I am not a diagrammer (nor an electrician), but if you want to take a crack at it I don't think it is that complex. Let's see if I can describe it somewhat clearly:

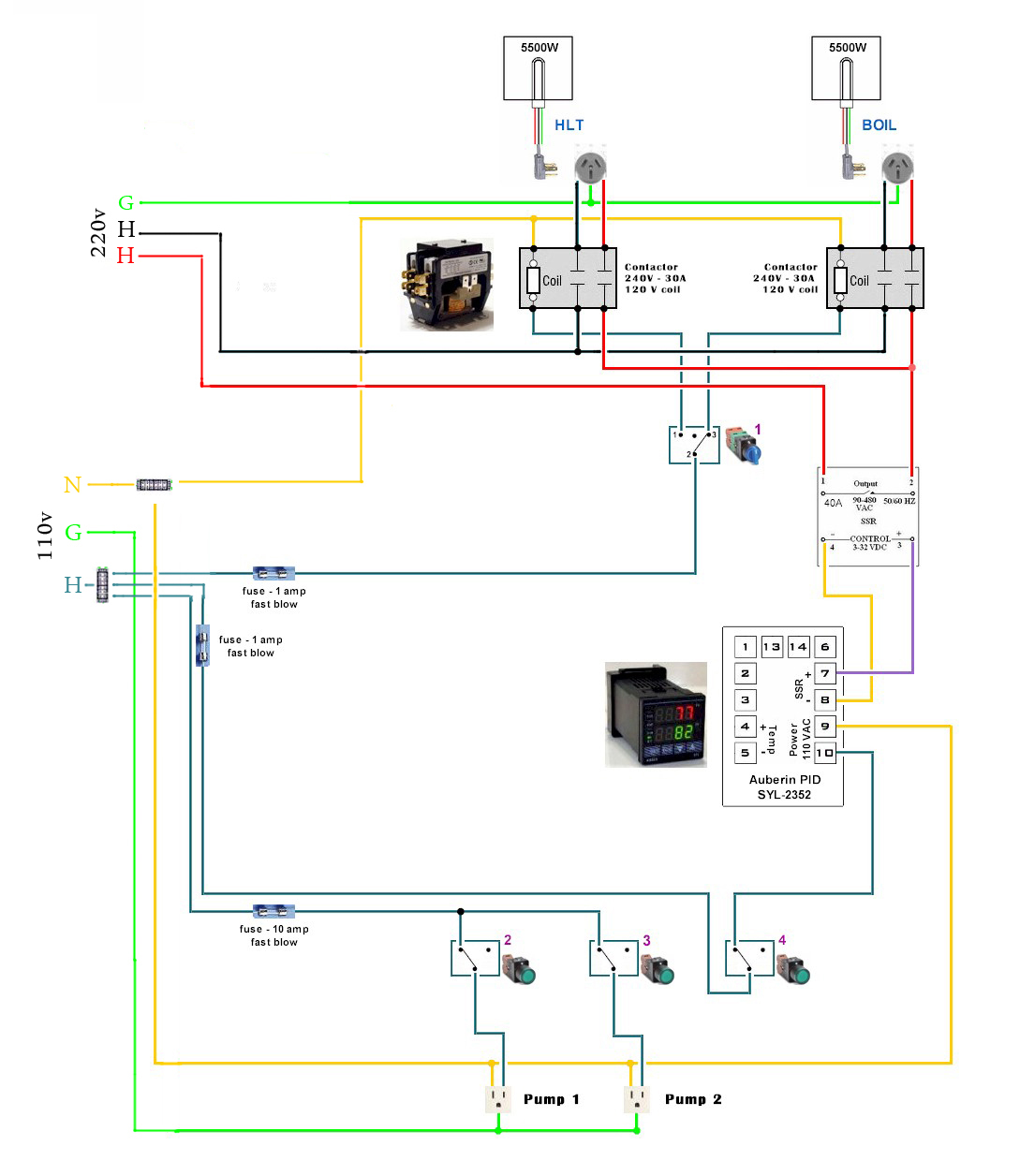

1) Where your 240v feed enters the panel, you don't have a neutral (you have H-H-G), so the yellow lines do not emerge from the 240v feed

2) You will add a 120v feed (from a GFCI outlet), with H-N-G, and the yellow lines will emerge from that neutral

3) You need another color because you have 3 Hots. Most of your devices are 120v, so fewer changes to the diagram if we change the blue H from the 240v feed to black where it really powers a 240v device. So from the 240v feed, change to black 6 lines (1 to each contactor (not the coil), 1 from each contactor to its outlet, and 1 from each outlet to its element)

4) From the 120v feed you added, show your hot as the remaining blue lines, and remove the blue line emerging from the 240v feed

5) For the ground on the 120v feed you added, take the lower green line shown coming out of the 240v feed, and move that so it emerges from the 120v feed

6) You will want to tie both of these grounds together where you connect it to your panel, assuming a metal panel

I think that does it, but you definitely should have someone more qualified bless it before building.

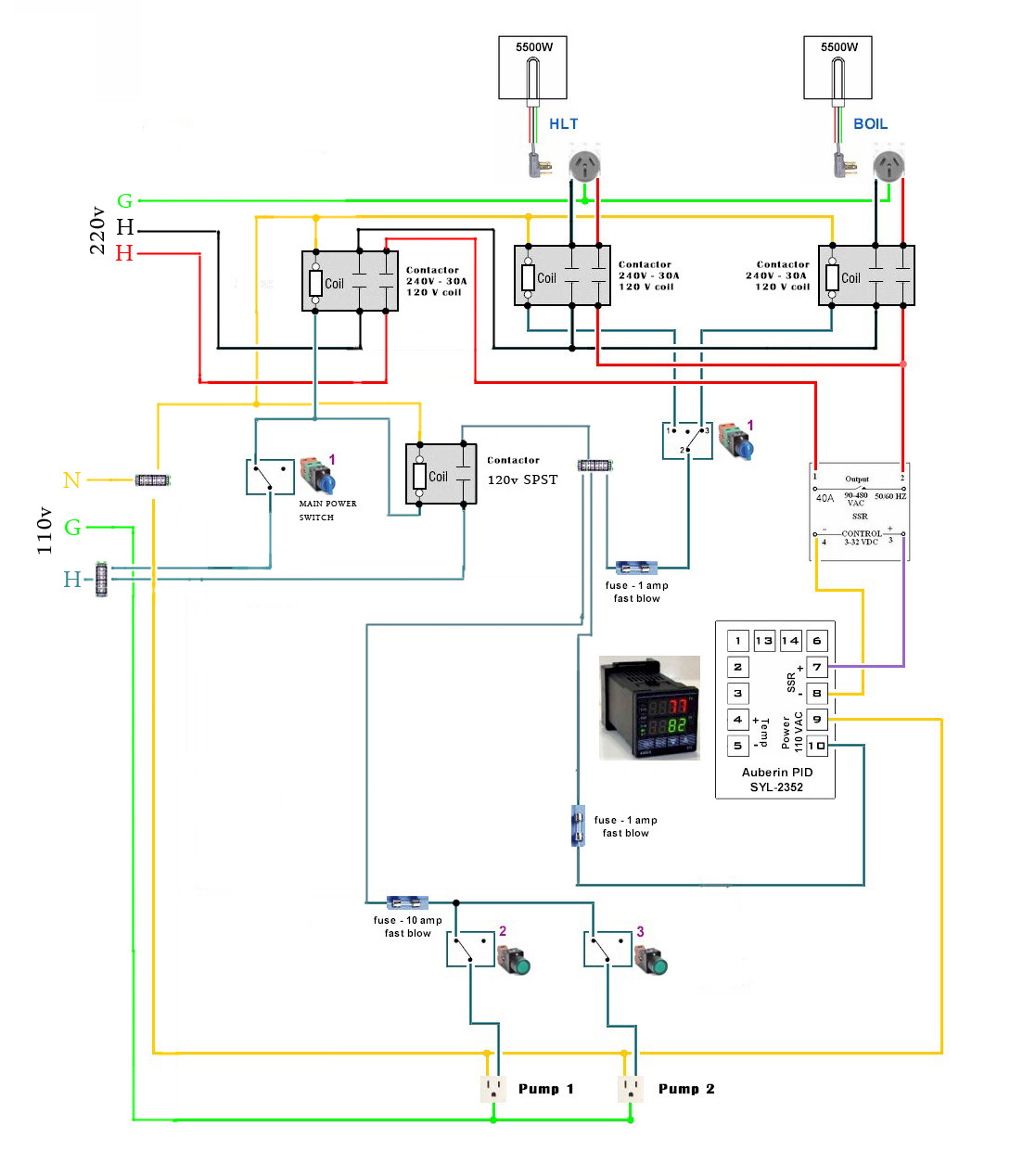

On another note, I would recommend that you have a way to turn off both power feeds in the panel, with a single switch (could be an e-stop switch if you like).

P-J does this with 240v by shunting a bit of current to ground and tripping the GFCI. You would need an equivalent setup for the 120v circuit, but that is way out of my league. In that configuration, hitting the e-stop trips the GFCIs so there is no power to the panel. There are plenty of arguments around that solution, but I will not get into them here.

The other option is to have another contactor, and have the main power switch control the 120v coil, and have the hot lines run through the contactor. In your application (3 hots), you would either need a triple pole, single throw contactor, or you could wire a DPST for the 240v hots and a SPST contactor for the 120v hot, with each coil wired 120v in parallel from the switch. In this configuration, when the switch is closed your contactors allow power to flow into the panel, when the switch is open it is the only thing in the panel that is energized. I favor this solution, and it would also allow you to remove the switch (4) that powers off the PID. The main switch would power up the panel, the PID would be on when the panel is on, and switches (1-3) allow you to control power to the elements and pumps.

I hope that helps.