is not water tight on the connections.

As for the PID, you said that you are using it in auto tune? For the mash? See, I only use my PID for boiling and therefore run it in manual mode for the boil. I have no experience using it in auto tune.

As for hops plugging the drain.... I have some pics in my gallery, I use those little SS scrubby pads that you can get at the store. They are like $1 for three in a package. I take one, tear it in half, and place it over my dip tube in my kettle. This way I can drain EVERYTHING from my kettle and still leave most of the gunk behind.

Do you have the SYL 2352 PID from Auber?

:rockin:

:rockin: