You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Control Products Dual Relay $60 Shipped on Amazon

- Thread starter NYC

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

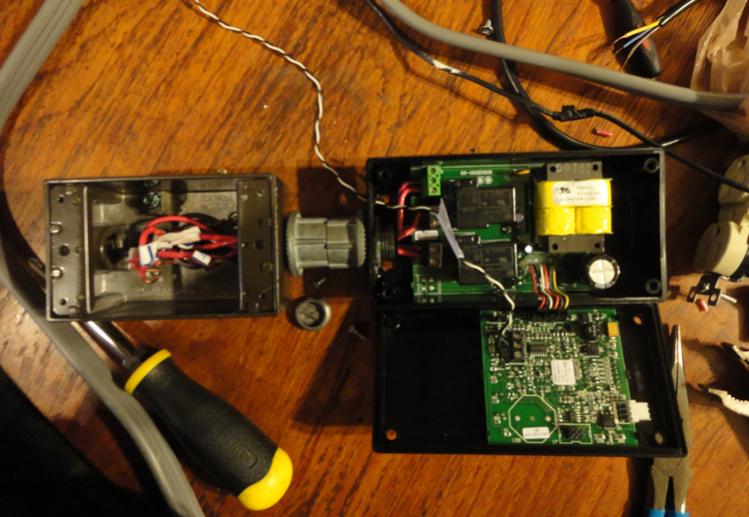

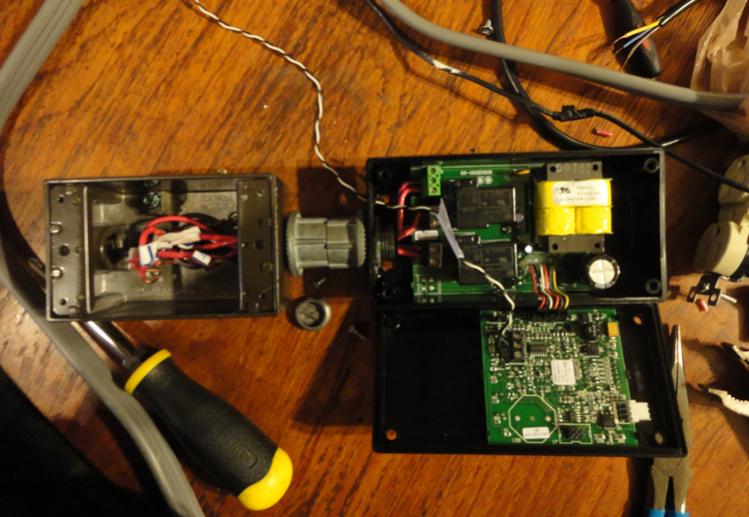

An update, after a few stops and starts (note to self: 20 AMP extension cord is very different than 15 AMP cord; 12 AWG wire is not easy to bend, etc.) I got it running today. I'm so excited, this was my first real electronic project.

Lincoln et. all, thanks so much! Your patience with someone as new to this type of project as I am is greatly appreciated.

Now to play around with it...

Lincoln et. all, thanks so much! Your patience with someone as new to this type of project as I am is greatly appreciated.

Now to play around with it...

LandoLincoln

Well-Known Member

Thanks to NYC for bringing this deal to our attention in the first place. Cheers!

Wiring up this bad boy thanks to everyone's help, but I have a few questions.

1. Has anyone extended the sensor lead? Did you just use 26 AWG wire? Where'd you get a short length?

2. Is it ok to just use a 14 AWG appliance cord (flat) to provide power? Seems like everyone was using generic round black extension cords

Thanks for your help guys!

1. Has anyone extended the sensor lead? Did you just use 26 AWG wire? Where'd you get a short length?

2. Is it ok to just use a 14 AWG appliance cord (flat) to provide power? Seems like everyone was using generic round black extension cords

Thanks for your help guys!

Imbibecules

Member

Thanks for all the info guys!

I had an old Johnson mechanical unit that bit the dust recently and this controller is the ideal replacement. I got it working over last weekend with Lando's modified wiring diagram, and drac0's part list from this thread https://www.homebrewtalk.com/f51/chest-freezer-fermentation-chamber-268999/index4.html.

There was some question as to extending the sensor lead. The PTC sensor that it ships with can be extended to 100' according to the manufacturer's web site. http://www.controlproductsonline.com/temperature-sensor-302degf-p-62-l-en.html I used a good pair of 24 AGW wires out of an otherwise damaged piece of CAT5 network cable to do so.

Also, make sure to read the manual and check the sensor for accuracy. I had to adjust the calibration on mine by 2 degrees.

Cheers!

I had an old Johnson mechanical unit that bit the dust recently and this controller is the ideal replacement. I got it working over last weekend with Lando's modified wiring diagram, and drac0's part list from this thread https://www.homebrewtalk.com/f51/chest-freezer-fermentation-chamber-268999/index4.html.

There was some question as to extending the sensor lead. The PTC sensor that it ships with can be extended to 100' according to the manufacturer's web site. http://www.controlproductsonline.com/temperature-sensor-302degf-p-62-l-en.html I used a good pair of 24 AGW wires out of an otherwise damaged piece of CAT5 network cable to do so.

Also, make sure to read the manual and check the sensor for accuracy. I had to adjust the calibration on mine by 2 degrees.

Cheers!

I'm considering getting one of these but I'm a total noob at dealing with electrical wiring. I was looking at the manufacturer's website and was wondering why you guys didn't mimic their diagram. http://www.protectedhome.com/documents/TC9102DHV 120 VAC Wiring Diagram.pdf

Any other help is appreciated. I'd like to get this one, but I keep wavering because I'm not confident with electricity. It kills!

Any other help is appreciated. I'd like to get this one, but I keep wavering because I'm not confident with electricity. It kills!

LandoLincoln

Well-Known Member

I'm considering getting one of these but I'm a total noob at dealing with electrical wiring. I was looking at the manufacturer's website and was wondering why you guys didn't mimic their diagram. http://www.protectedhome.com/documents/TC9102DHV 120 VAC Wiring Diagram.pdf

Any other help is appreciated. I'd like to get this one, but I keep wavering because I'm not confident with electricity. It kills!

Their wiring diagram wasn't that helpful to me, and using their diagram I didn't wire it right. Maybe the problem is mine, I don't know. But the way I wired it is the same way that the other guys that use the ebay aquarium temp controller wire theirs, and mine has been working just fine for the past few months.

Don't be afraid of this electrical project. It's not that complicated once you get into it.

- Joined

- Oct 30, 2011

- Messages

- 41

- Reaction score

- 7

I've wired one of these up and want to configure it to keep a fridge at a set temp.

I've successfully turned off relay2 which I won't be using, but I could really use some help figuring out how Set Point1, High Set Point1, Low Set Point1 work.

I can set the values but I don't understand how they work together.

Could someone post an example to help get me started?

Thanks!

I've successfully turned off relay2 which I won't be using, but I could really use some help figuring out how Set Point1, High Set Point1, Low Set Point1 work.

I can set the values but I don't understand how they work together.

Could someone post an example to help get me started?

To keep the fridge at 45 degrees:

SP1 = ___

HSP1 = ___

LSP1 = ___

SP1 = ___

HSP1 = ___

LSP1 = ___

Thanks!

LandoLincoln

Well-Known Member

I've wired one of these up and want to configure it to keep a fridge at a set temp.

I've successfully turned off relay2 which I won't be using, but I could really use some help figuring out how Set Point1, High Set Point1, Low Set Point1 work.

I can set the values but I don't understand how they work together.

Could someone post an example to help get me started?

To keep the fridge at 45 degrees:

SP1 = ___

HSP1 = ___

LSP1 = ___

Thanks!

The HSL (high side limit) and LSL (low side limit) don't do anything to the temperature. The HSL and LSL function is there to constrain your choices to a certain range. This is useful if some doofus comes along and tries to set the unit too high or too low. But since you're probably going to be the only doofus using this unit, it's okay to bypass this safety feature.

I set my HSL to 90° (which is higher than I'll ever go) and my LSL to 30° (which is lower than I'll ever go).

SP1 would be set to the "COOL" function.

Let's assume your stage 1 differential (df1) is set to 3° (which is the default), then the unit will turn on SP1 when the temp reaches 3° above whatever you set, and then will cool it down to the set point.

So if you want temps to stay in the 42° to 45° range, set the SP1 to 42°.

If that is too wide of a temperature range, you're going to have to lessen the differential to something less than 3. Doing this is going to kick your compressor on more frequently, though, and that will shorten the life of the compressor.

To the OP, I checked one of these out, the wiring isn't too hard, but the incremental cost between this and a wired Johnson control is, like, $25. I think for the cost of the cord ($8-$12) and the aggravation, I'd just buy that. If you got it on Amazon returns are pretty easy.

louie0202

Well-Known Member

Quick question, I miswired this and threw a breaker.....now whenever I use it...even though Stage 1 shows off, it is powered and Stage 2 is regulated properly.

I wired it per this post after I threw the breaker....is it possible to burn out the Stage and cause it to be always on or is this most likely a wiring issue?

Thanks,

Pat

I wired it per this post after I threw the breaker....is it possible to burn out the Stage and cause it to be always on or is this most likely a wiring issue?

Thanks,

Pat

I'm not an electrician but I don't think it's possible to "burn out" a relay and cause it to be on all the time. If anything, it would never turn on. I would guess it is a wiring issue.

I just wired mine up and after looking at the diagram on the website. the relay switches the ground, not the hot wire. If you are wiring from an AC power cord, the white one is patched into the relay and the black is put directly to the outlet (that the fridge or heater is plugged into).

All in all, pretty easy to wire this - certainly no more difficult than the ranco unit. I did the same thing as an earlier poster with an outlet that I broke the bridge clip on. I have a tiny space heater (that sits inside the chest freezer) plugged into the top outlet and the chest freezer plugged into the bottom outlet.

I just wired mine up and after looking at the diagram on the website. the relay switches the ground, not the hot wire. If you are wiring from an AC power cord, the white one is patched into the relay and the black is put directly to the outlet (that the fridge or heater is plugged into).

All in all, pretty easy to wire this - certainly no more difficult than the ranco unit. I did the same thing as an earlier poster with an outlet that I broke the bridge clip on. I have a tiny space heater (that sits inside the chest freezer) plugged into the top outlet and the chest freezer plugged into the bottom outlet.

That is wrong, and totally unsafe.

You never want to leave the 'hot' wire on all the time. The hot wire should be switched by the relay.

If you wired yours with the hot on all the time you should rewire it correctly.

B

You never want to leave the 'hot' wire on all the time. The hot wire should be switched by the relay.

If you wired yours with the hot on all the time you should rewire it correctly.

B

adamreef

Well-Known Member

bad coffee said:That is wrong, and totally unsafe.

You never want to leave the 'hot' wire on all the time. The hot wire should be switched by the relay.

If you wired yours with the hot on all the time you should rewire it correctly.

B

I'm not generally one to post just to add a +1, but it is warranted here. This is very dangerous for a variety of reasons, not the least of which is that if someone sees the light off in the fridge (or it won't kick on), they may assume that no power is being delivered to the device or the receptacle when it will in fact be live all the time.

I have both been shocked and had a small fire because a previous homeowner wired circuits this way.

Adam

musicis

Active Member

Just bought two of these for two 14.8 cf freezers for my garage here in the Chicago area. I work with electrical all the time in my decorating business so i have outlets, boxes, 14 & 12 solid wire, caps and all lying around so this looks like a no brainer to me. Most important is everyone seems quite happy with the results after its assembled.

Whats the best option for the heating element? I assume 14 gauge wire is good for the heater if its only a 4 foot run. Just drop it in the back hinge side between the weather strip like the thermometer?

Whats the best option for the heating element? I assume 14 gauge wire is good for the heater if its only a 4 foot run. Just drop it in the back hinge side between the weather strip like the thermometer?

LandoLincoln

Well-Known Member

Just bought two of these for two 14.8 cf freezers for my garage here in the Chicago area. I work with electrical all the time in my decorating business so i have outlets, boxes, 14 & 12 solid wire, caps and all lying around so this looks like a no brainer to me. Most important is everyone seems quite happy with the results after its assembled.

Whats the best option for the heating element? I assume 14 gauge wire is good for the heater if its only a 4 foot run. Just drop it in the back hinge side between the weather strip like the thermometer?

I believe 14 gauge wire is rated for 15 amps, so yeah, any little heater isn't going to draw more than 4 or 5 amps. But check the unit in question to be sure.

Take a look at the STC-1000 build threads. They are actually very easy to assemble and operate. I built one into a 2 outlet old work blue plastic box and it works great for running the fridge and heat wraps. They are actually very easy to build and get working properly. I can keep my lager temps at around 45 degrees in the Fla summer heat pretty easilly. I am using a dorm frige made into a blue board chamber and the larger volume makes it a little slower cooling, but once it gets there it maintains it extremely well. My total investment was less than 20 bucks for everything including the STC-1000, circuit box, outlet and cover. I already had a cord and wiring here, so I didnt have to buy any more stuff to get it to work great. Hope this helps to get you back on the path and going again.

Wheelchair Bob

Wheelchair Bob

LandoLincoln

Well-Known Member

Take a look at the STC-1000 build threads. They are actually very easy to assemble and operate. I built one into a 2 outlet old work blue plastic box and it works great for running the fridge and heat wraps. They are actually very easy to build and get working properly. I can keep my lager temps at around 45 degrees in the Fla summer heat pretty easilly. I am using a dorm frige made into a blue board chamber and the larger volume makes it a little slower cooling, but once it gets there it maintains it extremely well. My total investment was less than 20 bucks for everything including the STC-1000, circuit box, outlet and cover. I already had a cord and wiring here, so I didnt have to buy any more stuff to get it to work great. Hope this helps to get you back on the path and going again.

Wheelchair Bob

I've built both, and the STC-1000 is okay, and it can fit in a tighter enclosure, but this one is in °F, and has a few other features that the STC-1000 does not have.

PacificNWBrewer

Well-Known Member

I love this thread! I want to build a keezer/fermentation chamber (basically this http://www.wortomatic.com/articles/The-Mother-of-All-Fermentation-Chillers) and need a controller to run the keezer at serving temp and one to control the fermentation chamber. I was thinking of using the TC-9102D-HV Dual Stage to run the chamber and a STC-1000 to run the keezer. However, if you're Amazon Prime, the TC-9102D is $59 rather than $120. At that price, I could get 2 and run all of it with both. http://www.amazon.com/dp/B0057APR3I/?tag=skimlinks_replacement-20

Any other suggestions or advice?

Thank you!

Any other suggestions or advice?

Thank you!

Last edited by a moderator:

BungBrewing

Well-Known Member

I love this thread! I want to build a keezer/fermentation chamber (basically this http://www.wortomatic.com/articles/The-Mother-of-All-Fermentation-Chillers) and need a controller to run the keezer at serving temp and one to control the fermentation chamber. I was thinking of using the TC-9102D-HV Dual Stage to run the chamber and a STC-1000 to run the keezer. However, if you're Amazon Prime, the TC-9102D is $59 rather than $120. At that price, I could get 2 and run all of it with both. http://www.amazon.com/dp/B0057APR3I/?tag=skimlinks_replacement-20

Any other suggestions or advice?

Thank you!

You're not going to be able to control two temperature zones with this controller. You can use it to control two-stage heating (to control minimum temperature), two-stage cooling (to control maximum temperature), or control both heating and cooling (to control maximum and minimum temperatures). It only has one sensor for a single zone. Dual zone controllers are available (I believe Love make them), but they can be expensive...

Last edited by a moderator:

PacificNWBrewer

Well-Known Member

Thank you for the feedback but I know one controller will not do what I need. I stated I wanted to use one type for the top chamber and another for the bottom. Should have been more clear about that, sorry.

Finally took the time to register here after getting my fermentation chamber up and running.

I owe a HUGE thanks to the posters in this thread, in particular LandoLincoln.

I came into this project with absolutely no electricial knowledge, very little patience and large, clumsy hands. The images and descriptions in this thread saved me a good $50 and have me a solid DIY buzz.

I owe a HUGE thanks to the posters in this thread, in particular LandoLincoln.

I came into this project with absolutely no electricial knowledge, very little patience and large, clumsy hands. The images and descriptions in this thread saved me a good $50 and have me a solid DIY buzz.

LandoLincoln

Well-Known Member

Finally took the time to register here after getting my fermentation chamber up and running.

I owe a HUGE thanks to the posters in this thread, in particular LandoLincoln.

I came into this project with absolutely no electricial knowledge, very little patience and large, clumsy hands. The images and descriptions in this thread saved me a good $50 and have me a solid DIY buzz.

Glad we could help! Lord help you if you've got the brewing DIY bug now. Stay away from the keezer threads! They'll suck you right in!

A second Cheers to LandoLincoln! Just got mine wired and tested. Thanks for the diagram and the tip on the junction box (I was just going to make a squid originally). Will be setting it up on the lager fridge soon (waiting on my BeerBug to arrive to brew the first batch to go in).

IMNOTL8

Member

I just got around to wiring the TC-9102 this past weekend for my kegerator/lagering refrigerator. Everything seems to be working right but was curious how you guys have your temperature probe mounted/placed? I just have the PTC sensor that came with the unit. I know this is not supposed to be submerged in fluid, but has anyone built something that just the tip sits in some sort of fluid for a more accurate temp? Any pictures of your placement would be awesome!

LandoLincoln

Well-Known Member

I just got around to wiring the TC-9102 this past weekend for my kegerator/lagering refrigerator. Everything seems to be working right but was curious how you guys have your temperature probe mounted/placed? I just have the PTC sensor that came with the unit. I know this is not supposed to be submerged in fluid, but has anyone built something that just the tip sits in some sort of fluid for a more accurate temp? Any pictures of your placement would be awesome!

I usually use Brewhaulers on my carboys, and I take the probe and place it between one of the Brewhauler straps and the glass of the carboy. Is that the BEST way to do it? I don't know. But it seems to work well.

Smuve21

Member

Question, I've bought one of these controllers and I was wiring it up here and there when I had some time to sit down. Where is the number 9 wire coming from? Is this coming off of the power plug?

Question, I've bought one of these controllers and I was wiring it up here and there when I had some time to sit down. Where is the number 9 wire coming from? Is this coming off of the power plug?

I used this thread as a reference when I built my controller. Yes, wire 9 comes from the power plug. It is wired together with the white wire in the power cord and the white wire that goes to the controller.

Tomcat0304

Well-Known Member

So, Is this the correct wiring diagram? I have not tried wiring anything previously. Based on this diagram it looks like there would be 4 places where 3 wires come together in wire nuts, correct? Or, would it be better (possible?) to have the hot wire from the incoming power, one wire from stage 1, and one wire from stage 2 all in the 120 screw? Again, I've never messed with electricity before, so, please forgive my ignorance.

View attachment TC-9102 HV Wiring Diagram.pdf

View attachment TC-9102 HV Wiring Diagram.pdf

Looking at the drawing, for a dual-stage setup the hot (black) feed circuit would require four wires inside a nut, as would the neutral (gray) circuit. The safety ground only needs three, and then there are the two jumpers for the stage outputs to the loads that are "nutless" (yeah, I said it  ) That's how I wired all of my dual-stage controllers, as I can over-size the wiring with only single ends inside the terminals...

) That's how I wired all of my dual-stage controllers, as I can over-size the wiring with only single ends inside the terminals...

Cheers!

Cheers!

Tomcat0304

Well-Known Member

Is there anything wrong with keeping all the pigtails, wire nuts, and connections within the outlet box and having a 4'-5' run between the controller and outlet box?

LandoLincoln

Well-Known Member

Is there anything wrong with keeping all the pigtails, wire nuts, and connections within the outlet box and having a 4'-5' run between the controller and outlet box?

Nope.

Tomcat0304 said:Is there anything wrong with keeping all the pigtails, wire nuts, and connections within the outlet box and having a 4'-5' run between the controller and outlet box?

That's how mine's setup. So it might still be wrong, but at least you're in good company!

Imbibecules

Member

I just wanted to add that you can get better temperature readings using a thermowell. It was sort of a pain to find one with an i.d. that would fit the probe for this controller, but my search paid off with this product. http://www.brewershardware.com/16-Stainless-Steel-Thermowell.html Also, I forget which month it was, but BYO magazine had a good article sometime in 2012 that was about temperature controllers, sensor placement, use of a thermowell, temperature fluctuations, and so on. The gist of it is that thermowells are great at giving you a more accurate temperature reading, and help smooth out the fluctuations in beer temperature inside of your freezer.

One caveat that they had pointed out, which should have been common sense (therefore it escaped me), is that your freezer will probably dip dangerously low in temperature right after you put a new beer in it if you set your controller to your final fermentation point and are using a thermowell. The reason is obvious. Basically, the center of the liquid stays warmer for a longer period of time than the edges of the liquid which may get cool enough to give you some yeast activity concerns, particularly on ales.

This makes me a bit paranoid, so now I use the tape the thermowell to the side of the vessel and cover it with an insulator and more tape for the initial cooling of the freezer/vessel. Once I get down to the set point I move the probe to the thermowell that has been in place the whole time.

Of course if I have multiple beers that are slightly staggered in fermentation, this isn't a problem, except for the first beer that goes in. Which is just another excuse to continually brew.

One caveat that they had pointed out, which should have been common sense (therefore it escaped me), is that your freezer will probably dip dangerously low in temperature right after you put a new beer in it if you set your controller to your final fermentation point and are using a thermowell. The reason is obvious. Basically, the center of the liquid stays warmer for a longer period of time than the edges of the liquid which may get cool enough to give you some yeast activity concerns, particularly on ales.

This makes me a bit paranoid, so now I use the tape the thermowell to the side of the vessel and cover it with an insulator and more tape for the initial cooling of the freezer/vessel. Once I get down to the set point I move the probe to the thermowell that has been in place the whole time.

Of course if I have multiple beers that are slightly staggered in fermentation, this isn't a problem, except for the first beer that goes in. Which is just another excuse to continually brew.

LandoLincoln

Well-Known Member

Of course if I have multiple beers that are slightly staggered in fermentation, this isn't a problem, except for the first beer that goes in. Which is just another excuse to continually brew.

If you have beers that are staggered in fermentation, then it's best to just read the ambient air temps around both batches to try to keep them both at the same temps, and know that the beer is going to get about 5 degrees warmer than ambient air temps. So if you'd like your beers to be fermenting at around 65°, then set the temp controller to keep the air at 60°. Your compressor will kick on more frequently, but more importantly, both batches of beer will be at the appropriate temps.

kevinb

Well-Known Member

- Joined

- Mar 19, 2012

- Messages

- 651

- Reaction score

- 36

I am just getting ready to wire one of these. I noticed in previous posts that the controller relays are rated to 20 Amps. The paperwork that I got with mine says only 8 amps if both relays are running at the same time or 16 Amps if they are not. Anyone know what the story is? It is not a big deal since the heater will not be running the same time as the freezer and neither draws 16 amps, just curious.

Similar threads

- Replies

- 33

- Views

- 8K

- Replies

- 0

- Views

- 3K

- Replies

- 6

- Views

- 1K

- Replies

- 2

- Views

- 2K