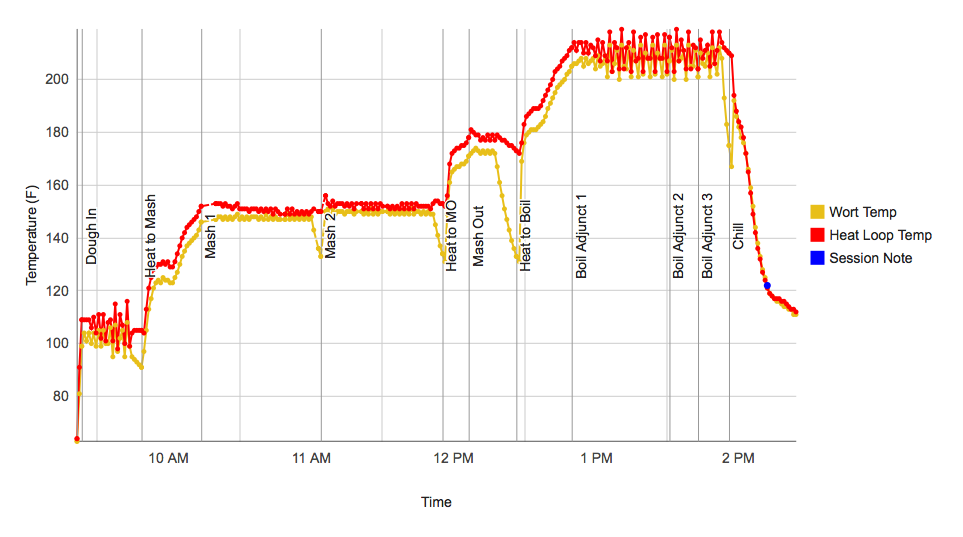

One other question I'm curious about: did you ferment in the keg as the picobrew videos show?

I've always used Better Bottles. I realize the batches here are small -- around 2.5 gallons (which is actually great for me because it's an excuse to always brew more) -- but I was wondering if it would make sense to transfer to a carboy or BetterBottle to ferment. I realize this negates the ability to force the beer from the keg for fermenter to the keg for server via CO2 -- but I'm wondering if there are any issues fermenting in the keg.

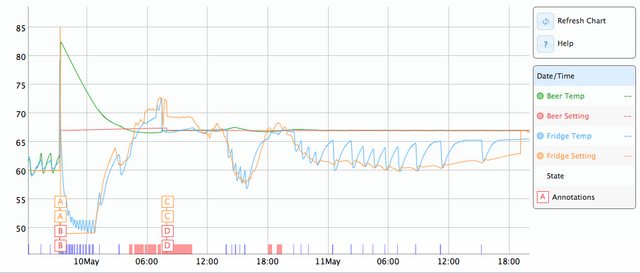

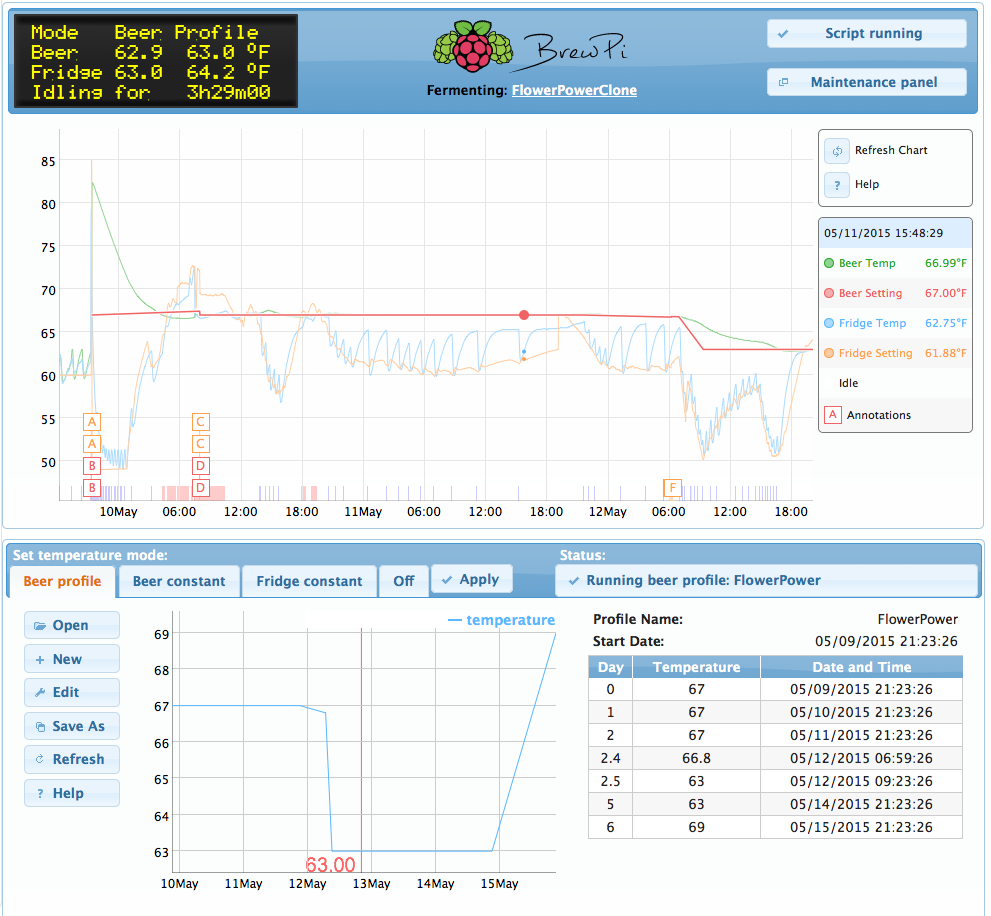

My basement is a steady 65F -- and I plan to use Safale-04 for the first few batches -- but I'm leery about not being to actually *see* the beer fermenting. It's common, obviously -- big stainless tanks and all -- but I'm wondering if it would make any sense at all to transfer.

Did you run into any fermentation issues? Or was the in-keg fermentation fine?

I've always used Better Bottles. I realize the batches here are small -- around 2.5 gallons (which is actually great for me because it's an excuse to always brew more) -- but I was wondering if it would make sense to transfer to a carboy or BetterBottle to ferment. I realize this negates the ability to force the beer from the keg for fermenter to the keg for server via CO2 -- but I'm wondering if there are any issues fermenting in the keg.

My basement is a steady 65F -- and I plan to use Safale-04 for the first few batches -- but I'm leery about not being to actually *see* the beer fermenting. It's common, obviously -- big stainless tanks and all -- but I'm wondering if it would make any sense at all to transfer.

Did you run into any fermentation issues? Or was the in-keg fermentation fine?