DubbelDach

Well-Known Member

OK, so I wanted to do a thread that was a tutorial on all-grain. It's intent is to be a good guide for new AGers, but also for people to spot holes in my game and suggest ways for me to be better. This is only about my 5th AG batch, so feel free to suggest better ways to do things. The entire gallery of pics can be seen here.

First off, the recipe:

Nut Brown Ale

(based off Lil' Sparky's recipe at the above link)

First lesson is read the recipe correctly. I only used 8 lbs of pale instead of 9. Duh. Only other change is that I used Safale-04 instead of the hard-to-find Nottingham.

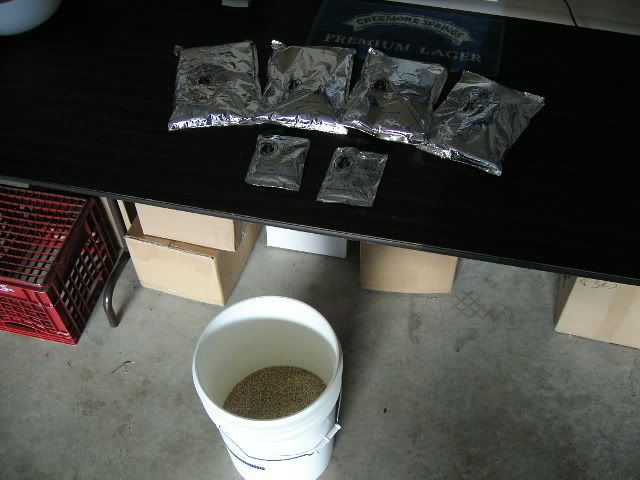

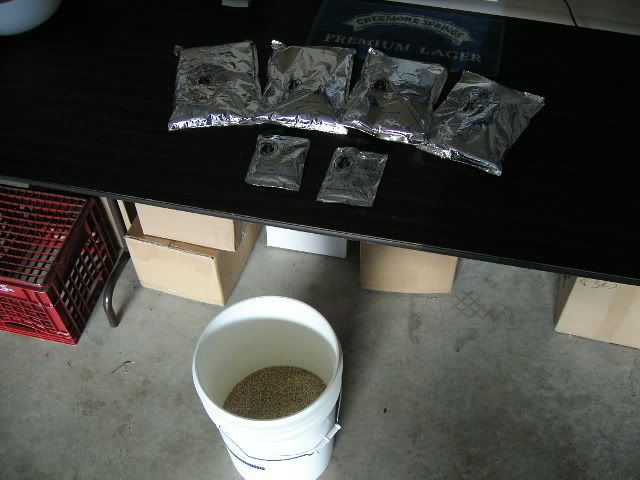

8 lbs. American 2-row info

1 lbs. Crystal Malt 60°L

8 oz. American Victory

4 oz. American Chocolate Malt

1 lbs. Oats Flaked

1 oz. Fuggle (Pellets, 4.75 %AA) boiled 60 min.

1 oz. East Kent Goldings (Pellets, 5.00 %AA) boiled 15 min.

DCL Yeast Safale S-04 Top Quality Ale Yeast

I always use this Mash Calculator for my strike and sparge water. Now, call me crazy, but it always gives a larger volume of water for the sparge, not the strike, so I always reverse them. Makes sense to me to add the larger volume first, where grain absorbtion is higher. Anyway, I heated my strike water and added it to the mash tun first:

Then I doughed in, stirring and breaking up dough balls as I poured the grain in:

First off, the recipe:

Nut Brown Ale

(based off Lil' Sparky's recipe at the above link)

First lesson is read the recipe correctly. I only used 8 lbs of pale instead of 9. Duh. Only other change is that I used Safale-04 instead of the hard-to-find Nottingham.

8 lbs. American 2-row info

1 lbs. Crystal Malt 60°L

8 oz. American Victory

4 oz. American Chocolate Malt

1 lbs. Oats Flaked

1 oz. Fuggle (Pellets, 4.75 %AA) boiled 60 min.

1 oz. East Kent Goldings (Pellets, 5.00 %AA) boiled 15 min.

DCL Yeast Safale S-04 Top Quality Ale Yeast

I always use this Mash Calculator for my strike and sparge water. Now, call me crazy, but it always gives a larger volume of water for the sparge, not the strike, so I always reverse them. Makes sense to me to add the larger volume first, where grain absorbtion is higher. Anyway, I heated my strike water and added it to the mash tun first:

Then I doughed in, stirring and breaking up dough balls as I poured the grain in:

\

\