My house temperature fluctuates a lot during the day. My basement goes from 68 F to 56 F throughout the day. For the Ales i plan to brew during these cold months, I plan to make a temperature controlled chamber. At the moment I'm only focusing on heating the chamber. When spring comes I will setup up a cooling element too.

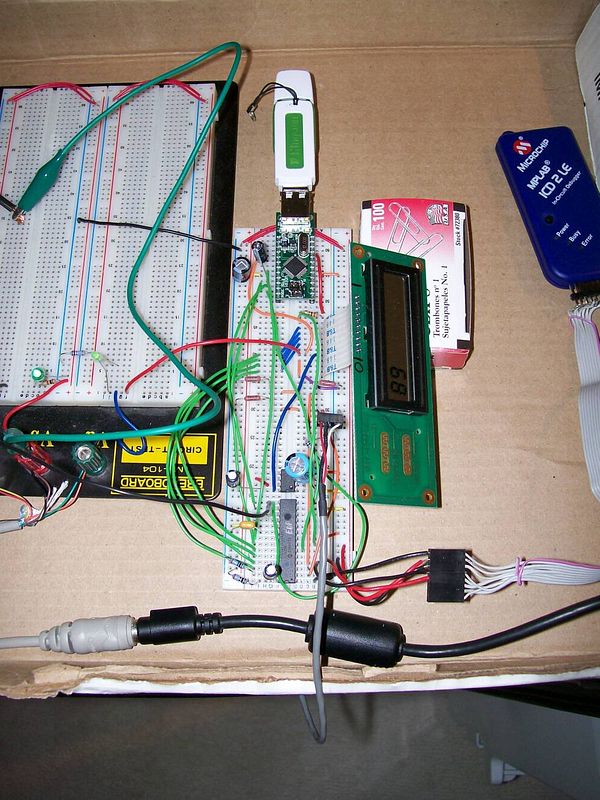

Coincidentally, I had all the pieces i needed lying around. The thermistor I used was a Vishay 2381 640 which is 10K ohm at 25 deg C. I used the PIC24FJ64GA002 micro controller. For logging temperatures, I used a VDIP1 module to write the temperatures and various other parameters to a USB thumb drive. I used a couple power resistors to generate around 18 watts of heat into the chamber. It's not a lot of heat, but I'm limited by the power supply I'm using. I also used an LCD to display the temperature.

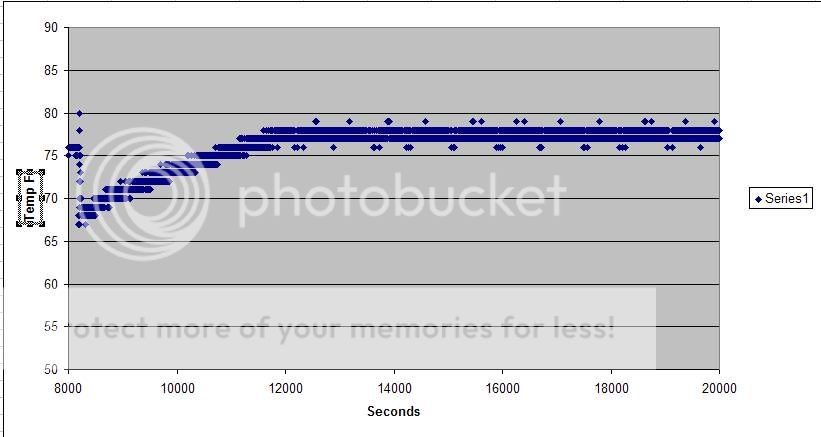

I stuck the heating component into a mini fridge, which is unfortunately too short for a carboy, but a plastic bucket will fit. The temperature range i picked was 76 - 79 deg F just for testing. The ambient temp was about 68.

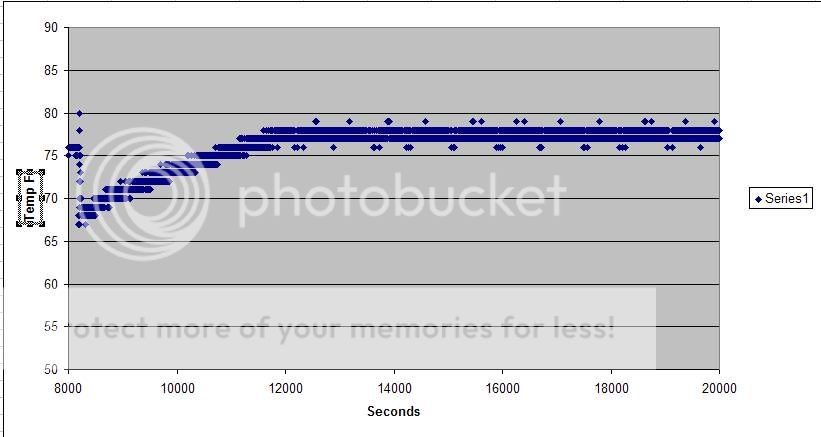

Here's the temps inside the mini fridge (mini fridge was unplugged):

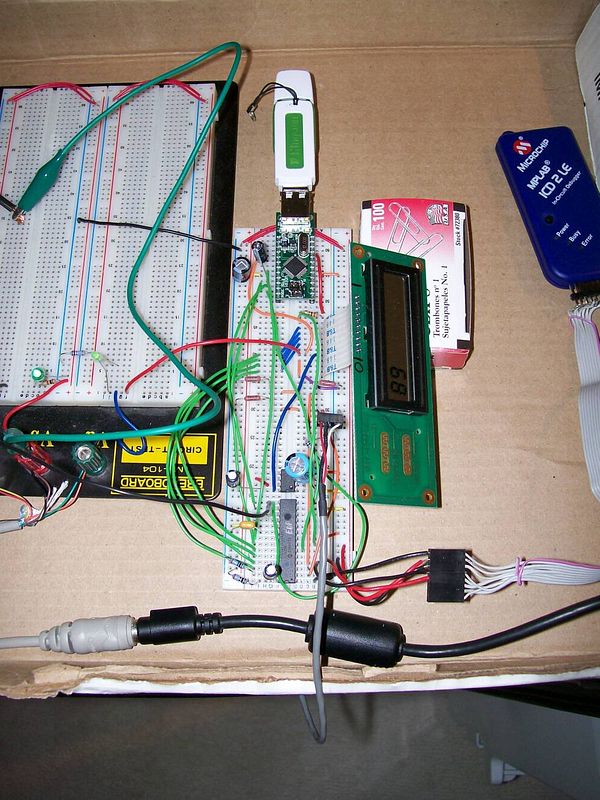

Here's the circuit in operation:

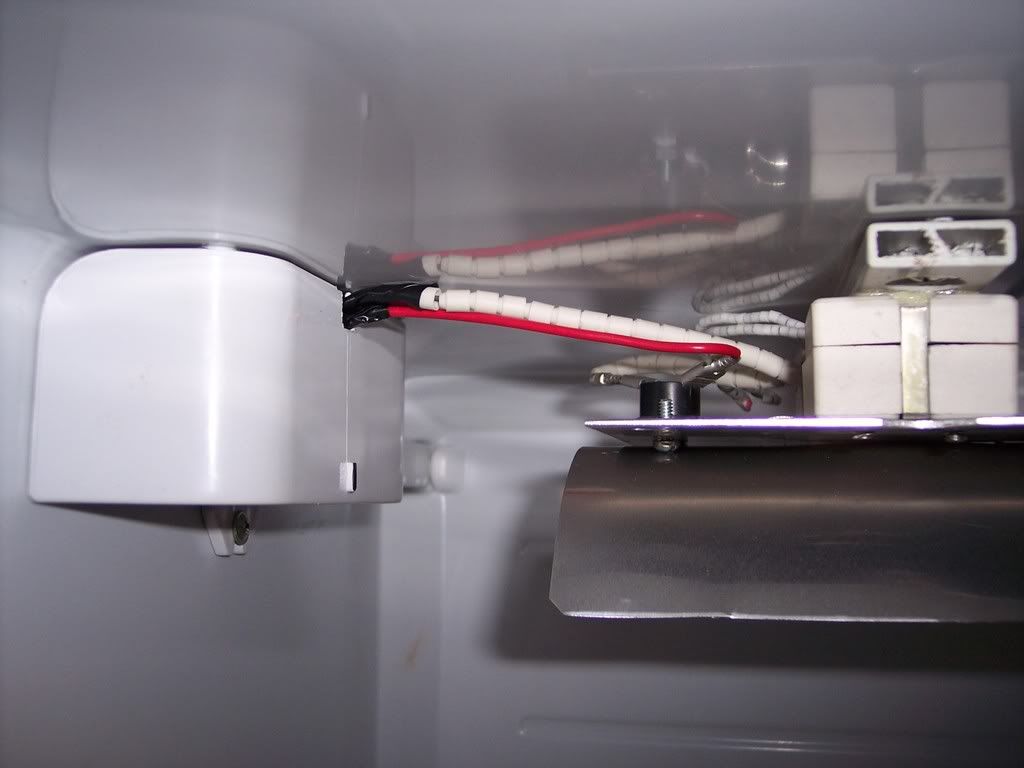

You can see the white ceramic power resistors inside. I used 4 of them so they don't get hot enough to be a fire hazard. Ideally, I would use a 100+ watt resistor strapped to a huge heat sink but i don't have one on hand. There's a small computer fan in there too to circulate the air and there's a FET switch transistor with a black heat sink. The grey wire coming over the top is the thermistor which is used to calculate the temperature.

Here the display shows 68 F because the door is open:

I'm using a 12v 2amp, 5v 2amp laptop power supply. The circuitry runs off 5v which is stepped to 3.3v with a regulator (LP2951). The 12v is solely for the heating resistors which is controlled with a transistor. It wouldn't be hard to replace the power resistors with a relay to switch on something more powerful.

Now i need to make a larger chamber to fit a glass carboy.

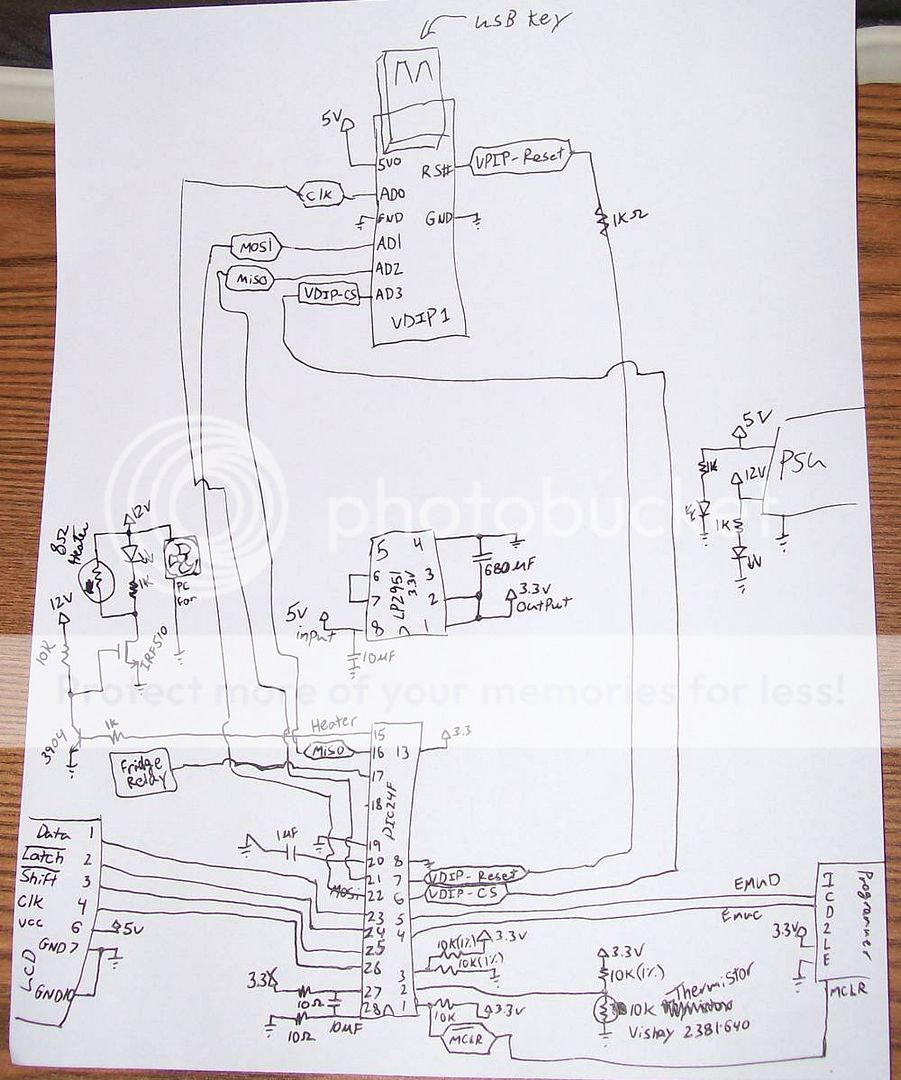

If anyone is interesting, I can post the firmware and schematic.

Coincidentally, I had all the pieces i needed lying around. The thermistor I used was a Vishay 2381 640 which is 10K ohm at 25 deg C. I used the PIC24FJ64GA002 micro controller. For logging temperatures, I used a VDIP1 module to write the temperatures and various other parameters to a USB thumb drive. I used a couple power resistors to generate around 18 watts of heat into the chamber. It's not a lot of heat, but I'm limited by the power supply I'm using. I also used an LCD to display the temperature.

I stuck the heating component into a mini fridge, which is unfortunately too short for a carboy, but a plastic bucket will fit. The temperature range i picked was 76 - 79 deg F just for testing. The ambient temp was about 68.

Here's the temps inside the mini fridge (mini fridge was unplugged):

Here's the circuit in operation:

You can see the white ceramic power resistors inside. I used 4 of them so they don't get hot enough to be a fire hazard. Ideally, I would use a 100+ watt resistor strapped to a huge heat sink but i don't have one on hand. There's a small computer fan in there too to circulate the air and there's a FET switch transistor with a black heat sink. The grey wire coming over the top is the thermistor which is used to calculate the temperature.

Here the display shows 68 F because the door is open:

I'm using a 12v 2amp, 5v 2amp laptop power supply. The circuitry runs off 5v which is stepped to 3.3v with a regulator (LP2951). The 12v is solely for the heating resistors which is controlled with a transistor. It wouldn't be hard to replace the power resistors with a relay to switch on something more powerful.

Now i need to make a larger chamber to fit a glass carboy.

If anyone is interesting, I can post the firmware and schematic.