splobucket

Well-Known Member

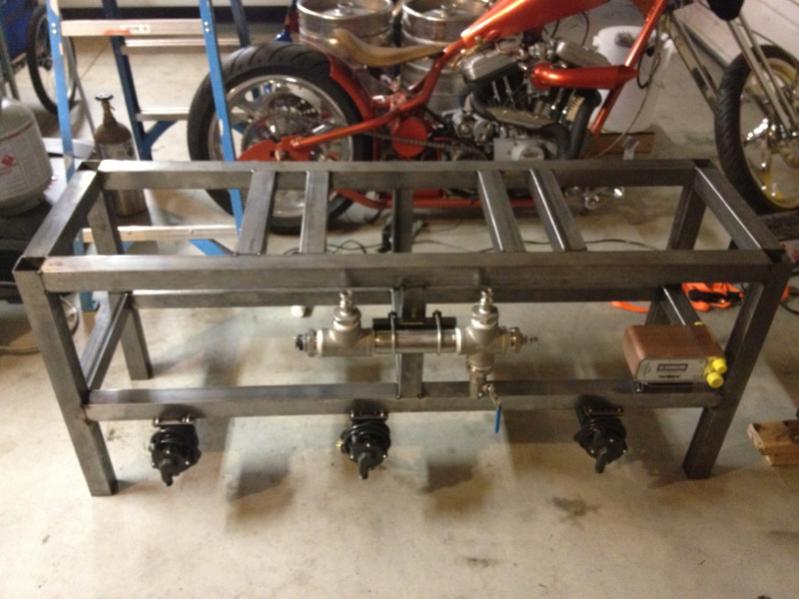

Doing a little bit of research on brew stands. I'm looking to design one, and I can't figure out why I would go with square vs. angle iron. Yes square is stronger, but stronger in a way like "i could run square over with my truck, but not angle" (which you probably could too). I figured angle would be easier to bolt to as well.

Also, aside from shiny-ness and non-rusting. Why stainless? Seems to me it would be prohibitively more expensive.

Comments? Insight?

Also, aside from shiny-ness and non-rusting. Why stainless? Seems to me it would be prohibitively more expensive.

Comments? Insight?