The biggest hurdle are the rollers. I propose the following. The rollers will be cast from cement!!! A 10 inch by 3 inch diameter pvc pipe will be fitted with a 3 inch to .5 inch reducer an each end (see pic below) and and have a .5 inch threaded rod centered in the two fittings. Once the form is assembled with the rod in place it will be filled with cement and left to cure. Once cured the pvc mold is cut away leaving a perfectly round roller.

What do you guys think???

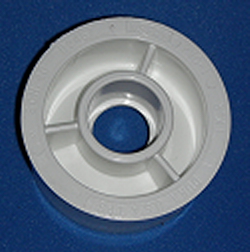

Here is a pic of the reducer from flexpvc.com

What do you guys think???

Here is a pic of the reducer from flexpvc.com