neb_brewer

Well-Known Member

- Joined

- Apr 22, 2009

- Messages

- 108

- Reaction score

- 0

To start off, this isn't a how-to thread. The parts used for this build aren't available to everybody out there. I just want to show what weve come up with. It might inspire other similar systems.

With that said, I sure am lucky to have a father who is an electrical contractor. His overall construction know-how and handyman-ness have been invaluable in my brewing endeavors and advancements. I was even more lucky, when it was time to brew my first lager, that my father had done a TON of contract work for Johnson Controls. Over the years there have been some leftover parts from jobs that he has collected. We just barely had the parts needed to accomplish what we wanted for building our lagering chamber. In addition to the parts needed to build this, my dad also had to summon some deeply buried knowledge of program writing for the older control software used for this.

The foundation for the chamber:

An old GM fridge that weve had in the shop for years. Although not very energy efficient, it actually doesnt run very often to keep the beer at the desired temps.

Next, the controller pieces and parts (Im not going to go into detail about everything because like I said this isnt a how-to. Also, if you do have access to the things needed to build something similar to this, you probably can build it without somebody elses directions.) Basically, this turns the power to the fridge off/ based on the set temp.

The inside: There are two thermometers. One is attached to the carboy with insulation surrounding it to measure fermentation temperatures. This is the temperature that controls the on/off command for the fridge. The other thermometer is in the top right of the fridge and is just there to measure ambient temps.

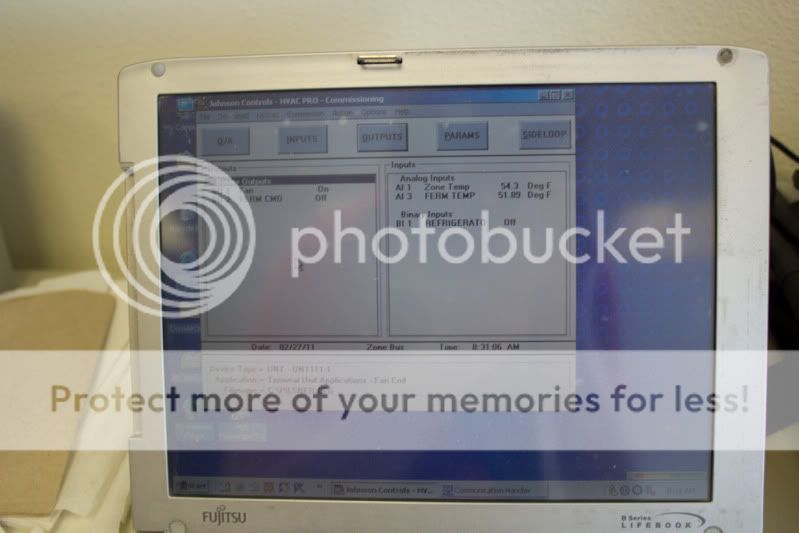

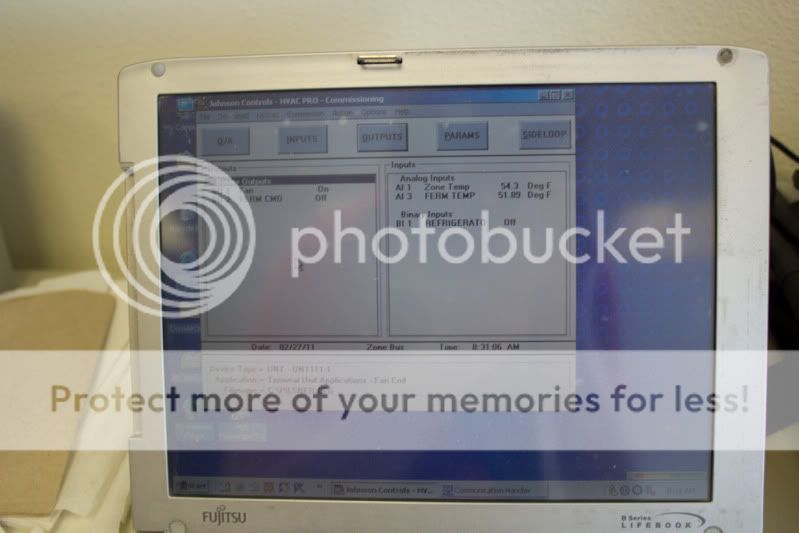

Last, but not least, is the computer. Its an old Fujitsu Lifebook running Windows 2000 that is upstairs on the office of the shop.

As you can see, the FERM TEMP is 51.89 (it was set at 52). The zone temp is at 54.4. The FERM CMD is the command that calls for the fridge to turn on/off based on the fermentation temperature. Since the FERM TEMP is at 51.89 the FERM CMD is off. The system is set to hold the fermentation temperature to within at least 1° although its always closer.

Weve done 3 lagers with this now and even though its not pretty it works great. Changing temps is as easy as changing it on the computer and hitting enter. We are considering adding a heating element. With that, we could set the fermentation temp for both lagers and ales and the computer would use both the heat and cooling to keep it at the desired temp. This would be handy for doing ales in the middle of winter when the temps around the shop arent conducive for them.

With that said, I sure am lucky to have a father who is an electrical contractor. His overall construction know-how and handyman-ness have been invaluable in my brewing endeavors and advancements. I was even more lucky, when it was time to brew my first lager, that my father had done a TON of contract work for Johnson Controls. Over the years there have been some leftover parts from jobs that he has collected. We just barely had the parts needed to accomplish what we wanted for building our lagering chamber. In addition to the parts needed to build this, my dad also had to summon some deeply buried knowledge of program writing for the older control software used for this.

The foundation for the chamber:

An old GM fridge that weve had in the shop for years. Although not very energy efficient, it actually doesnt run very often to keep the beer at the desired temps.

Next, the controller pieces and parts (Im not going to go into detail about everything because like I said this isnt a how-to. Also, if you do have access to the things needed to build something similar to this, you probably can build it without somebody elses directions.) Basically, this turns the power to the fridge off/ based on the set temp.

The inside: There are two thermometers. One is attached to the carboy with insulation surrounding it to measure fermentation temperatures. This is the temperature that controls the on/off command for the fridge. The other thermometer is in the top right of the fridge and is just there to measure ambient temps.

Last, but not least, is the computer. Its an old Fujitsu Lifebook running Windows 2000 that is upstairs on the office of the shop.

As you can see, the FERM TEMP is 51.89 (it was set at 52). The zone temp is at 54.4. The FERM CMD is the command that calls for the fridge to turn on/off based on the fermentation temperature. Since the FERM TEMP is at 51.89 the FERM CMD is off. The system is set to hold the fermentation temperature to within at least 1° although its always closer.

Weve done 3 lagers with this now and even though its not pretty it works great. Changing temps is as easy as changing it on the computer and hitting enter. We are considering adding a heating element. With that, we could set the fermentation temp for both lagers and ales and the computer would use both the heat and cooling to keep it at the desired temp. This would be handy for doing ales in the middle of winter when the temps around the shop arent conducive for them.