On demand water heaters are the way to go! We use some at work that max out at 185degF. One of those babies could be an instant never ending HLT.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

55 Gallon AE Kettle system

- Thread starter wadefisher

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If you have access to steam, you should be able to Frankenstein a 3-7bbl brewery together fairly cheep. Spend your money on fermenters though.

http://www.ebay.com/itm/GROEN-150-G...337?pt=LH_DefaultDomain_0&hash=item3367a9fb99

Yes Bsquared I agree. My first 2 are from Stout Tanks. 125 Gallons each.

Forget 3 phase. No need to mess with that if you dont have to. Everything is more expensive. Stick to single phase. I used 3 4500w elements in my boil kettles. I ran a 60a circuit to each kettle. I too used 55 gallon drums. I easily boiled 50 gallon batches. You just need to skim the hot break and watch the boil closely. I had two boil kettles and I was able to get a finished batch of 75 gallons after all transfers.

With your 3 4500w elements do you need to put a potentiometer on it to control the boil? Or just ON/OFF switch.

Also I see you are boiling 50 Gallons. Do you use a foaming additive? I always use a product like Fermcap-S in my 10 gallon systems.

What do you use for a MLT if you have 2 boil kettles? Since I have 3 barrel fermenters coming I figured a 1.5 barrel 55 gallon system run 2 batches in one day. Maybe I should configure the MLT to handle more and make 2 boil kettles.

lamarguy

Well-Known Member

Any reason for not using two three phase SSRs?

And, I assume you don't plan to do step mashes since you're not including a MLT heat source.

And, I assume you don't plan to do step mashes since you're not including a MLT heat source.

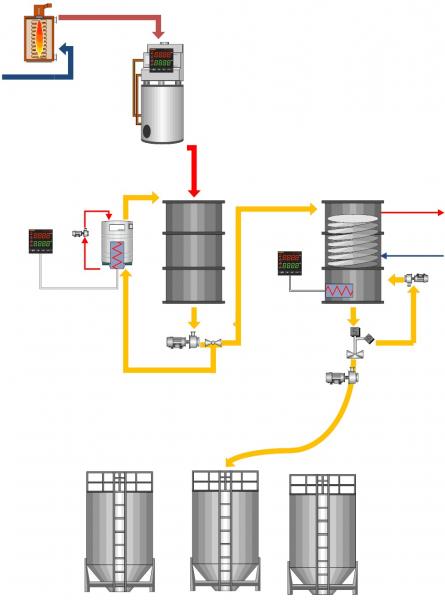

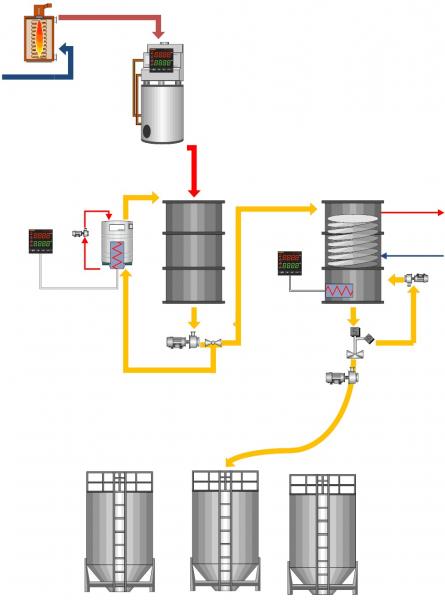

P-J Thanks very much for the diagram. It is greatly appreciated

With your 3 4500w elements do you need to put a potentiometer on it to control the boil? Or just ON/OFF switch.

Also I see you are boiling 50 Gallons. Do you use a foaming additive? I always use a product like Fermcap-S in my 10 gallon systems.

What do you use for a MLT if you have 2 boil kettles? Since I have 3 barrel fermenters coming I figured a 1.5 barrel 55 gallon system run 2 batches in one day. Maybe I should configure the MLT to handle more and make 2 boil kettles.

Sorry for the late reply, I had 2 MLT's I sorta did a modified batch/fly sparge to make it work. Using the extra boil kettle to heat water. I would batch sparge what was left in first BK. Then I would start transfer from MLT to that kettle. Then I would fly sparge the whole 50 gallons from the second BK into the first MLT. When I was filled in the first BK I would start transfer from second MLT to second BK. Then I would sparge with what was left in the first mlt to the second mlt. It was a pain but it worked well.

I did not use foam control just very carefully watched the boil for the first 15 minutes and tried my best to skim the hot break. Its strange but my 7bbl kettle is violent. I have to use fermcap-S to keep it under control. I think that might be the difference between electric and direct fire.

I did use a Pot to control the kettles. I made a PWM circuit for both kettles.

Three phase SSRs are out of this world expensive. But you can try China and wait 2 months - No? (And then wait on the quality of the produce and its reliability?)Any reason for not using two three phase SSRs?

And, I assume you don't plan to do step mashes since you're not including a MLT heat source.

Step mashing requires a completely different setup. RIMS becomes fairly expensive and complicated to control. There are too many variables to be able to control accurate and repeatable results. Also, IMHO, you do not want to ever directly heat the MLT. That's just me, apparently.

If you are dead set on step mashing, control the HLT temp and use a HERMS coil to accomplish the task. With a 3 phase setup it would be easy to drive the HLT temps up very rapidly.

Mission accomplished.!

IMHO

lamarguy

Well-Known Member

Three phase SSRs are out of this world expensive. But you can try China and wait 2 months - No? (And then wait on the quality of the produce and its reliability?)

A 40A three phase SSR is around $150. Not unreasonable.

RIMS becomes fairly expensive and complicated to control. There are too many variables to be able to control accurate and repeatable results. Also, IMHO, you do not want to ever directly heat the MLT.

Commercial breweries use steam-jacketed mash tuns as the norm. Also, a RIMS/HERMS is dead simple to control with a PID and a temperature probe near the exit.

Good luck with your build.

A 40A three phase SSR is around $150. Not unreasonable.

Commercial breweries use steam-jacketed mash tuns as the norm. Also, a RIMS/HERMS is dead simple to control with a PID and a temperature probe near the exit.

Good luck with your build.

Not my build. I developed a diagram for the OP.

BTW: $150 for a 3 phase SSR is a boat load more $'s than using either single or dual SSRs for the same result.

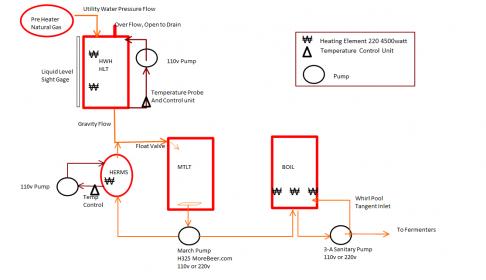

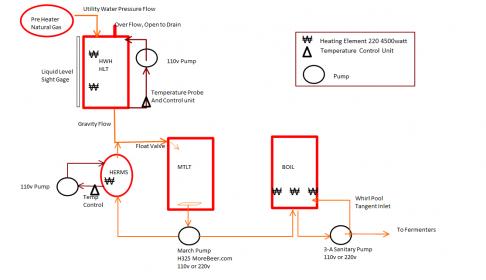

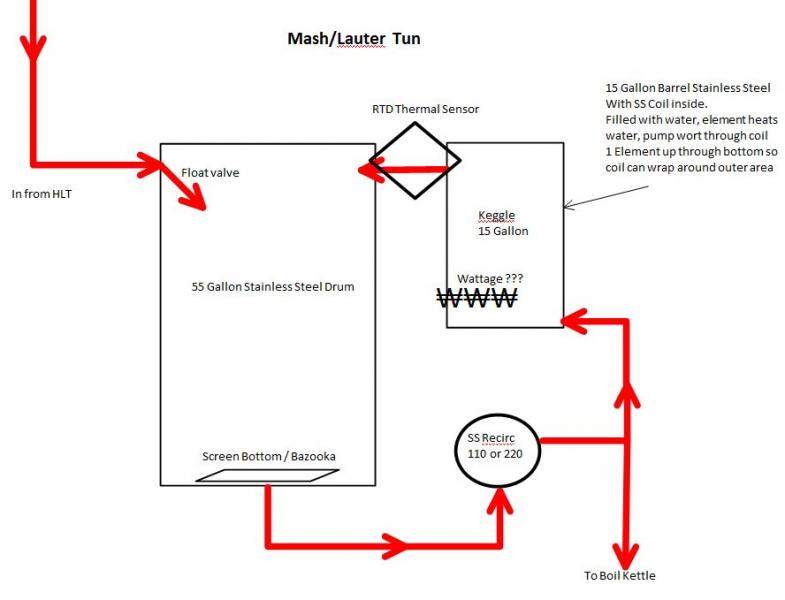

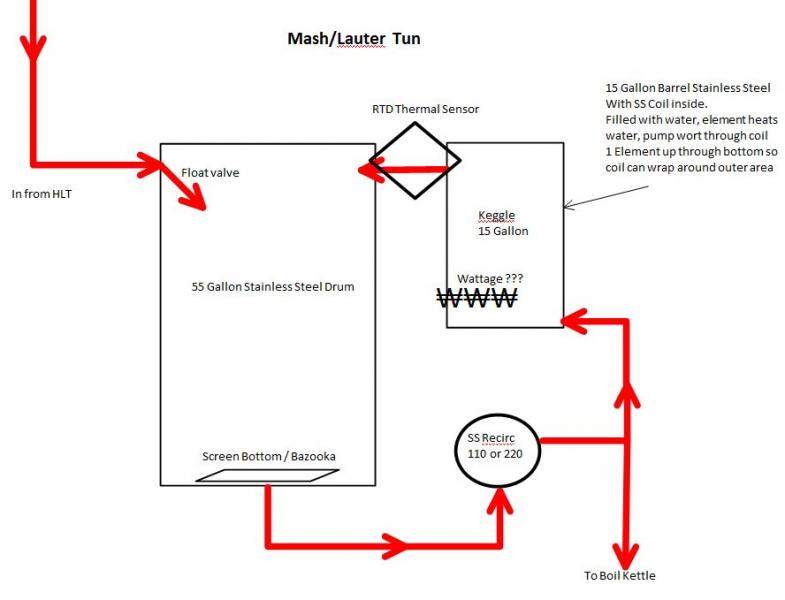

Here is what I'm leaning towards right now. I still am in the early stages of planning. Will most likely start the build the end of October.

Let me try to upload the diagram again.

P-J; the 3 phase 18000 watt elements are like 3 feet long. So they are out.

I'm leaning towards these mounts from Brewers Hardware . com They will be easily removed for cleaning. Allowing me to use 220 v 4500 watt elements and these adapters look more water tight than the units I have already.

I'm leaning towards these mounts from Brewers Hardware . com They will be easily removed for cleaning. Allowing me to use 220 v 4500 watt elements and these adapters look more water tight than the units I have already.

I think that is a good plan. All you would need to do to run on 240V - 3 phase power is to install 3 elements in eack kettle. I'll have to do some digging for 480V - 3 phase power but I think you would also need 3 elements (in a "Y" configuration) in each kettle.P-J; the 3 phase 18000 watt elements are like 3 feet long. So they are out.

I'm leaning towards "these mounts" from Brewers Hardware . com They will be easily removed for cleaning. Allowing me to use 220 v 4500 watt elements and these adapters look more water tight than the units I have already.

If you plan on either setup, I'd be glad to mod the diagran for you.

P-J

I think that is a good plan. All you would need to do to run on 240V - 3 phase power is to install 3 elements in eack kettle. I'll have to do some digging for 480V - 3 phase power but I think you would also need 3 elements (in a "Y" configuration) in each kettle.

If you plan on either setup, I'd be glad to mod the diagran for you.

P-J

Here is where I personally am a little fuzzy. What's the difference between 220v Single phase vs 240v 3 phase. Can I use regular 220v HWH elements?

P-J your input has already been a lot of help. I've looked at your wire schematics in several treads to get ideas for what I want to do.

I did the "digging" and it will not work out using 240V elements on 480V 3 phase power unless you use a total of 6 elements per kettle. 240V 3 phase is A-ok....

I'll have to do some digging for 480V - 3 phase power but I think you would also need 3 elements (in a "Y" configuration) in each kettle.

...

208 vs 220 vs 240 is really all the same thing. It all depends on how the power is delivered to your facility. It starts with how the power company configures the transformers with a 'Delta' or 'Y' feed. The elements are rated for 240V and will work just fine.Here is where I personally am a little fuzzy. What's the difference between 220v Single phase vs 240v 3 phase. Can I use regular 220v HWH elements?

P-J your input has already been a lot of help. I've looked at your wire schematics in several treads to get ideas for what I want to do.

P-J;

The instruction sheet for SYL-2352 PID (2011.02 P7/8) shows an example of a 240VAC heating application. They have L1 on [9] and L2 on [10]

On schematics you have done I see you put L1 on [10] and Neutral on [9]

What is the difference?

The instruction sheet for SYL-2352 PID (2011.02 P7/8) shows an example of a 240VAC heating application. They have L1 on [9] and L2 on [10]

On schematics you have done I see you put L1 on [10] and Neutral on [9]

What is the difference?

It really does not matter. It can be done that way as well. However, I show the PID being powered with 120V AC. This saves a little bit on switches as a double pole switch in not requires for 120V AC. With 240V PID power, it should be powered through a double pole switch so that the PID is isolated when off.P-J;

The instruction sheet for SYL-2352 PID (2011.02 P7/8) shows an example of a 240VAC heating application. They have L1 on [9] and L2 on [10]

On schematics you have done I see you put L1 on [10] and Neutral on [9]

What is the difference?

IMHO.

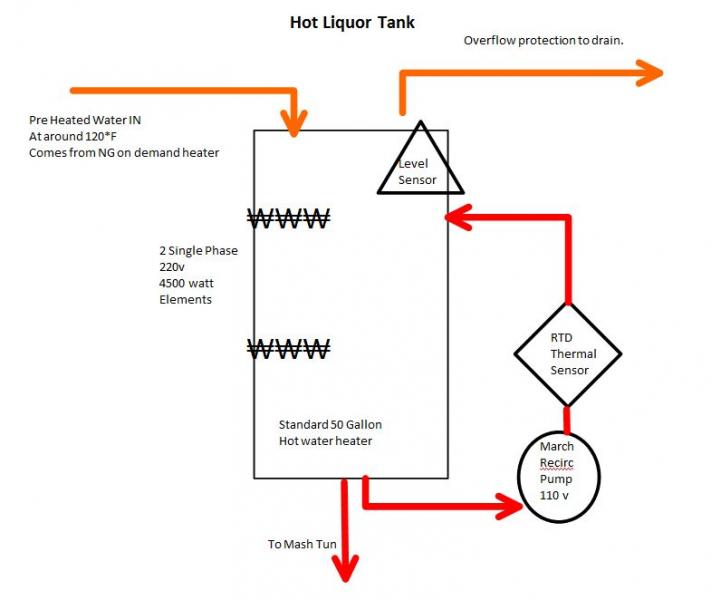

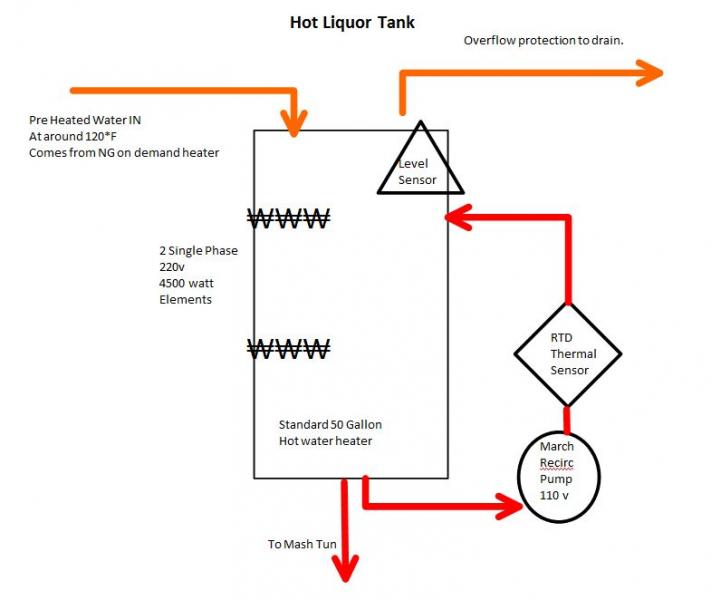

HLT/HWH Control unit;

Each tank control unit will be independent from each other.

This will keep the system modular. I expect a lot of changes over the next year or so.

The HLT is a 50 gallon standard Hot water heater. I will remove the built in thermostats.

I will also make sure the system is 'open' so as not to be able to build up pressure.

And it will still have a pressure release valve built in.

It is filled manually by turning on a ball valve for filling with preheated water.

There is an overflow pipe to a near by drain. (Figured this out the hard way.)

Water is circulated from the bottom to the top by a March pump. This prevents temperature variations.

The Sensor is fitted into the recirculation pipe.

A sight glass is attached to know the fill level and to measure the amount being infused into the mash.

I will have this higher than the MLT so I can gravity sparge. But it could be pumped easily if I want to lower it.

I have allreay made a 20 gallon unit like this and used a purchased controller.

Here is what is needed from the control unit:

1) Power feed In; 220v Single phase

2) Control unit power on/off at incoming point. Lighted push button to 220 relay.

Auber SW1 Red and Contactor, 2 pole 40 A, 240V coil CN-PBC402-240V

3) Single SYL-2352 PID temperature controller

Pt100 RTD Sensor

4) Single SSR to single 220v output to power 1 or 2 4500watt elements

Auber 40 A SSR RS1A40D40

5) Water level protection switch.

Elements can not come on if water is below minimum level.

http://www.mcmaster.com/#liquid-level-switches/=e7tysr

and http://www.mcmaster.com/#liquid-level-switches/=e7u3yj

6) Indicator light when power is being suppied to heating elements

7) Over Temp Alarm

Flashing Buzzer Auber FLBuz

7) 2 Switched pump controls. 1 for Recirculation , 1 for future use.

110v Outlets

Auber SW1 Blue

What would be the advantage of a 4 wire system vs 3 wire?

Can you indicate the wire gauges needed inside the control panel?

P-J if you can design my control panels, I will upgrade your account to LifeTime Supporter. Or whatever else I can do for you.

Each tank control unit will be independent from each other.

This will keep the system modular. I expect a lot of changes over the next year or so.

The HLT is a 50 gallon standard Hot water heater. I will remove the built in thermostats.

I will also make sure the system is 'open' so as not to be able to build up pressure.

And it will still have a pressure release valve built in.

It is filled manually by turning on a ball valve for filling with preheated water.

There is an overflow pipe to a near by drain. (Figured this out the hard way.)

Water is circulated from the bottom to the top by a March pump. This prevents temperature variations.

The Sensor is fitted into the recirculation pipe.

A sight glass is attached to know the fill level and to measure the amount being infused into the mash.

I will have this higher than the MLT so I can gravity sparge. But it could be pumped easily if I want to lower it.

I have allreay made a 20 gallon unit like this and used a purchased controller.

Here is what is needed from the control unit:

1) Power feed In; 220v Single phase

2) Control unit power on/off at incoming point. Lighted push button to 220 relay.

Auber SW1 Red and Contactor, 2 pole 40 A, 240V coil CN-PBC402-240V

3) Single SYL-2352 PID temperature controller

Pt100 RTD Sensor

4) Single SSR to single 220v output to power 1 or 2 4500watt elements

Auber 40 A SSR RS1A40D40

5) Water level protection switch.

Elements can not come on if water is below minimum level.

http://www.mcmaster.com/#liquid-level-switches/=e7tysr

and http://www.mcmaster.com/#liquid-level-switches/=e7u3yj

6) Indicator light when power is being suppied to heating elements

7) Over Temp Alarm

Flashing Buzzer Auber FLBuz

7) 2 Switched pump controls. 1 for Recirculation , 1 for future use.

110v Outlets

Auber SW1 Blue

What would be the advantage of a 4 wire system vs 3 wire?

Can you indicate the wire gauges needed inside the control panel?

P-J if you can design my control panels, I will upgrade your account to LifeTime Supporter. Or whatever else I can do for you.

This is very doable. Just give a little time to put together another diagram set for you.

What is your plan for the boil kettle?

What is your plan for the boil kettle?

This is very doable. Just give a little time to put together another diagram set for you.

What is your plan for the boil kettle?

Thanks P-J

I'm getting the outline for the Mash Tun HERMS and the Boil Kettle. But they will all be independently controlled. That way if we change the system configuration we won't have controls tied together. I want to keep it modular.

I think right now I am wanting to do 3 220v single phase 4500 watt heating elements. Just seems simple, unless you think we have an advantage to putting 3 phase to it.

Thanks P-J

I'm getting the outline for the Mash Tun HERMS and the Boil Kettle. But they will all be independently controlled. That way if we change the system configuration we won't have controls tied together. I want to keep it modular.

I think right now I am wanting to do 3 220v single phase 4500 watt heating elements. Just seems simple, unless you think we have an advantage to putting 3 phase to it.

If you are intending to use 3 elements in any vessel, 3 phase will be less expensive both in the build and in the cost of power to run it.

Regarding the 3 phase you might have available. Is there any way tjhat you can determine what is actually available. If your power is 480V 3 phase the question becomes is that 480 power or 240/480 power or is it 277/480 power. I'm trying to determine how the 3 phase power is being delivered to your place, i.e is it by a Delta or "Y" transformer connections.

The other possibility is if you have 240V 3 phase available.

Single elements are certainly available for your use in the system. Check out this sites lists of high quality elements:

http://bostonheatingsupply.com/rheemelectricelements.aspx

I'll help you in any way that I can. I believe this to be a fun journey for me and it also keeps this old timer from becoming an alsheimer.

If you are intending to use 3 elements in any vessel, 3 phase will be less expensive both in the build and in the cost of power to run it.

Regarding the 3 phase you might have available. Is there any way tjhat you can determine what is actually available. If your power is 480V 3 phase the question becomes is that 480 power or 240/480 power or is it 277/480 power. I'm trying to determine how the 3 phase power is being delivered to your place, i.e is it by a Delta or "Y" transformer connections.

The other possibility is if you have 240V 3 phase available.

Single elements are certainly available for your use in the system. Check out this sites lists of high quality elements:

http://bostonheatingsupply.com/rheemelectricelements.aspx

I'll help you in any way that I can. I believe this to be a fun journey for me and it also keeps this old timer from becoming an alsheimer.

We have both, there are 3 separate transformers. I have to find out which is more accessible to the area I have mapped out for the brewery area.

P-J

Thanks for the link. That is what I was trying to find earlier, without success. I will have the transformer info soon. I will send you some 'homebrew' PM me your address.

Thanks alot

Wade

Thanks for the link. That is what I was trying to find earlier, without success. I will have the transformer info soon. I will send you some 'homebrew' PM me your address.

Thanks alot

Wade

P-J the panel closest to the brew room is 480v 3 phase. I have my electrician commming over soon to find out what type of 3 phase.

I have started working with Auber's PID's on 2 projects to get familiar with them. I am building a control to run my 10 gallon system in Florida and to control an incubator for my bee farm. I will post pics shortly.

I have started working with Auber's PID's on 2 projects to get familiar with them. I am building a control to run my 10 gallon system in Florida and to control an incubator for my bee farm. I will post pics shortly.

OK, electrician says its 'Y' on the 3 phase 480v panel. Have a panel nice and accessible to the 'brew room' that is 3 phase 480v 'Y' and it has space to tap in. That is good news for me. I was afraid I would have to run in a new panel from the MAIN which is 200 feet away. That could be $$$$ that I would rather spend on beer toys.

this is insane!!!!

(in a good way)

hammis; I'm not sure if I have gone crazy or not

but I'm doing this!

but I'm doing this!Diagram of HLT

MTLT

Element size and wattage to be determined.

Pump always runs, just need an ON/OFF switch. But Pump should have to be ON to allow heating elements to fire.

Will use a PID with 'Ramp/Soak" functions to allow for multi-step mashing.

Separate Control panel for each tank will allow easy changes is equipment as needed.

Element size and wattage to be determined.

Pump always runs, just need an ON/OFF switch. But Pump should have to be ON to allow heating elements to fire.

Will use a PID with 'Ramp/Soak" functions to allow for multi-step mashing.

Separate Control panel for each tank will allow easy changes is equipment as needed.

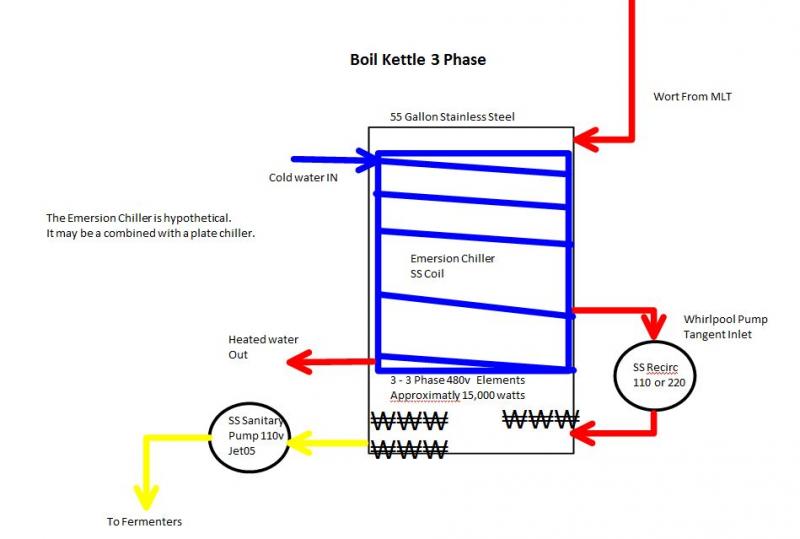

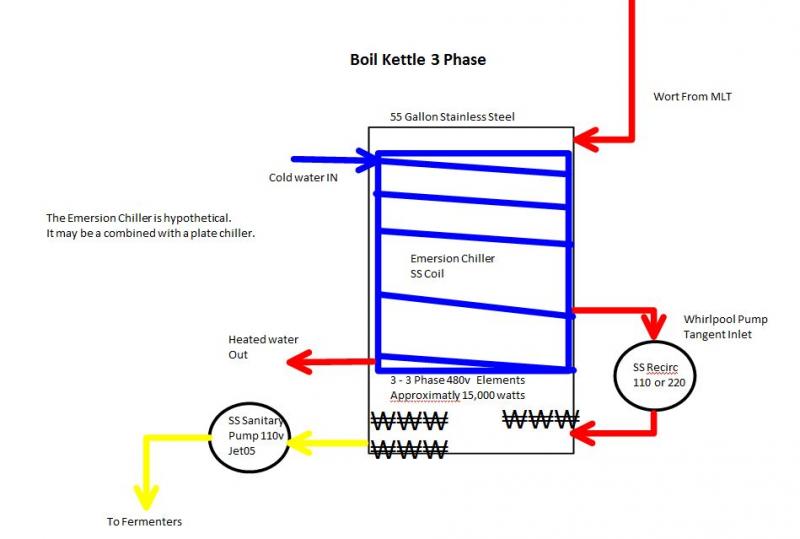

Boil Kettle;

I'm not sure if the 'immersion' style cooler is possible, but I am going to experiment. Because of the problem with other style coolers allowing the wort in the boil kettle to sit at high temperatures until they get pumped through. I think it may be a combination of the 2.

The control panel here mainly needs to allow variable power to heating elements to control boil intensity and 1 pump switch for the whirlpool. IThe Jet 05 Sanitary pump is mobile and has its own built in power switch.

I'm not sure if the 'immersion' style cooler is possible, but I am going to experiment. Because of the problem with other style coolers allowing the wort in the boil kettle to sit at high temperatures until they get pumped through. I think it may be a combination of the 2.

The control panel here mainly needs to allow variable power to heating elements to control boil intensity and 1 pump switch for the whirlpool. IThe Jet 05 Sanitary pump is mobile and has its own built in power switch.

Another Diagram

thelema420

Member

not sure if this is relevant or not, but last time i checked ebay had some 100 gallon stainless tanks listed for like $500. they are in NC and pickup only and no they aren't mine.

orangehero

Well-Known Member

It seems you will be using a seperate HERMS vessel to maintain mash temperature. If so, you may want to consider using a 5 gallon vessel (like a corny keg) instead of the 15 gal sanke. It will make it easier and quicker to raise the temperature of the mash.

Like in this thread.

Like in this thread.

Henrythe9th

Well-Known Member

You won't be able to clean your boil pot with you I'M chiller design,

15.5gal Herms 50' 7/8 Copper or Stainle$$ coil will work, 2500w depends on volts I would use a stir motor on the HLTand HERMS, use 1 1/2 tri clover fitting everywhere

To my under standing 3ph Elec is good for motors ie-3 phases, but on heaters a 3 ph system uses 3 elements 1 for each phase so only voltage is the advantage.

Our 500gal. HLT is 240v 3PH and has 3 elements totaling 15KW

There are 4 5500w 220v elements in our 5bbl boil pot, 22KW using 94 amps

Spend money on Fermentors and a real Plate chiller and Glycol sys. and more

15.5gal Herms 50' 7/8 Copper or Stainle$$ coil will work, 2500w depends on volts I would use a stir motor on the HLTand HERMS, use 1 1/2 tri clover fitting everywhere

To my under standing 3ph Elec is good for motors ie-3 phases, but on heaters a 3 ph system uses 3 elements 1 for each phase so only voltage is the advantage.

Our 500gal. HLT is 240v 3PH and has 3 elements totaling 15KW

There are 4 5500w 220v elements in our 5bbl boil pot, 22KW using 94 amps

Spend money on Fermentors and a real Plate chiller and Glycol sys. and more

I am still in the thought process of how that would work.You won't be able to clean your boil pot with you I'M chiller design,

Yes, stir motors already figured in on these.15.5gal Herms 50' 7/8 Copper or Stainle$$ coil will work, 2500w depends on volts I would use a stir motor on the HLTand HERMS,

YES, already have large supply.use 1 1/2 tri clover fitting everywhere

Several option for hooking up, went over it with my electrician. Easier to make the runs because less copper and conduit. And I have a panel close by the Brew Room that has extra room.To my under standing 3ph Elec is good for motors ie-3 phases, but on heaters a 3 ph system uses 3 elements 1 for each phase so only voltage is the advantage.

Good info, thanksOur 500gal. HLT is 240v 3PH and has 3 elements totaling 15KW

There are 4 5500w 220v elements in our 5bbl boil pot, 22KW using 94 amps

Yes agreed. Any suggestions on the Plate chiller.Spend money on Fermentors and a real Plate chiller and Glycol sys. and more

EarthBound

Well-Known Member

I got fever, and the only cure is some pictures of your equipment!

I'm looking to you (among others) when it comes to opening my commercial brewery. Just sayin...

I'm looking to you (among others) when it comes to opening my commercial brewery. Just sayin...

I got fever, and the only cure is some pictures of your equipment!

I'm looking to you (among others) when it comes to opening my commercial brewery. Just sayin...

Comming soon, Just moved from planning to building phase this week.

Okay, Construction is underway. Built a wall to section off brewery area. Raised ceiling height to accomadate process. Notice I luckily already have tile floor in this room.

Similar threads

- Replies

- 2

- Views

- 669

- Replies

- 23

- Views

- 1K

- Replies

- 0

- Views

- 501