peterfuse

Well-Known Member

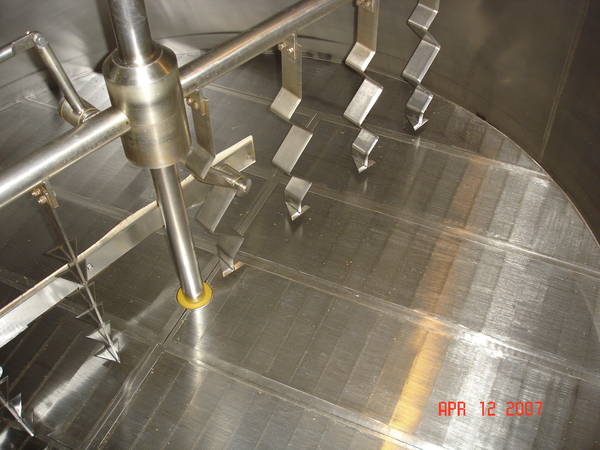

I'm just wondering how much wort a micobrewery boils at one time and how the hell they do it? all electric? I've only ever boiled as much as 6 gallons before.

Not really.Holy Crap that's a big boil. I would love to work in a microbrewery to see how all this is done properly.

Like in a huge mash tun how does the immense weight of the grain and water not cause a stuck mash all the time?

No, just the dimension are optimal.I guess this is done differently than in my little cooler.

Henry, what brewery is this?

OH you know, just a his modest setup in his garage.

OH you know, just a his modest setup in his garage.

By the look of those muttonchops, it's gotta be a commercial brewery.

Enter your email address to join: