cmw6300

Well-Known Member

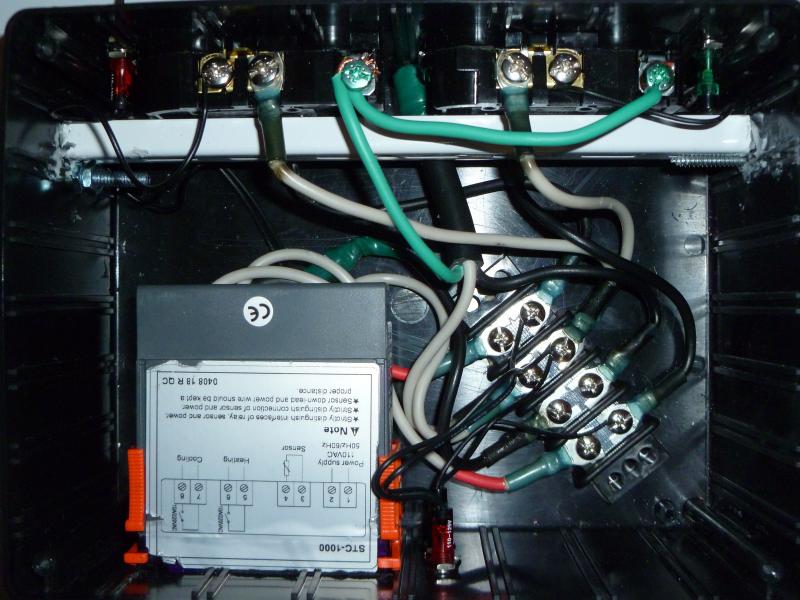

HI! I just picked them up out of the "Lamps" bin at radio shack when I got the project box. The red one is called a "Red Neon Lamp Assembly." Catalog Number: 272-712.

I wanted red for heating and blue for cooling, but they didn't have a blue one in this type or any other blue ones that I liked, so I got a green one and just pretend it's blue when it comes on.

Here's the Radio Shack link to the red one if you're interested. 120VAC Neon Lamp Assembly (2-Pack) - RadioShack.com

Excellent, thank you!