The Pol

Well-Known Member

- Joined

- Feb 12, 2007

- Messages

- 11,390

- Reaction score

- 117

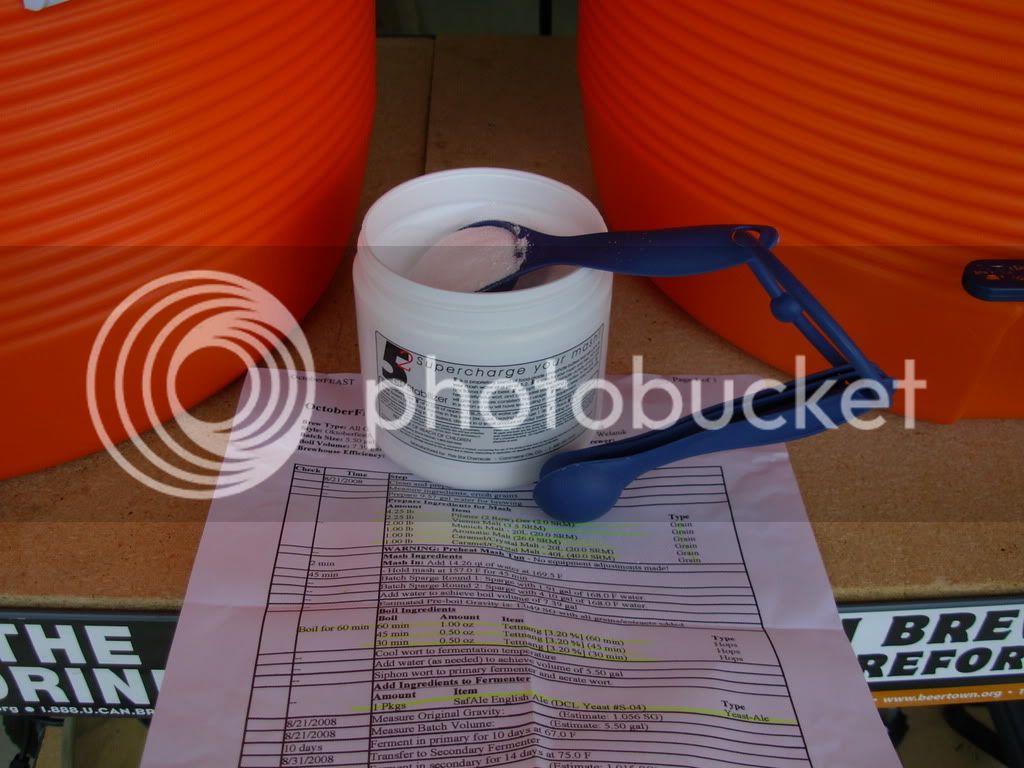

Fired up my new HERMS today... AWESOME!!! Heated the strike water to 177F while I was heading to the LHBS. When I got home I transferred 3.7 gallons to the MLT and mashed in. Tossed a frozen bottle of water into my HLT to get my HERMS water from 177F to 162F so that I could start the recirc.

I will be posting pics in a short while. Needless to say, it is working perfectly. I have the A419 on my HLT set at 162F with a 1F differential and my mash is recirculating at a comfy range from 157-158F. I have NEVER seen such clear wort in my life! It is a beautiful, crystal copper color (Octoberfest!).

Thanks to all who have built a HERMS and posted information here, thanks to Biermuncher for the inspiration on my OctoberFEAST brew. I will get pics up shortly, I am really just loving that I can sit here and clarify my wort, set up a nice filter bed and maintain my temp within about .5F and not have to lift a finger! (Looks and sounds cool too)

I will be posting pics in a short while. Needless to say, it is working perfectly. I have the A419 on my HLT set at 162F with a 1F differential and my mash is recirculating at a comfy range from 157-158F. I have NEVER seen such clear wort in my life! It is a beautiful, crystal copper color (Octoberfest!).

Thanks to all who have built a HERMS and posted information here, thanks to Biermuncher for the inspiration on my OctoberFEAST brew. I will get pics up shortly, I am really just loving that I can sit here and clarify my wort, set up a nice filter bed and maintain my temp within about .5F and not have to lift a finger! (Looks and sounds cool too)