bbentley40

Well-Known Member

Ok guys.. I have lurked for a long time and only had a hand full of posts on the boards... but I figured this is a thread that I need to get going. I had thought about waiting to the end of my build and doing one big thread, but I just couldnt wait to share.

First, to give credit where it is due... Thanks to everyone who posts their ideas and pictures on this forum. I researched a lot, stole ideas from many (well.. I didnt really steal them since I am here to give them all back to the community with my own twist.. lol) and in the end came up with my design. I do have to give many thanks to Jester and Hoppopotomus because I probably used their threads the most to get ideas. And with that on to the pictures..

This is what I had to start with, its a 7.0cu ft GE that I got from Sams years ago. It is one of the few things I asked for in my divorce. My ex thought I was crazy, but I have been planning this for a LONG time.. lol. I had built a base for it already, thinking I would add to that for my Keezer build, but I scrapped it when I came up with my current idea. Oh and just another thing.. I am NOT a master craftsman by any stretch of the imagination (as you will be able to tell I am sure). I took 1 year of ag in high school because they made me.. the most woodworking experience I have is basically building a bird house.. lol.

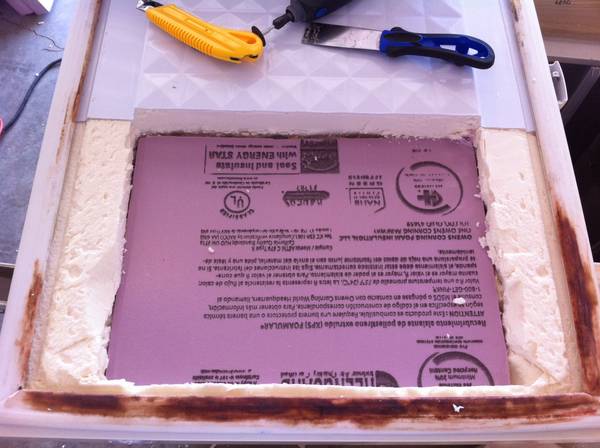

The new base:

Building up the walls:

And now test fitting the freezer (you cant see it in this picture, but I have a couple of 2x4s in place of what will eventually be the collar):

Now I know I said I am not master craftsman, but dont worry.. I didnt completely mismeasure the width of the base. You will see.

Here is a shot of the gap between the frame and the freezer. I plan to add a computer fan to help blow heat from the compressor out the back of the keezer.

I decided to go with Red Oak for the skin of my project. I just think it looks really good when it is stained. Here are the first boards going on:

First, to give credit where it is due... Thanks to everyone who posts their ideas and pictures on this forum. I researched a lot, stole ideas from many (well.. I didnt really steal them since I am here to give them all back to the community with my own twist.. lol) and in the end came up with my design. I do have to give many thanks to Jester and Hoppopotomus because I probably used their threads the most to get ideas. And with that on to the pictures..

This is what I had to start with, its a 7.0cu ft GE that I got from Sams years ago. It is one of the few things I asked for in my divorce. My ex thought I was crazy, but I have been planning this for a LONG time.. lol. I had built a base for it already, thinking I would add to that for my Keezer build, but I scrapped it when I came up with my current idea. Oh and just another thing.. I am NOT a master craftsman by any stretch of the imagination (as you will be able to tell I am sure). I took 1 year of ag in high school because they made me.. the most woodworking experience I have is basically building a bird house.. lol.

The new base:

Building up the walls:

And now test fitting the freezer (you cant see it in this picture, but I have a couple of 2x4s in place of what will eventually be the collar):

Now I know I said I am not master craftsman, but dont worry.. I didnt completely mismeasure the width of the base. You will see.

Here is a shot of the gap between the frame and the freezer. I plan to add a computer fan to help blow heat from the compressor out the back of the keezer.

I decided to go with Red Oak for the skin of my project. I just think it looks really good when it is stained. Here are the first boards going on: