Ok, so here goes. - Mind you this is one of the first working machines from early on so visually it may differ from the final product.

I have been "burnt" by kickstarter & indiegogo campaigns in the past. The product wouldn't arrive or if it did it was no where near as amazing as had once been advertised.

The opposite can be said for the Brewie.

Back in last fall, I was completely new to brewing, had done a few 5 gallon batches with pots etc, but wanted something to automate just the cooking part to some extent. Obvioulsy I wanted the Speidel Braumeister. Especially because it had the fancy new screen. And at the same time, Brewie was on Indiegogo. It looked to good to be true, but after much debate, I pulled the trigger.

Today I saw it live.

The machine totally lives up to its expectations. The guy who did the demo with us, was so extremely open about everything - there was no question about any issue that he refused to ask. As a matter of fact he wanted to get as much feedback as possible from us and forward it to his team.

So this is how it went:

The hops are put in hops containers, not bags, and added to the hop compartments. These are still rough around the edges and could look nicer, but he said the new version was already in the works.

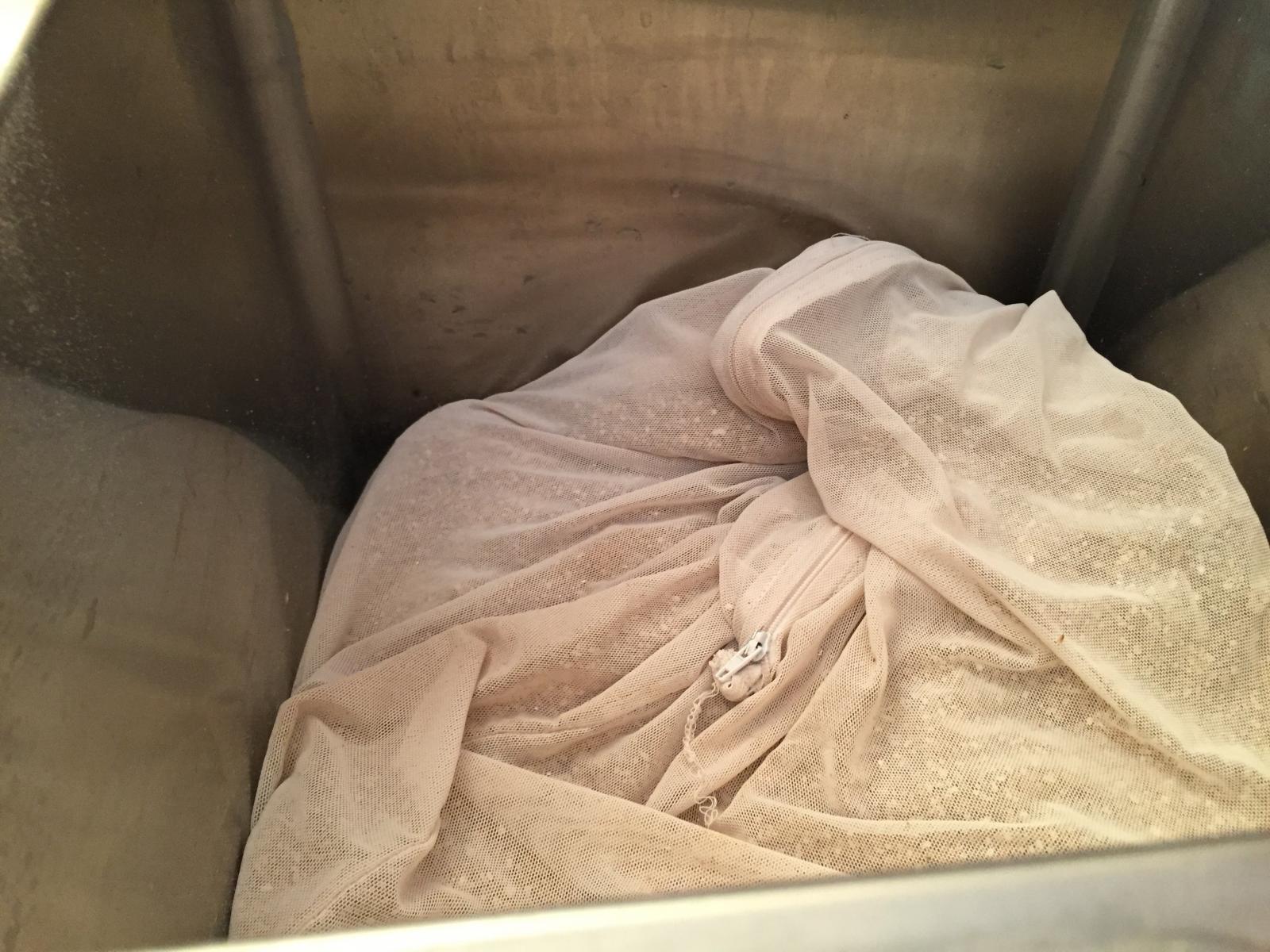

Next he dropped in the Malt, in a tight meshed bag.

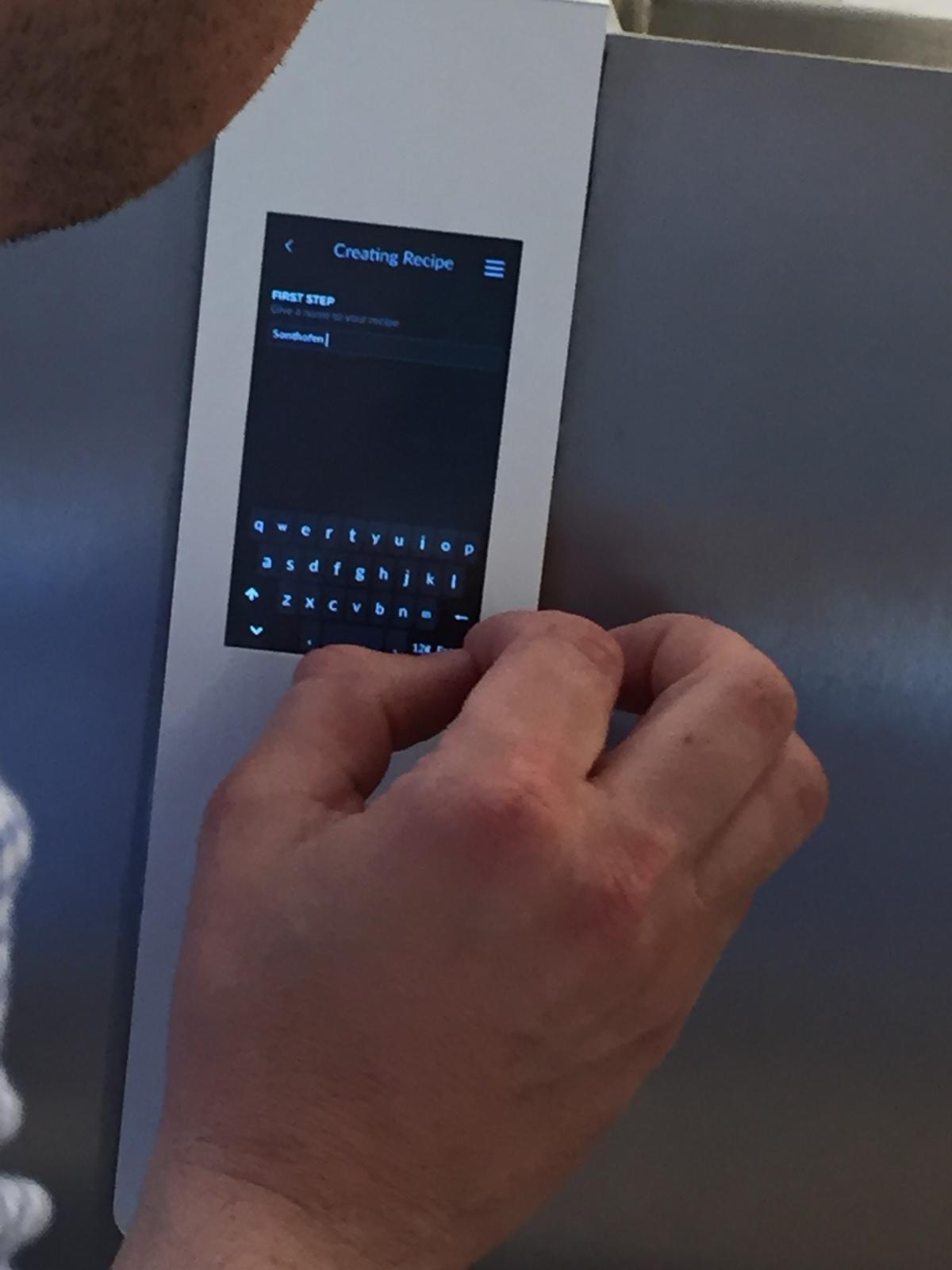

The machine was hooked up the water faucet and turned on. He then proceeded to manually enter the recipe, which was a bit of a pain, but said that this would usually be done through the smartphone or their website (to load / design recipes). The screen was very crisp, not at all sluggish, and the UI design, even though nowhere near finished according to our host, looked great!

The machine then began filling the left compartment, which has a heating device installed in the bottom. The water was heated, then pumped into the other compartment where the water was then constantly "pushed/ciruclated" through the Bag until mashing was complete. The water is routed through underneath the left compartment somehow at the stage, where it also is heated to keep the desired mash temperature.

After mashing is complete, new heated fresh water (from the left tank) is also added to the right tank to help wash out all the goodness from the grains. Eventually everything ends up in the left tank, where the boiling begins. Hop additions are automatic depending on how you program them. They work by circulating hot wort through the individual hop containers. There are tiny servo motors underneath each compartment that regulate the flow rate through each compartment, so as to create a "pulsing" - don't know exactly why this is good, but I reckon for better extraction.

The cooling down then happens with a plate chiller which is hooked up the fresh water supply, and then the wort is dumped into whatever fermentation vessel you have.

We then ran a quick cleaning cycle, where the water was heated and circulated, pumps ran forwards and backwards, and then the water was drained. It is in actual fact drained to the extent where there is zero water in any parts of the machine, be it tubing or anyything else. I have no idea how that works though. This has been a very recent (as in 1 week old) development in the design.

Concerning the effectiveness of the cleaning cycle we witnessed, he told us we are runnign the very basic of all the cleaning cycles, and these are still being tested with various chemicals or cleaning aids to see which cycles really do remove all of the beer remnants.

I've attached some photos to this post, hope they're not too large. I will add some videos soon too. Enjoy!

EDIT: can't figure out how to upload videos here, keeps saying "invalid file"