Photopilot

Well-Known Member

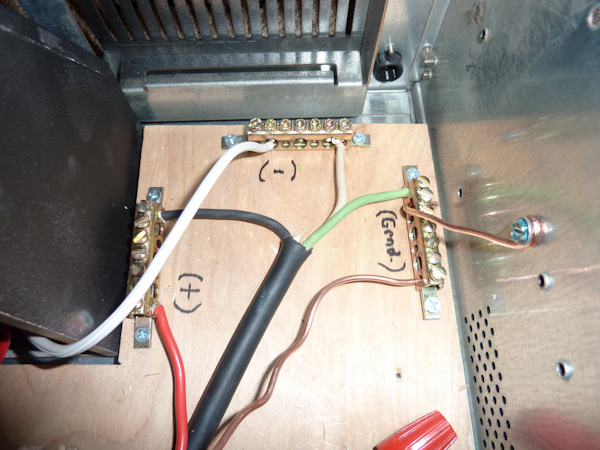

Here is the photo of my control panel. I just finished wiring it on Sunday in preparation of my first 10 gallon batch. I had been prepping water and the rest of my brewing equipment all morning, then when I plugged the panel in the GFCI popped immediately as did the CB in the panel and the inline fuse. I tried a number of times and each time the power went towards the element the CBs popped. I am wondering if it is anything to do with the wiring or is it a short in the element wiring. I changed plans and did a 10gallon all grain stove top brew. It made for a long day.

I am hoping for suggestions as to why the CB was popping so I can begin testing tonight.

I have a 3 wire feeding the 240/120 of a spa panel CB panel and the ground comes from a 120V GFCI from a different circuit that powers the PID only, as well as ground for the case and heating element circuit.

My heating element is potted in a PVC coupler. I attempted to put a ground wire screw into the base of the keg. I went through 4 batteries and broke a bit. I took the ground and used an alligator clip to ground the keg. I tested the ground on the plug attached to the element cord and there was continuity to the keg.

One other possible source is the inline fuse. I have a 12 gauge cord feeding the 4500W element. I could not find a slow burn fuse so i have a 20A fast burn fuse.

Now that the element is potted I am limited in testing or options. I will try testing continuity to the ground and OHMs of the element from the plug on the cord. What else should I look at?

I am hoping for suggestions as to why the CB was popping so I can begin testing tonight.

I have a 3 wire feeding the 240/120 of a spa panel CB panel and the ground comes from a 120V GFCI from a different circuit that powers the PID only, as well as ground for the case and heating element circuit.

My heating element is potted in a PVC coupler. I attempted to put a ground wire screw into the base of the keg. I went through 4 batteries and broke a bit. I took the ground and used an alligator clip to ground the keg. I tested the ground on the plug attached to the element cord and there was continuity to the keg.

One other possible source is the inline fuse. I have a 12 gauge cord feeding the 4500W element. I could not find a slow burn fuse so i have a 20A fast burn fuse.

Now that the element is potted I am limited in testing or options. I will try testing continuity to the ground and OHMs of the element from the plug on the cord. What else should I look at?