you are correct. I should have been specific. I close the temperature loop on the HLT temp, under the assumption that the MLT will follow it. I may add a deg or 2, to make up for my little coil.

With a 10' coil, and a big temp difference between the MLT and HLT, I'm not sure that you will get the effluence temp equal to the HLT temp. Doesn't matter though...

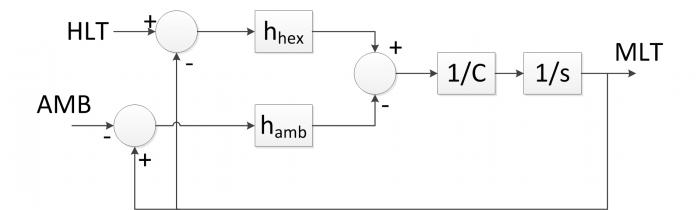

If you really want to use your idea, you would have to close the control loop with the MLT temperature, as with a significant difference in temps it is unlikely that you will be able to correctly guess at the temperature delta that will work. That is an inherently tricky concept though.

As an FYI, I have a doctorate in mechanical engineering, specifically in controls. If I seem long winded, pedantic, and overly confident of my own correctness, its because I am

The physical link between the HLT and MLT is only as strong as the heat exchange between them. If you have weak heat exchange (low flow and a short coil), it takes a long time to transfer energy to the MLT from the HLT.

Now there is a PID controller that is taking the MLT temperature tracking error in, and calculating the voltage output to the heating element in the HLT. When the MLT is slow to respond to the controller output, the controller will put out EVEN MORE to the heating element.

Pretty quickly, the heating element will get railed at full power. And at some point, the MLT temp will rise and get to the set point. Once this happens, you will probably have a very hot, if not boiling, HLT. You can't really actively cool the HLT (only heat. we have a one-sided control action), so it will probably cause the MLT to get much warmer than you intended. Eventually (hours?) you will get to a nice steady-state condition, and everything will be great. Before that happens, you will have taken your mash and HLT through big temperature sweeps.

The control solution, at least with a PID, is to decrease the I significantly, and maybe even back off on the P (you can't expect more control performance than is physically possible, after all). This means that your response will be very slow, and probably have significant steady-state error.

Luckily there is a solution

Since you already have 2 pumps, you can close 2 control loops. One is the HLT. Set it at something pretty high. Maybe 180-190 or so, but that is a guess. So, the HLT maintains its own temps by controlling the heating element while constantly recirculating (the faster the better). Close another loop around the MLT temp. This time, I'd use a hysteresis control law (unless you really want to mess with variable speed pumping) to turn the pump on/off. When the MLT temp drops below a certain point, the pump turns on. When the temp rises above a different point, the pump turns off. This should give, more or less, a set temperature range that the MLT will stay within. I'd shoot for maybe a 2-3 deg dead-band between the two set temps. Enough that the pump isn't cycling every few seconds, but not so much that you can't control the enzymatic reaction.

Wooboy, that was a long one.