You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The cure for your short hose troubles

- Thread starter pjj2ba

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Hmm.. I don't like that they'll get brittle, makes me wonder if I'm drinking plastic.

But these are very brittle to start with (I broke a couple just fat fingering them while cleaning). Then with them being cold, they would be even more so brittle. Guess I am saying... are we sure that these are getting more brittle due to wear? or just from factors like the above?

They do work well. However, there definitely is some interaction between the beer and the plastic, as over months/years they become quite brittle.

Fortunately I have a friend in the metalworking industry who made me essentially the same thing, but made of 316 stainless. They work awesome and will last forever.

Unfortunately, it's not economically viable to manufacture and sell them. They'd have to retail for around $14.

Michael

These things would still be cheaper at $14 than the Insta balance at 15.99 before shipping. Plus your's is easier to clean since it's not mesh.

Give me a break. The mixer pieces are dirt cheap: "over months/years" - ???They do work well. However, there definitely is some interaction between the beer and the plastic, as over months/years they become quite brittle.

...l

How about replacing them after a keg batch or three?

Months???

Years???

How often do you replace your beer lines? Years?

BrewersKaramazov

Well-Known Member

This might help your "short hose troubles". MAXODERM

Glad to see someone went there.

My point was simply that there seems to be a chemical interaction between the beer and the plastic. I'd rather not have them in my beer if that's the case. I have no way of knowing how long, or at what levels they begin to degrade. Pure speculation on my part. Your experience may vary....

I am glad they're working out for you.

Carry on....

Michael

I am glad they're working out for you.

Carry on....

Michael

Give me a break. The mixer pieces are dirt cheap: "over months/years" - ???

How about replacing them after a keg batch or three?

Months???

Years???

How often do you replace your beer lines? Years?

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

Give me a break. The mixer pieces are dirt cheap: "over months/years" - ???

How about replacing them after a keg batch or three?

Months???

Years???

How often do you replace your beer lines? Years?

Haha - It may sound bad, and perhaps it is. But I have my beer lines in and have had never changed them (because it is a PITA for my set up). They have been in for over a year. I think I have given a total of 3 good and hot concentrated PBW soaks on the lines. I plan on taking everything aprt over thanksgiving. So I will see how bad they look! haha

I can't imagine that they are any worse than drinking bottled water... This is one of those things that falls into the line of... the beer is worse for your health than if you ate one mixer stick per keg of brew.

Now if I had the opportunity to replace the plastic mixers with all food grade stainless... I would do it if possible because in general I don't like plastic in contact with foods, etc unless there isn't another reasonable option.

camiller

Well-Known Member

...

Fortunately I have a friend in the metalworking industry who made me essentially the same thing, but made of 316 stainless. They work awesome and will last forever.

...

Michael

Seems like it would be easier/cheaper to simply put a flat flange on some 1/8" ID stainless tubing as a replacement for the dip tube instead of milling an epoxy mixer out of stainless.

Heck, it shouldn't be too hard just to figure out what diameter straight stainless rod you could drop down the dip tube to give the equivalent resistance.

I bet some enterprising person could take some thin 1/4" wide stainless steel strip, chuck it into a drill, put enough twists into it to produce essentially the same device, then market the heck out of it...

Cheers!

Cheers!

The ones I had made are not CNC milled, but extruded through a die I believe - using big, expensive machinery. They are quite rigid.

I am not sure how the "1/8" tubing with a flat flange" or a "1/4" strip chucked into a drill" would work exactly, but seems like there's a market if you can do it cheap enough.

Good luck!

Michael

I am not sure how the "1/8" tubing with a flat flange" or a "1/4" strip chucked into a drill" would work exactly, but seems like there's a market if you can do it cheap enough.

Good luck!

Michael

Seems like it would be easier/cheaper to simply put a flat flange on some 1/8" ID stainless tubing as a replacement for the dip tube instead of milling an epoxy mixer out of stainless.

Heck, it shouldn't be too hard just to figure out what diameter straight stainless rod you could drop down the dip tube to give the equivalent resistance.

camiller

Well-Known Member

...

I am not sure how the "1/8" tubing with a flat flange" ... would work exactly...

Michael

Basically what I am suggesting is to replace the 1/4" dip tube with a 1/8" dip tube. Since there is no such thing as a 1/8" dip tube you would have to fabricate one by taking 1/8" tubing and weld/solder a flat piece with a 1/8" hole in it to the top of the tube like the flange on a normal 1/4" dip tube. The narrower tubing would provide more resistance.

Sounds like an idea! Let us know how it turns out.

Michael

Michael

Basically what I am suggesting is to replace the 1/4" dip tube with a 1/8" dip tube. Since there is no such thing as a 1/8" dip tube you would have to fabricate one by taking 1/8" tubing and weld/solder a flat piece with a 1/8" hole in it to the top of the tube like the flange on a normal 1/4" dip tube. The narrower tubing would provide more resistance.

Why not just put the 1/8 tube inside the 1/4? I like to over complicate things. But what is the diameter of the 1/8"? Is that I.D. or O.D.?

CanadianQuaffer

Well-Known Member

They do work well. However, there definitely is some interaction between the beer and the plastic, as over months/years they become quite brittle.

Fortunately I have a friend in the metalworking industry who made me essentially the same thing, but made of 316 stainless. They work awesome and will last forever.

Unfortunately, it's not economically viable to manufacture and sell them. They'd have to retail for around $14.

Michael

Personally I think $14 per is a steal if it:

a) reduces foam

b) lasts forever

c) won't react with your beer at all and

d) you only need one per keg.

If your friend can make more, sign me up!

camiller

Well-Known Member

Why not just put the 1/8 tube inside the 1/4? I like to over complicate things. But what is the diameter of the 1/8"? Is that I.D. or O.D.?

1/8" ID, somewhere either earlier in this thread or somewhere else somebody suggested putting 1/8" ID plastic hose inside a dip tube, which seemed to work IIRC. Just putting 1/8 stainless, which would have thinner walls would not cause much restriction because beer would flow around the outside as well as the inside. If I did the math right a solid stainless rod about .1" or .11" insert in the tube would be about the same restriction....

((((.125 ** 2) * pi) - (((.125 / 2) ** 2) * pi)) / pi) ** .5 = 0.108253175

a 1/8" four foot long stainless rod is $3.36 at the first place I checked.

At any rate, my system works with 8' of beer line so I have no need for any of these solutions, I'll leave it for others to test

CidahMastah

Well-Known Member

- Joined

- Nov 12, 2010

- Messages

- 4,201

- Reaction score

- 46

1/8" ID, somewhere either earlier in this thread or somewhere else somebody suggested putting 1/8" ID plastic hose inside a dip tube, which seemed to work IIRC. Just putting 1/8 stainless, which would have thinner walls would not cause much restriction because beer would flow around the outside as well as the inside. If I did the math right a solid stainless rod about .1" or .11" insert in the tube would be about the same restriction....

((((.125 ** 2) * pi) - (((.125 / 2) ** 2) * pi)) / pi) ** .5 = 0.108253175

a 1/8" four foot long stainless rod is $3.36 at the first place I checked.

At any rate, my system works with 8' of beer line so I have no need for any of these solutions, I'll leave it for others to testIf I ever set up a portable system I may try this to see what happens.

The 1/8'' rod idea is interesting. Simply cut it to length to get the correct restriction. Where would you buy rod like this? I assume HD doesn't have it (or at least I haven't see it.)

Does the mixer sticks cause any turbulence? If the idea is to drop the pressure or cause restriction couldn't you add a series of crimps in the tube? I could see it being a problem putting in and taking out your dip tube.. Or better yet how about a rounded cutting bit on a pipe cutter to deform the ID smaller in series? I'm sure the tube would grow in length and become delicate from thinning the wall but I guess cleaning would be problematic with both scenarios just talking out my bunghole guys...lol..

just talking out my bunghole guys...lol..

just talking out my bunghole guys...lol..

just talking out my bunghole guys...lol..I've been using some of these mixing sticks for a while now. And although they definitley slow down the pour it seems to me that they may be knocking out the gas from the beer as it flows over the mixers. I just find the beer doesn't have much carbonation after I pour. Yes, I don't get a glass of all foam, but now I hardly get a head at all. Does anyone else see this happening?

I've been using some of these mixing sticks for a while now. And although they definitley slow down the pour it seems to me that they may be knocking out the gas from the beer as it flows over the mixers. I just find the beer doesn't have much carbonation after I pour. Yes, I don't get a glass of all foam, but now I hardly get a head at all. Does anyone else see this happening?

I've just started using them and haven't tried them with a fully carbed batch other than my Oatmeal stout which tends to have a low fast dissipating head due to the oils. It pours with very little head for me using 2 sticks -- which is probably slightly too much resistance -- but if I half open my picnic tap and give it a shot of foam it gets a decent head on it.

I've got a few batches that should be carbed up properly soon (I'm a set and forgetter) and then I'll report back. I'd expect if the CO2 was getting knocked out though, you'd see foam though since it'd happen on the way through the tube out... much like the restrictor plate in a stout faucet causes the co2 to knock out and foam.

I am new to kegging and was having foam problems with my very first kegged batch. After trying several solutions, I decided to try the swizzle stick method.

While reading all of the pages in this thread, I had a hard time picturing what the swizzle sticks were like, until someone posted a pic of one and that helped a lot. In my reading, I also saw that many people were having trouble picturing how to get the swizzle out of the shaft it comes in, so I took some pics at various points in the process of taking the swizzle out. Believe me, it's a very easy and fast process, but just to give people an idea of what they will be doing, I thought I would post the pics here as an "illustrated tutorial", or whatever. I hope it helps.

Just some background, my beer is a stout at about 38*F at 10psi. It's in a ball lock keg with about 5ft of tubing with a party tap at the end, typical of kegconnection.

Funnily enough, I have yet to insert the swizzles in my keg as I'm waiting for the beer to get back to being carbed. It had gotten over carbed so I released all the pressure, "flattened" it out and then recarbed it using the "set and forget" technique. Wish me luck when I actually put them in.

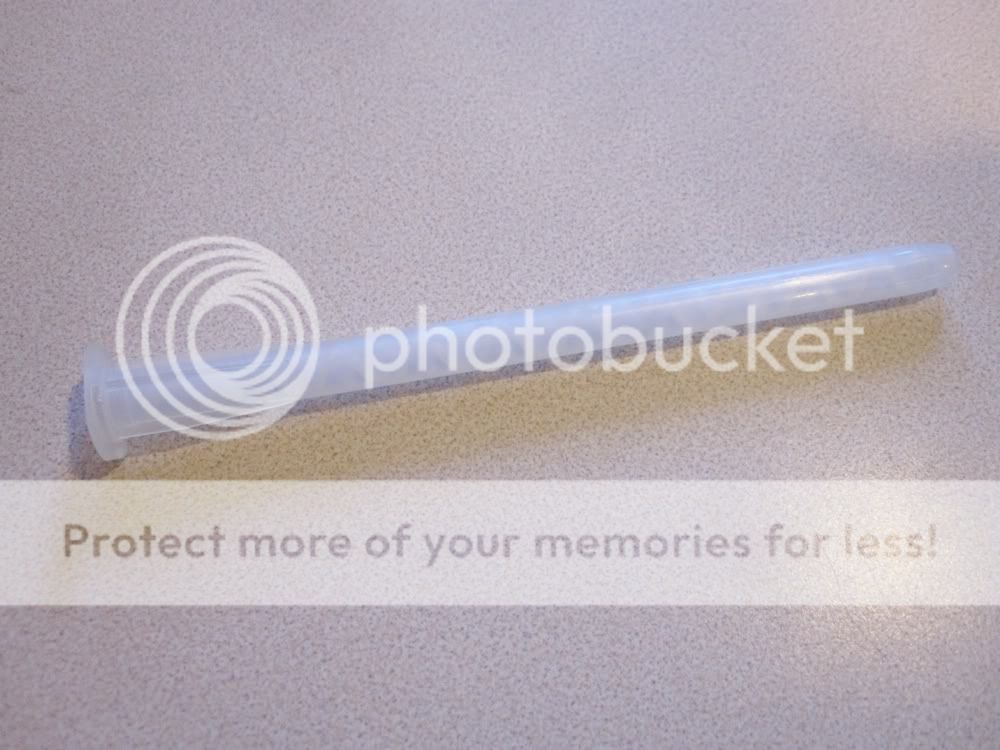

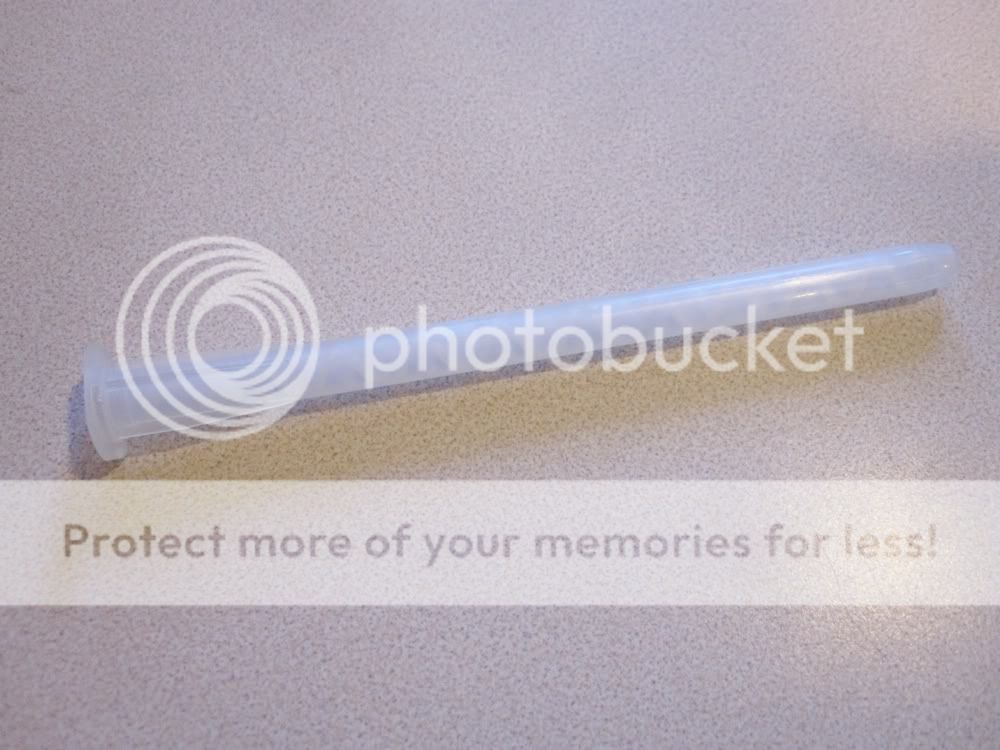

The tube with the swizzle still inside

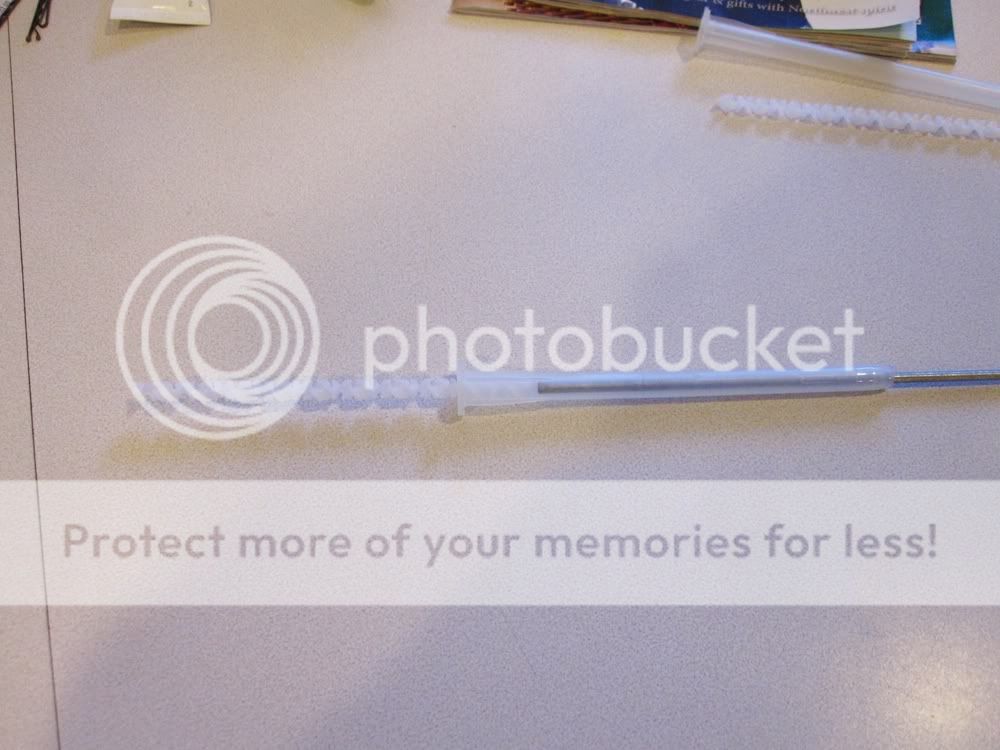

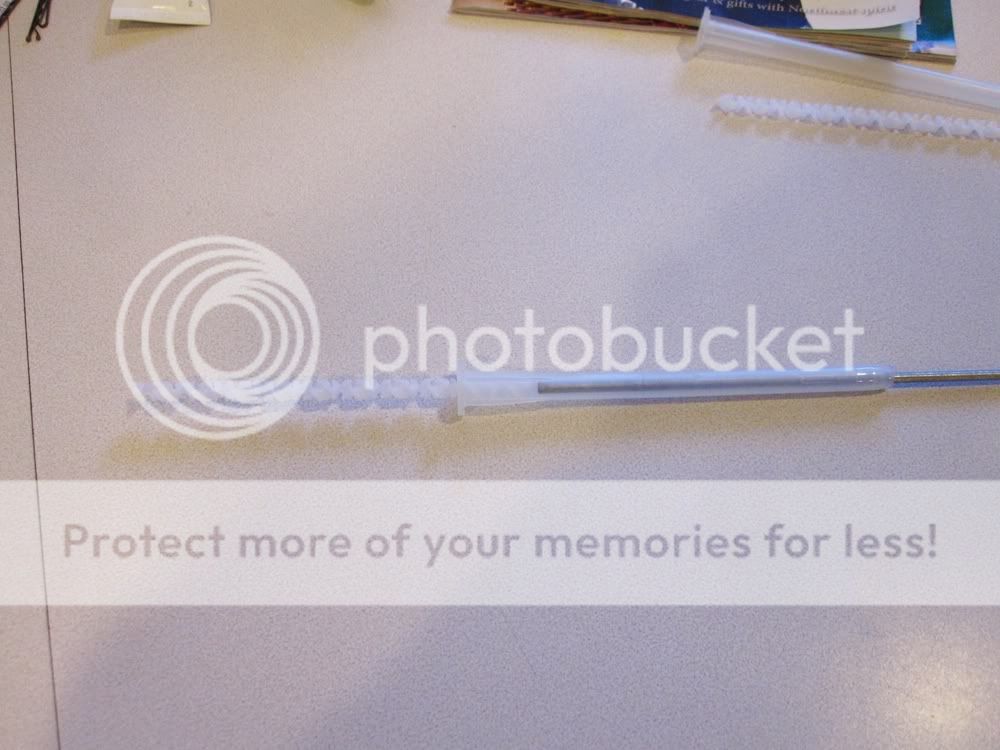

Close up of the swizzle thru tube

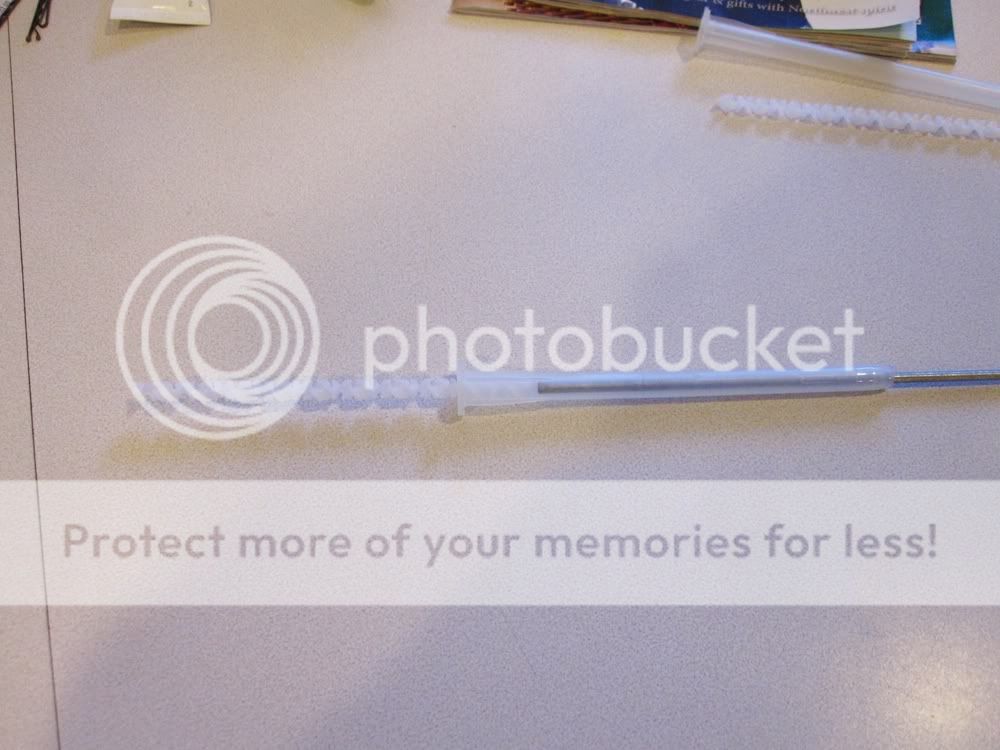

Tube/swizzle with wire I used to push swizzle out

Wire entering from tapered end of tube

Wire pushing swizzle out open end

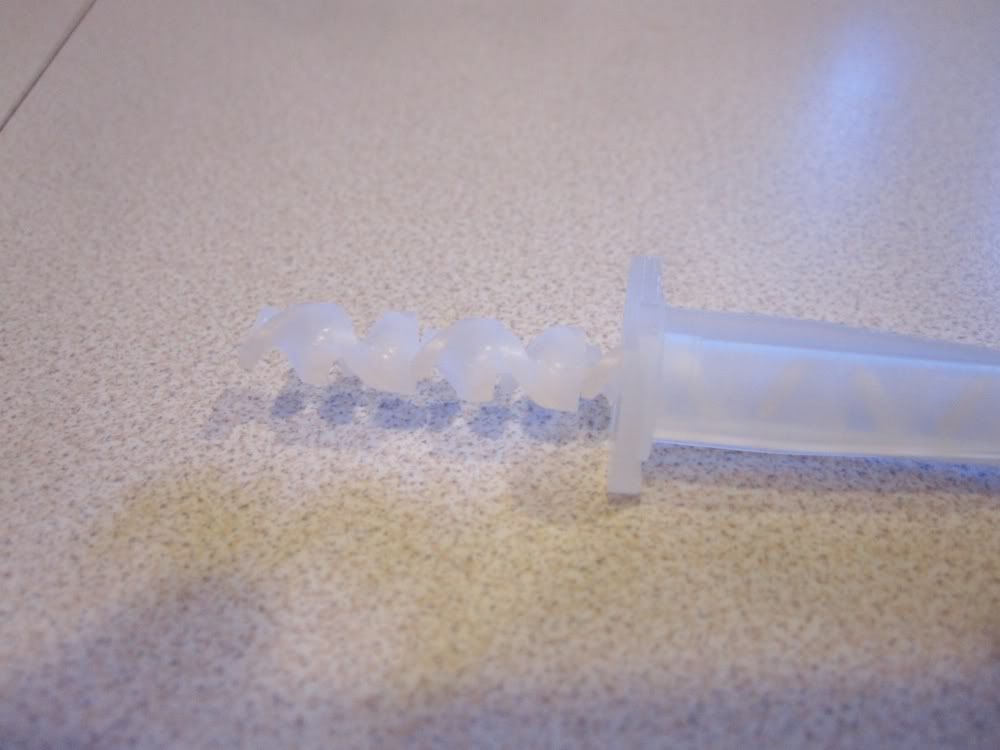

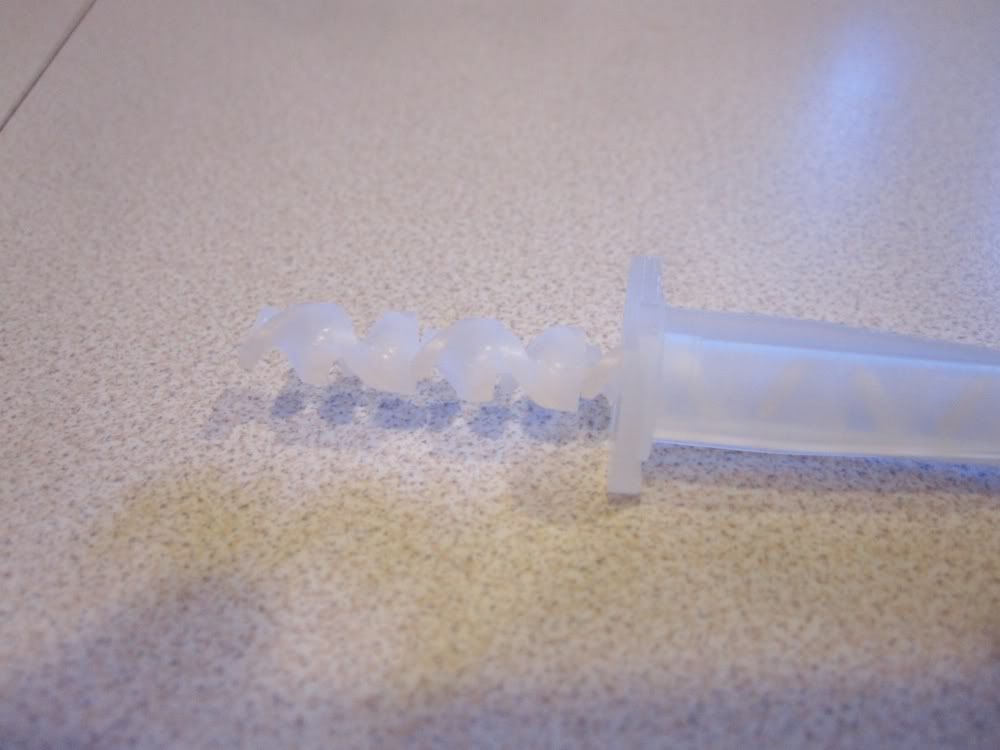

Close up of swizzle coming out open end

Swizzle most of the way out

Swizzle out of the tube

Quarter for scale of swizzle (I thought they would be much shorter than they are)

While reading all of the pages in this thread, I had a hard time picturing what the swizzle sticks were like, until someone posted a pic of one and that helped a lot. In my reading, I also saw that many people were having trouble picturing how to get the swizzle out of the shaft it comes in, so I took some pics at various points in the process of taking the swizzle out. Believe me, it's a very easy and fast process, but just to give people an idea of what they will be doing, I thought I would post the pics here as an "illustrated tutorial", or whatever. I hope it helps.

Just some background, my beer is a stout at about 38*F at 10psi. It's in a ball lock keg with about 5ft of tubing with a party tap at the end, typical of kegconnection.

Funnily enough, I have yet to insert the swizzles in my keg as I'm waiting for the beer to get back to being carbed. It had gotten over carbed so I released all the pressure, "flattened" it out and then recarbed it using the "set and forget" technique. Wish me luck when I actually put them in.

The tube with the swizzle still inside

Close up of the swizzle thru tube

Tube/swizzle with wire I used to push swizzle out

Wire entering from tapered end of tube

Wire pushing swizzle out open end

Close up of swizzle coming out open end

Swizzle most of the way out

Swizzle out of the tube

Quarter for scale of swizzle (I thought they would be much shorter than they are)

Brewed Hefeweizen.

Filled a cup to clear line then got out a frosted glass. Used 2 full length mixer sticks and got 3/4 cup of foam w/ 24 psi @ ~34F and 5' hose shooting for 4 vol co2. Any suggestions?

Frosted glass = beau coup nucleation sites. What happens if you use a rinsed glass?

Cheers!

mrgstiffler

Well-Known Member

Brewed Hefeweizen.

Filled a cup to clear line then got out a frosted glass. Used 2 full length mixer sticks and got 3/4 cup of foam w/ 24 psi @ ~34F and 5' hose shooting for 4 vol co2. Any suggestions?

What size tubing?

what size tubing?

1/2" od

1/2" od

What does that translate into for inside diameter?

Unless you're sending beer like 20 feet from the keg, 3/16" ID is the appropriate tubing...

Cheers!

ultravista

Well-Known Member

24 PSI? Holy smokes ...

What does that translate into for inside diameter?

Unless you're sending beer like 20 feet from the keg, 3/16" ID is the appropriate tubing...

Cheers!

Pretty sure it is 1/4 " ID, sounds like I may need to change the line if 3/16 is ideal. Its only going up and out the kegerator tower.

mrgstiffler

Well-Known Member

Pretty sure it is 1/4 " ID, sounds like I may need to change the line if 3/16 is ideal. Its only going up and out the kegerator tower.

3/16" will add more restriction to the line, meaning you'll get less foam. It wont be perfect though. At 4 volumes, my kegerator will pour about 3/4 glass beer with 2 and a half mix sticks.

3/16" will add more restriction to the line, meaning you'll get less foam. It wont be perfect though. At 4 volumes, my kegerator will pour about 3/4 glass beer with 2 and a half mix sticks.

I could handle that. I went ahead and added 2 sticks (4 total) to see if it is a little better. Thanks for your info.

mrgstiffler

Well-Known Member

Changed the 1/4" ID to 5' of 3/16 ID line with 4 mixer sticks. 95% foam at ~34F and 20 psi. Any ideas?

And you're pouring out the first half glass of foam?

Bk2X said:i did 4 glasses back to back

I would check your o-ring on the liquid dip tube... Depressurize and unscrew the male QD and ensure the o-ring is seating correctly!!

Bruin

Well-Known Member

I put four sticks in a keg of carbonated water at 30 psi. Faucet is right on the keg with a quick disconnect adaptor, no hose at all for this keg. Nice easy slow pour.

i did 4 glasses back to back

The last time I read of someone with a similar, baffling foam problem, it turned out the Out dip tube had a hole in it...

Cheers!

Snood

Well-Known Member

I can't find these anywhere in Europe at anything like a reasonable price. Does anyone have any suggestions? I live in Sweden but have family in the UK so can buy there too.

Failing that, it's a long shot but is there someone in the US who can send me some (i'll pay of course)

Failing that, it's a long shot but is there someone in the US who can send me some (i'll pay of course)

Similar threads

- Replies

- 6

- Views

- 771

- Replies

- 69

- Views

- 2K

- Replies

- 30

- Views

- 815